3B-490033NU – 10/19

BONNET GRANDE CUISINE

Rue des Frères Lumière - Z.I Mitry Compans

77292 MITRY MORY Cedex

CONSEILS PRATIQUES D’UTILISATION / PRACTICAL HINTS FOR USE / PRAKTISCHE ANWENDUNGSTIPPS

/ CONSEJO PRÁCTICO DE UTILIZACIÓN

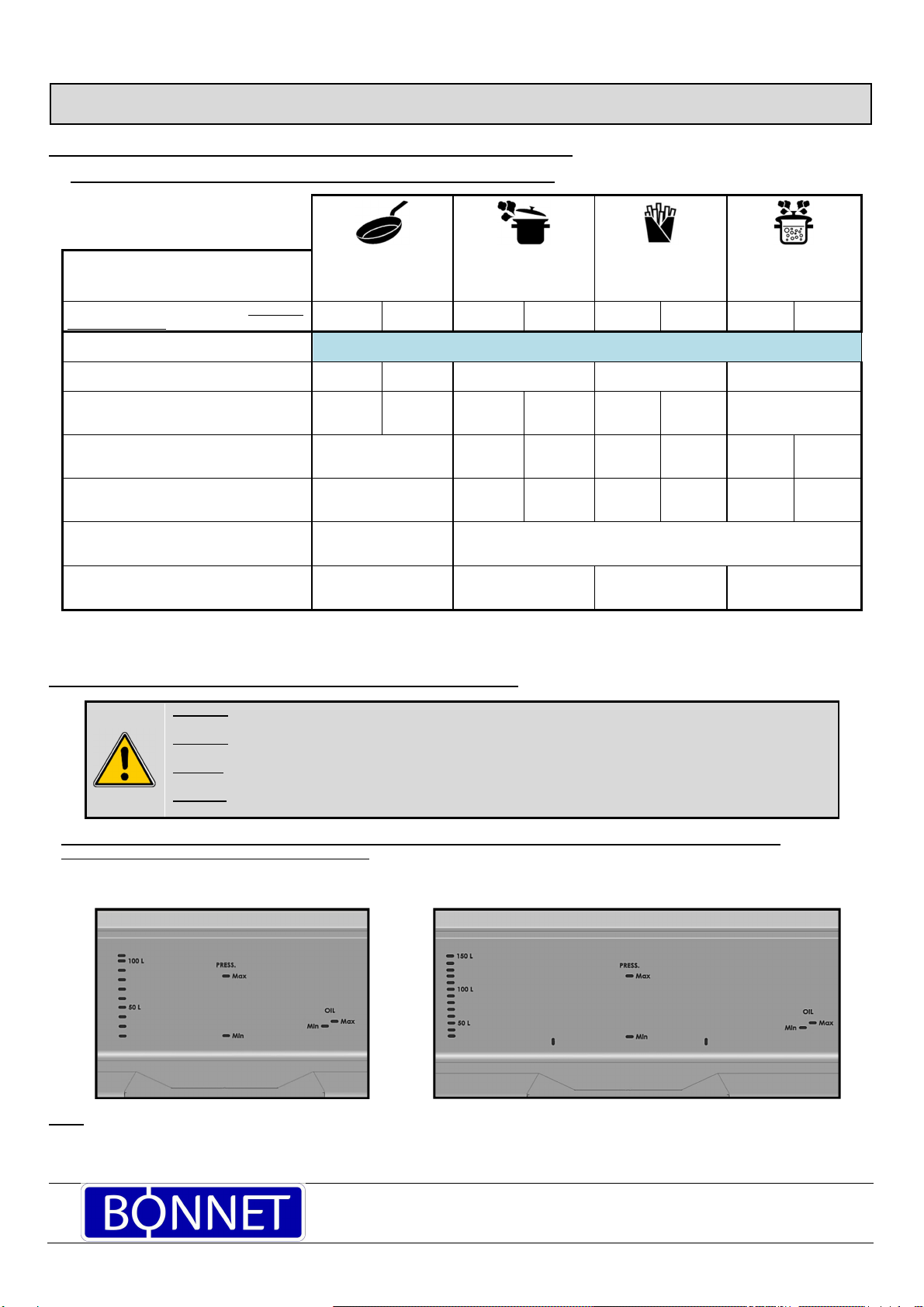

LIMITES D'UTILISATION / USABLE LIMITS / BESCHICKUNGSMENGEN / LÍMITES DE USO

Capacité cuve: / Tank capacity: / Fassungsvermögen Becken: / Capacidad de la cubeta:

