Content

Page

Declaration of incorporation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

1. General

1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Scope of guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 Qualification and training of staff. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.3 Hazards in case of non-observance of the safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.4 Owner‘s / operator‘s obligations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.5 Safety instruction for maintenance, inspection and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.6 Unauthorized modification and production of spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.7 Inadmissible modes of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.8 Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.9 General hazard warning - residual risk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Use of hydraulic hose lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Technical data FKGGM-EPR /EPR

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Functional description

3.1 Function and setup of a central lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.1 Function and setup of a progressive central lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.2 Function and setup of a single line central lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Function of the central lubrication pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

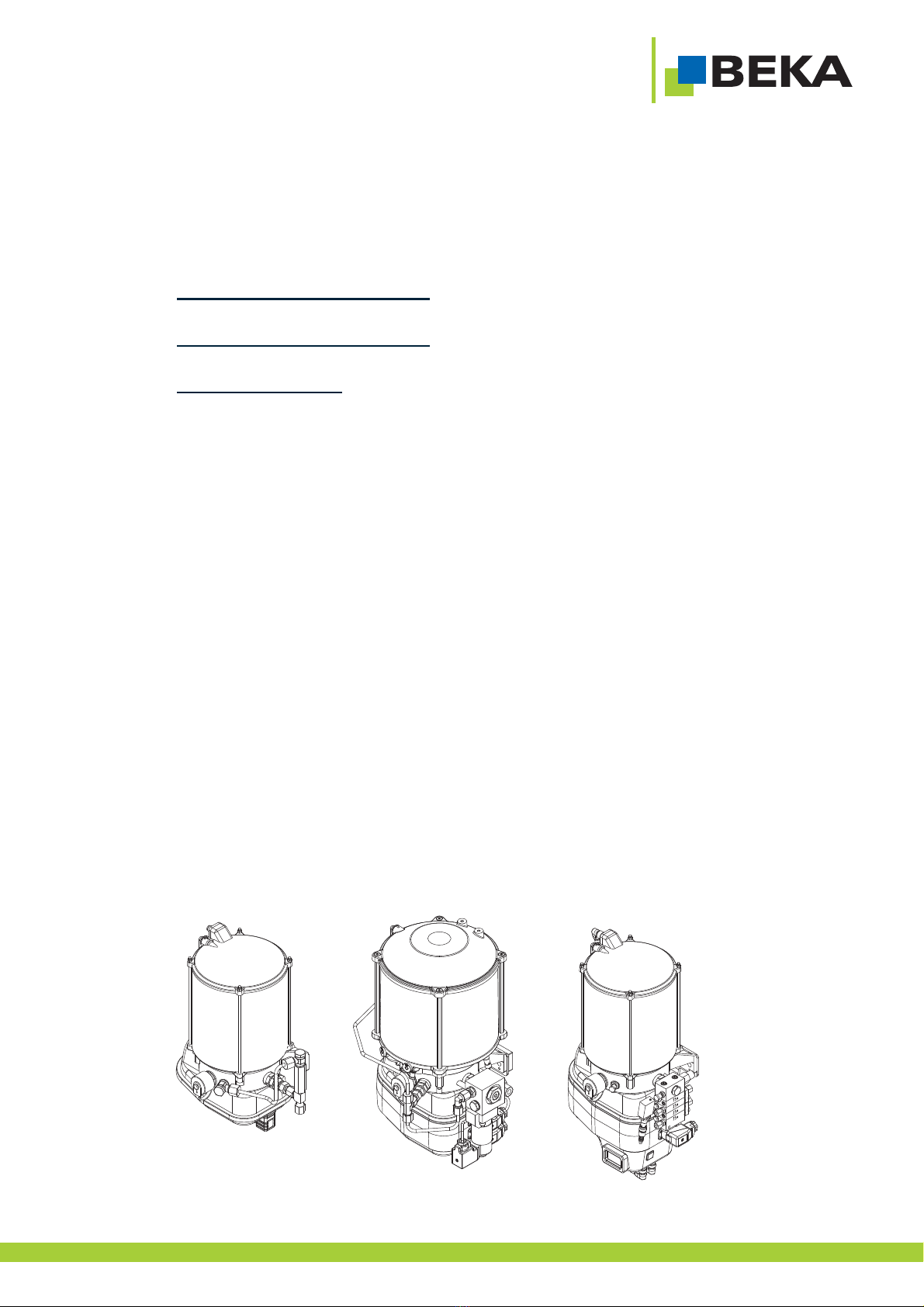

3.2.1 Central lubrication pump FKGGM - EP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Central lubrication pump FKGGM - EPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3 Central lubrication pump FKGGM - EP / EPR with installed MX-F distributor . . . . . . . . . . . . . . . . 15

3.3 Pump element (PE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

3.3.1 Pump elements PE-60, PE-120 und PE.170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 Pump element PE-120 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.3 Pu tral lubrication pumps for single line systems. . . . . . 19-20mp element with solenoid valve at cen

4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Installation dimensions

Installation dimensions of construction variation of motor housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Central lubrication pump FKGGM - EP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1.1 Central lubrication pump FKGGM - EP 1,9 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1.2 Central lubrication pump FKGGM - EP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1.2.1 2,5 liter reservoir - without level monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1.2.2 2,5 liter reservoir - with level monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.2.3 2,5 liter reservoir - with filling cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.3 Central lubrication pump FKGGM - EP 4 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.4 Central lubrication pump FKGGM - EP 8 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.5 Central lubrication pump FKGGM - EP 12 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.6 Central lubrication pump FKGGM - EP 16 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1.7 Central lubrication pump FKGGM - EP 20 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.8 Central lubrication pump FKGGM - EP 30 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Central lubrication pump FKGGM - EPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.1 Central lubrication pump FKGGM - EPR 4 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.2 Central lubrication pump FKGGM - EPR 8 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.3 Central lubrication pump FKGGM - EPR 12 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.4 Central lubrication pump FKGGM - EPR 15 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.5 Central lubrication pump FKGGM - EPR 20 liter reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3 Central lubrication pump FKGGM - EP with installed MX-F distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34Accessories

5.1 Level monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.1 FKGGM-EP pump - Proximity switch with plug-type connection M12x1 - 10-60 V/DC: . . . . . . . . . 34

5.1.2 FKGGM-EP pump - Proximity switch with plug-type connection M12x1 - 90-250 V/AC. . . . . . . . . 35

5.1.3 FKGGM-EP pump - Proximity switch - connection cubic plug acc. to DIN 43650 . . . . . . . . . . . . . 35

5.1.4 FKGGM-EPR pump - Proximity switch with plug-type connection M12x1 . . . . . . . . . . . . . . . . . . . 36

5.1.5 FKGGM-EPR pump - Ultrasonic sensor with plug-type connection M12x1 . . . . . . . . . . . . . . . . . . 37

5.2 Micro switch at pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2

Subject to alterations!

...a product from

BAL2076_central lubrication pump_0119EN

© BEKA 2019 All rights reserved