3

Paint Sprayer Safety Warnings

1. INJECTION HAZARD! Although this paint gun is airless, it sll puts out paint at a very high pressure. Through improper use, paint can be injected through a

person’s skin, leading to serious injury, possibly amputaon. If paint is accidentally injected into someone’s skin, contact a doctor immediately. Do not treat

an injecon injury as a simple cut. Injecon can lead to amputaon and requires immediate surgical treatment.

2. Do not point your sprayer at anyone, including yourself. Do not place your hand in front of Spray Gun’s nozzle or aempt to deect paint s pray with your

hand during use. Gloves and clothing don’t oer adequate protecon from toxic paints, sealers, water-proofers, or stains.

3. Do not come into contact with a uid stream created by a leak in the paint hose.

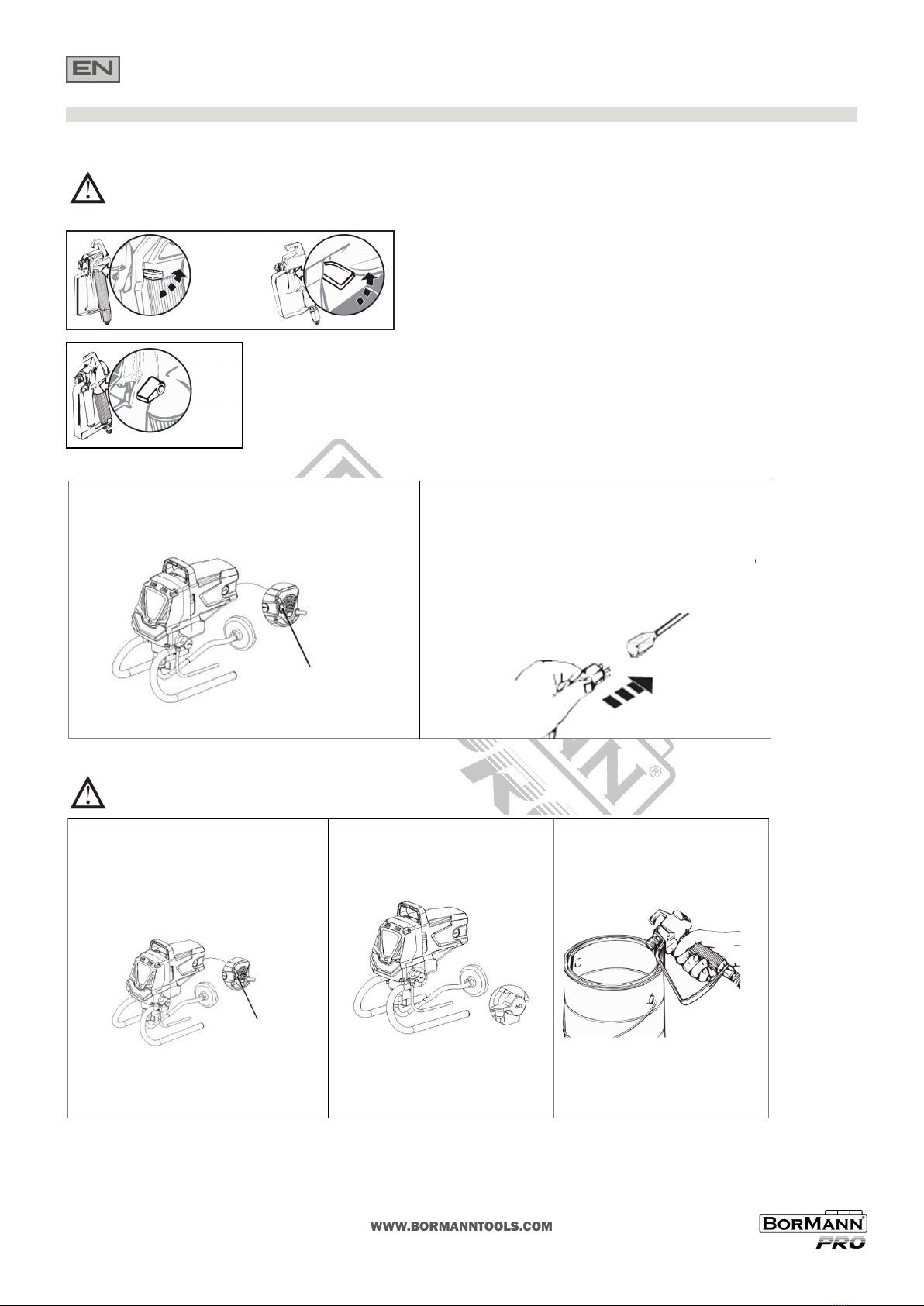

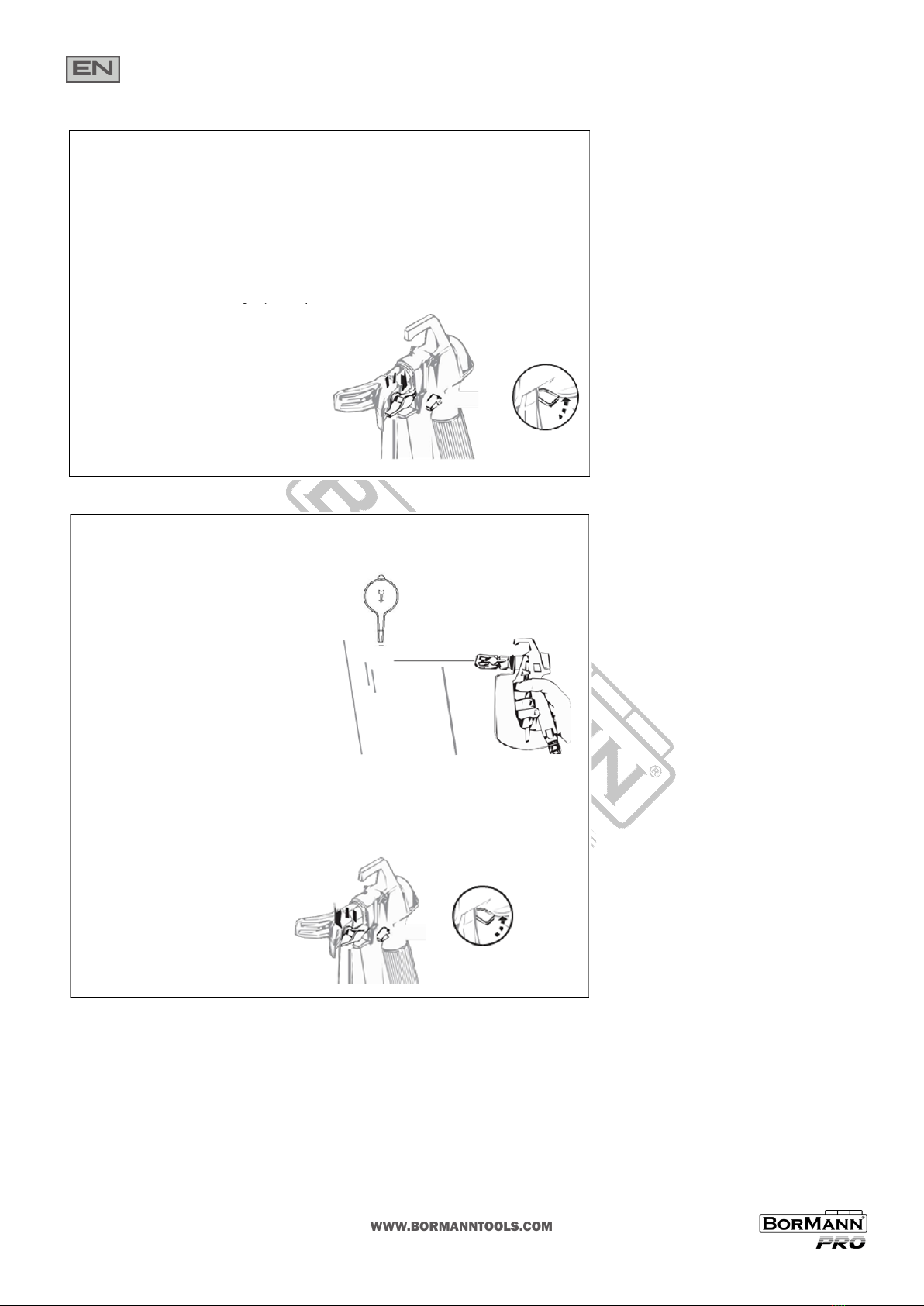

4. Engage the Spray Gun’s trigger lock when not spraying.

5. Do not leave Paint Sprayer pressurized while unaended.

6. Do not clean Spray Gun p while it is s ll connected to paint hose.

7. Keep the trigger and the electrical cord plug clean and paint-free.