Mode / Mode / Betriebsart / Modo

Bratt pan / Plancha

Bratpfanne / Grillplatte

Boiling / braising pan

Kochkessel / Braisière

Friteuse / Fryer /

Fritteuse / Freidora Pression / Pressure

/ Druck / Presión

Capacité cuves / Tank capacity /Fassungs-

vermögen Becken / Capacidad de las cubetas

100L 150L 100L 150L 100L 150L 100L 150L

Dimensions cuve (mm)* / Tank dimensions

/ Beckenabmessungen / Medidas cubeta 693 x 629 x 270 (100L) / 993 x 629 x 270 (150L)

Surface utile (dm

) / Usable surface (dm

) /

Nutzfläche (dm2) / Superficie útil (dm2)44 62 - - -

Capacité nominale (litres) / Nominal

capacity (litres) / Nennfassung (Liter) /

Capacidad nominal (litros) 105 151 105 151 35** 50** -

Capacité minimum (litres) / Minimum

capacity (litres) / Fassungsvermögen min

(Liter) / Capacidad mínima (litros) - 20 30 30** 43** 20 30

Capacité maximum (litres) / Maximum

capacity (litres) / Fassungsvermögen max

(Liter) / Capacidad máxima (litros) - 105 151 35** 50** 84 120

Dimensions panier GN1/1* / GN1/1 Basket

dimensions / Korbabmessungen GN1/1 /

Medidas cesta GN1/1 - 306 x 550 x 151

Capacité panier GN1/1 (kg)*** / GN1/1

Basket capacity /Korbfassungsvermögen

GN1/1 / Capacidad de la cesta GN1/1 - 15 / 8 2.5 / 2.5 15 / -

* Largeur x Avancée x Hauteur / Width x Depth x Height / Breite x Tiefe x Höhe / Anchura x Longitud x Altura

** Volume d’huile / Volume of oil / Ölmenge / Volumen de aceite

*** Sans / Avec utilisation du bras de relevage paniers / Without / With use of the basket lift arm / Ohne / Mit Nutzung des Korbhebearms / Con / Sin usar el brazo

elevador de la cesta

LIMITE DE CHARGE / LOAD LIMITS / BELADUNGSGRENZE / LÍMITE DE CARGA

Pour votre sécurité et celle de votre appareil, veuillez toujours à respecter les volumes de remplissage

minimum, nominal et maximum indiqués sur la paroi de la cuve.

Attention: For your safety and that of your equipment, always respect the minimum, nominal and maximum fill levels

indicated on the rear of the well.

Achtung: Beachten Sie bitte zu Ihrer eigenen Sicherheit und der Ihres Geräts immer die an der Beckenwand

angegebenen Mindest-, Nenn- und Maximalfüllmengen.

Atención: Para su seguridad y la de su aparato, respete siempre los volúmenes de llenado mínimo, nominal y máximo

que se muestran en la pared de la cubeta.

