!These instructions must be read and understood by all

persons who are involved with the installation, operation,

maintenance, and repair of the product. These instructions must

be kept close to the equipment for future reference.

Note that these installation instructions is an integral part of

the product. It must be handed over to the new operator of the

product if the product is sold.

!In addition to the information provided in the installation

instructions, all generally applicable regulations on acci-

dent prevention and the environment must be observed.

!All products from SKF may be used only for their intended

purpose as described in this brochure and in any

instructions.

DANGER!

Working on products that have not been disconnected

from the power supply can cause serious injury or death to per-

sons. Installation, maintenance, and repair work may only be

carried out by qualified experts on products that have been dis-

connected from the power supply. The supply voltage must be

turned off before any product components are opened. .

DANGER!

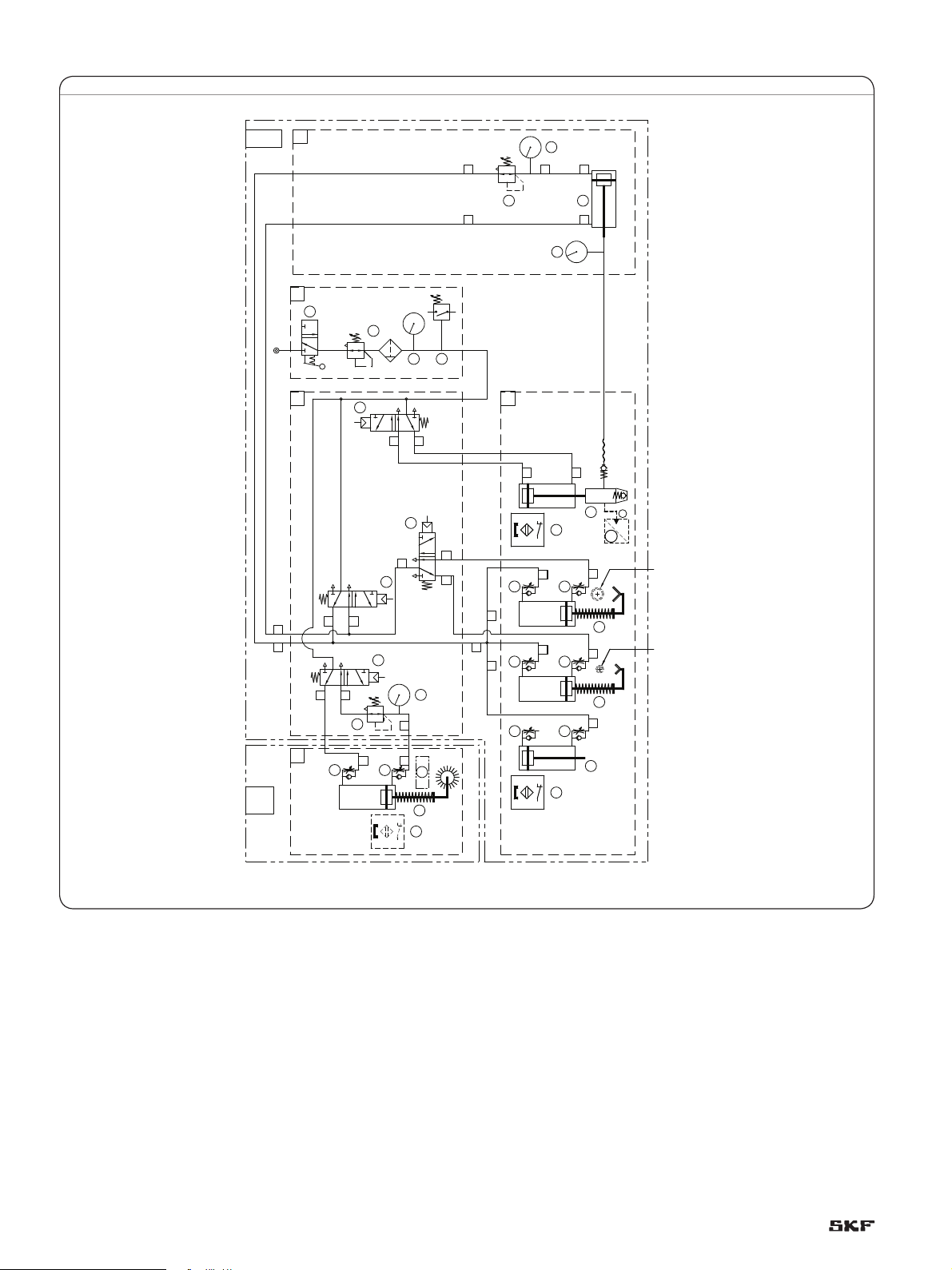

Centralized lubrication systems are under pressure when

they are being operated. Such systems must therefore be de-

pressurized before starting installation, maintenance, or repair

work and before making any changes to the system.

1 Safety instructions

The described product was manufactured in accordance with all

generally acknowledged regulations pertaining to technology, occu-

pational safety, and accident prevention. However, dangers that can

cause physical injury to persons or damage to other material assets

might still occur during the use of the product.

1.1 Intended use

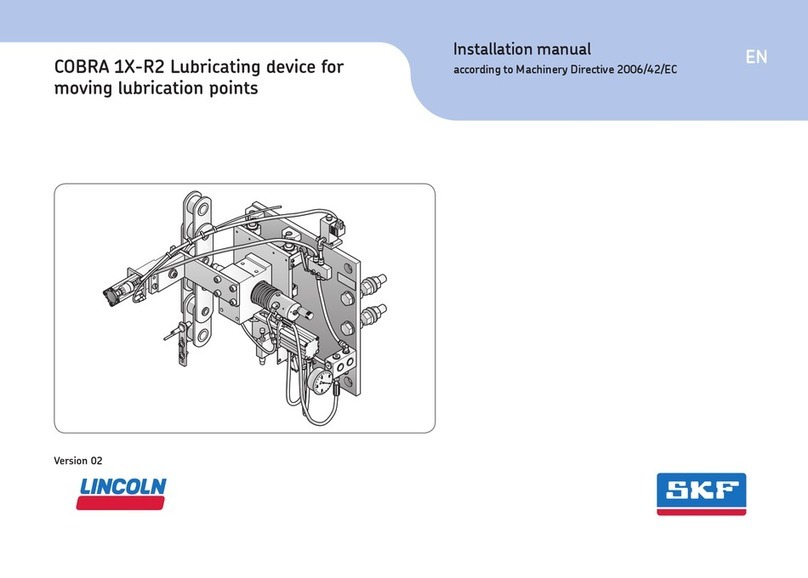

The described product is for supplying centralized lubrication sys-

tems with lubricant and is intended for use in centralized lubrication