8. Do not run Paint Sprayer while empty. Damage to the unit may occur.

9. Do not use Paint Sprayer to spray asbestos, metallic paints, glazes, red lead, cement, ground chalk, abrasive grainy paints containing lime, or bleach. These

will damage the spray gun and void the warranty.

10. Do not spray ammable materials in vicinity of open ame or near ignion sources. Motors, electrical equipment, and controls can cause electrical arcs

that will ignite a ammable gas or vapor. Do not store ammable liquids or gases in vicinity of this unit.

11. Keep re-exnguishing equipment present and in good-working order.

12. Keep pump away from spray area to avoid contact with solvents and paint fumes.

13. Use Paint Sprayer with water-based or mineral spirit-type materials only.

14. Do NOT use bleach, low-ash naphthalene, acetone alcohol or toluene when cleaning Paint Sprayer equipment.

15. Do NOT use solvents with ash points less than 70° F (21° C) to clean equipment. These may cause an explosion. Examples of acceptable cleaning solvents

are water, mineral spirits and lacquer thinner. Note that some of these solvents may be inappropriate for certain kinds of paint; follow the paint supplier’s

3. Personal safety

a. Stay alert. Watch what you are doing and use common sense when operang the sprayer. Do not use the sprayer while red or under the inuence of drugs,

alcohol, or medicaon. A moment of inaenon while operang the sprayer increases the risk of injury to persons.

b. Dress properly. Do not wear loose clothing or jewellery. Contain long hair. Keep hair, clothing, and gloves away from moving parts. Loose clothes, jewellery,

or long hair increases the risk of injury to persons as a result of being caught in moving parts.

c. Avoid unintenonal starng. Be sure the trigger is o before connecng to the power supply. Do not carry the sprayer with your nger on the trigger or

connect the sprayer to the power supply with the trigger on.

d. Do not overreach. Keep proper foong and balance at all mes. Proper foong and balance enables beer control of the sprayer in unexpected situaons.

e. Use safety equipment. Wear ANSI-approved safety goggles, a NIOSH-approved respirator, heavy-duty work gloves and non-skid

safety shoes when priming, painng, cleaning, or servicing.