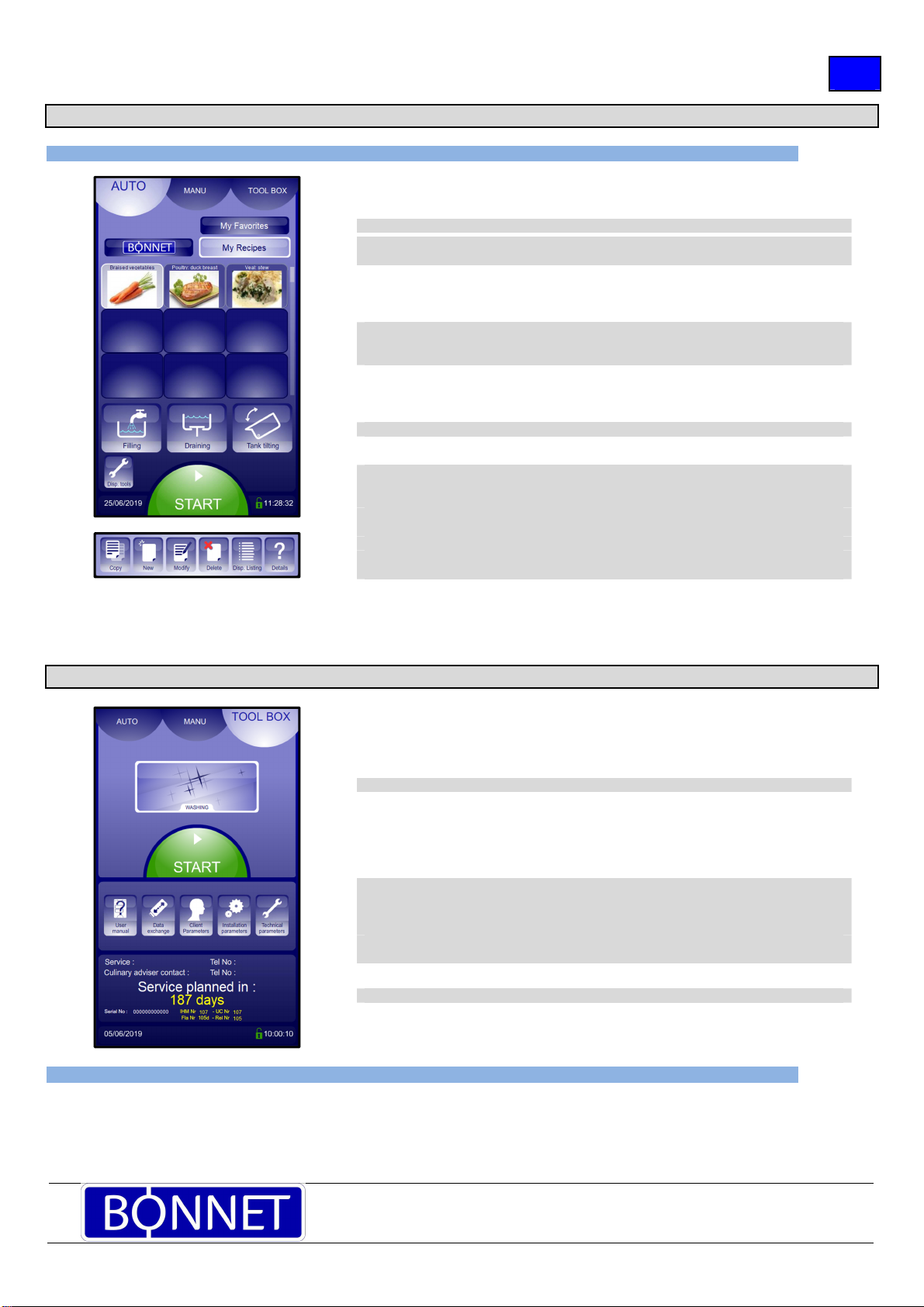

Correspondance graduation (en litres) des cuves / Corresponding graduations in the tanks / Skaleneinteilung (in Liter) der Becken /

Correspondencia graduación (en litros) de los depósitos

Braisière 100 litres / 100 litre braising pan

/ Braisière 100 liter / Cacerola 100 litros Braisière 150 litres / 150 litre braising pan /

Braisière 150 liter / Cacerola 150 litros

NOTA: Le non-respect de ces consignes engendrera des problèmes dont le constructeur ne pourra être tenu pour responsable. / Failure to respect

this advice could result in problems for which the manufacturer cannot be held responsible. / Falls diese Anweisungen nicht beachtet werden,

können Probleme entstehen, für die der Hersteller nicht haftbar gemacht werden kann / Si no respeta estas indicaciones, dará lugar a

problemas de los que no se podrá responsabilizar al fabricante.