systems. Other use or use beyond this purpose is considered

unintended.

Products of SKF must not be used in conjunction with substances

and mixtures classified as hazardous by the Annex I part 2-5 of the

CLP regulation (EC 1272/2008), and identified with hazard picto-

grams GHS01-GHS06 and GHS08.

None of the products manufactured by SKF can be used in con-

junction with gases, liquefied gases, pressurized gases in solution

and fluids with a vapor pressure exceeding normal atmospheric

pressure (1013 mbar) by more than 0.5 bar at their maximum per-

missible temperature.

Unless otherwise noted, products of SKF must not be used in

conjunction with explosive atmospheres according to the ATEX-Di-

rective 2014/34/EU.

1.2 Authorized personnel

The products described in the installation instructions may only be

installed, operated, maintained, and repaired by qualified experts.

Qualified experts are persons who have been trained, instructed,

and familiarized with the end product into which the described prod-

uct is installed.

These persons are considered capable of such tasks due to their

education, training, and experience with valid standards, conditions,

accident prevention regulations in effect, and installation conditions.

They should be able to carry out the required tasks and to recognize

– and thus avoid – any dangers that might otherwise occur.

A definition of what constitutes a qualified person and who are

unqualified persons are stipulated in DIN VDE 0105 and IEC 364.

1.3 Danger relating to electric current

The electrical connection for the described product may only be es-

tablished by qualified, instructed persons who have been authorized

by the operator or owner to carry out this task. If the product is im-

properly connected, substantial material or personal damage my be

the consequence.

1.4 Danger relating to system pressure

3