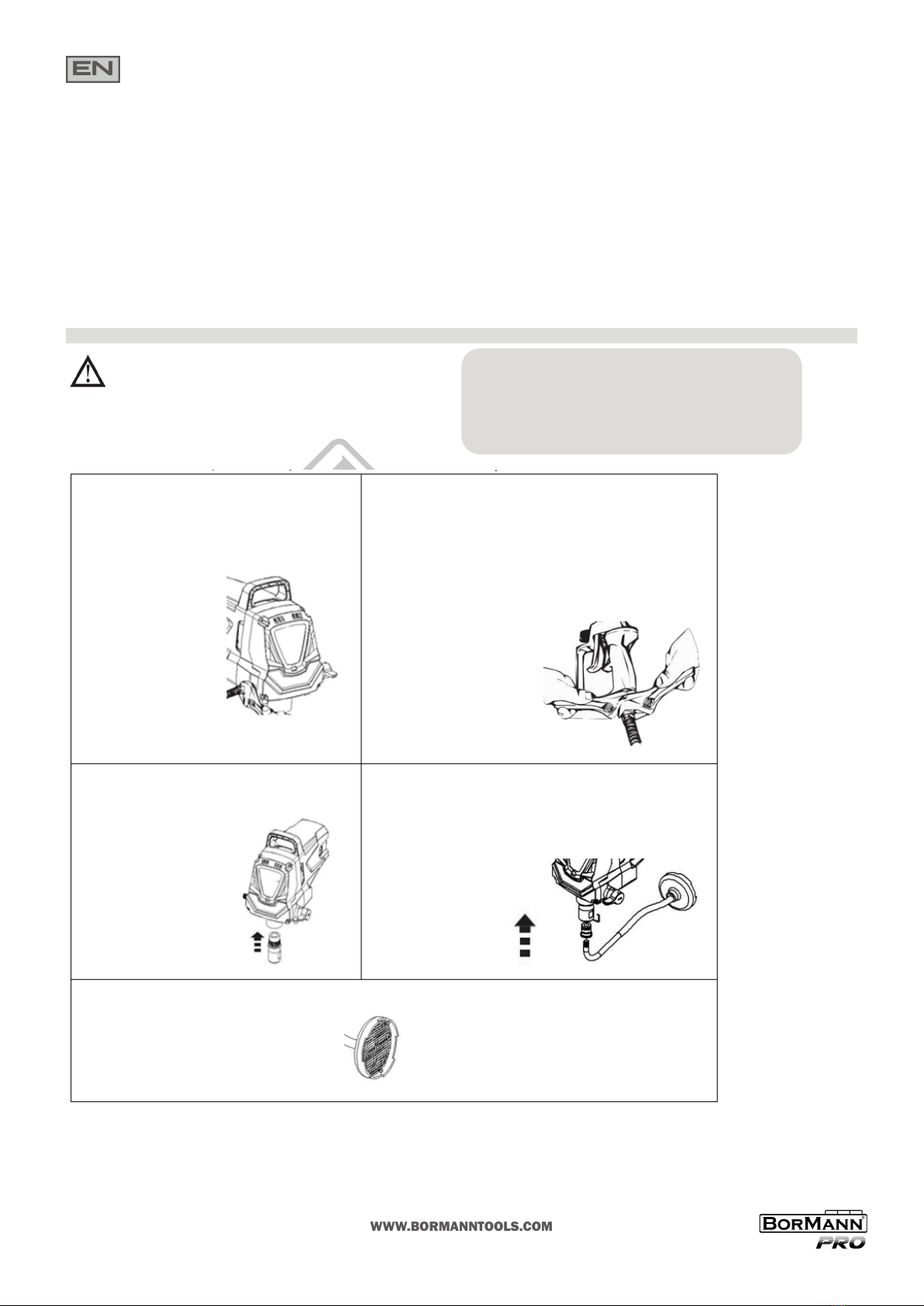

4. Sprayer use and care

a. Do not force the sprayer. Use the correct sprayer for your applicaon.

The correct sprayer will do the job beer and safer at the rate for which it was designed.

b. Do not use the sprayer if the switch does not turn it on and o. Any sprayer that cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source before making any adjustments, c hanging accessories, or storing sprayers. Such prevenve safety measures

reduce the risk of starng the sprayer accidentally.

d. Store idle sprayers out of the reach of children and do not allow persons unfamiliar with the sprayer or these instrucons to operate the sprayer. Sprayers

are dangerous in the hands of untrained users.

e. Maintain the sprayer. Check for misalignment or binding of moving parts, breakage of parts and any other condion that may aect the s prayer’s operaon.

If damaged, have the s prayer repaired before use. Many accidents are caused by poorly maintained sprayers.

f. Use the sprayer and accessories in accordance with these instrucons, taking into account the working condions and the work

to be performed. Use of the sprayer for operaons dierent from those intended could result in a hazardous situaon.

5. Service

a. Have your sprayer serviced by a qualied repair person using only idencal replacement parts. This will ensure that the safety of the sprayer is maintained.

recommendaons. Contact your supplier to request a Material Safety Data Sheet (MSDS).

16. Follow the material and solvent manufacturer’s safety precauons and warnings.

17. Keep paint hose away from sharp objects. Bursng hoses may cause injury. Examine hoses regularly and replace if damaged.

18. When ushing Paint Sprayer system, use lowest possible pressure seng.

19. All hoses and spray gun accessories used with Paint Sprayer must be pressure rated at or above 3000 PSI.

20. The Paint Sprayer must be plugged into an outlet that is grounded in accordance with all local codes and ordinances.

21. Use cauon while spraying on windy days.

22. Do not use Paint Sprayer without the Spray Gun’s nozzle guard in place.

23. Paint Sprayer’s housing may become hot during use. Do not touch housing unl it has completely cooled.

24. Remove Spray Tip or turn to cleaning posion BEFORE cleaning or ushing Paint Sprayer system.

25. Do not use pliers to ghten or loosen high pressure connecons.

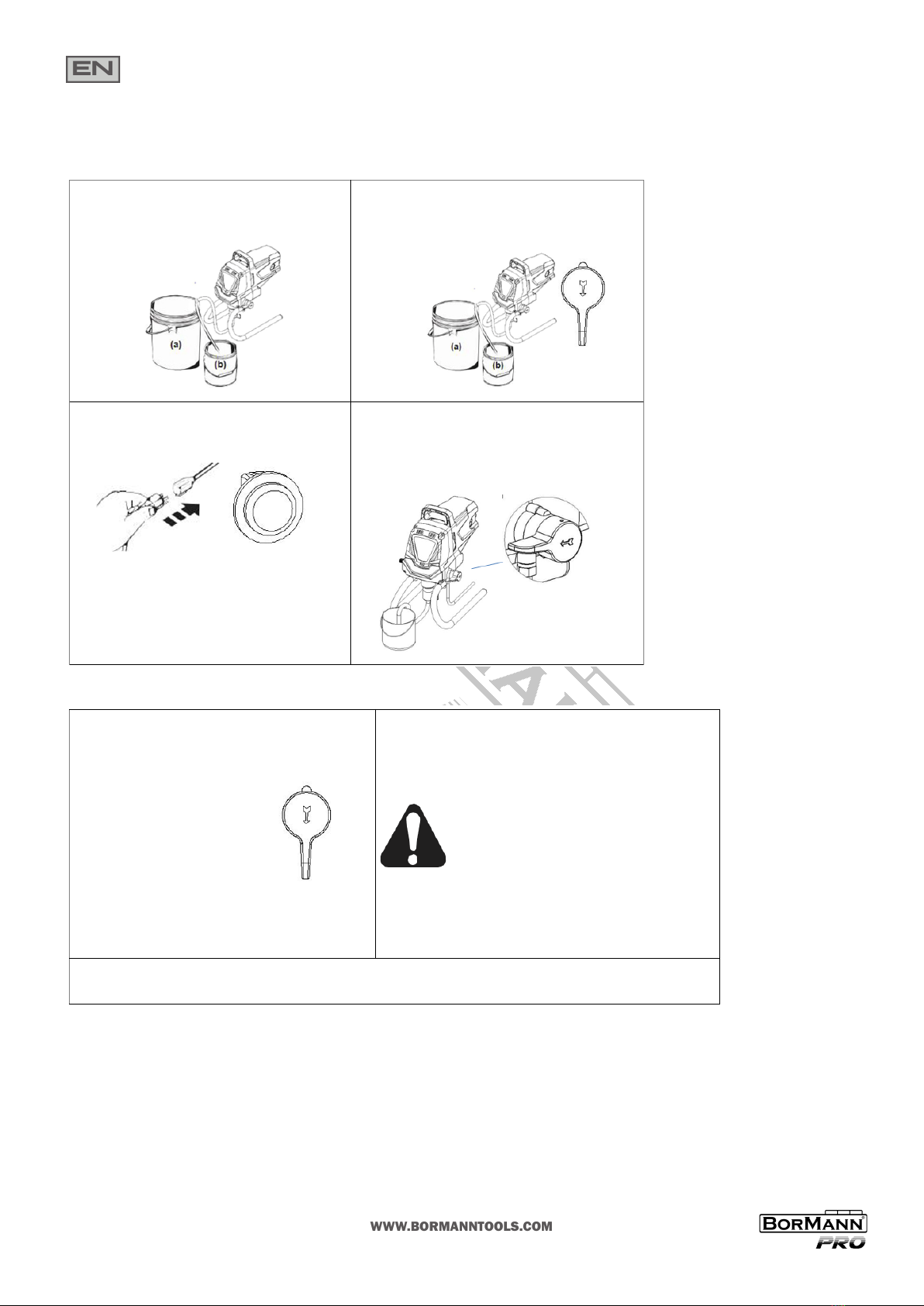

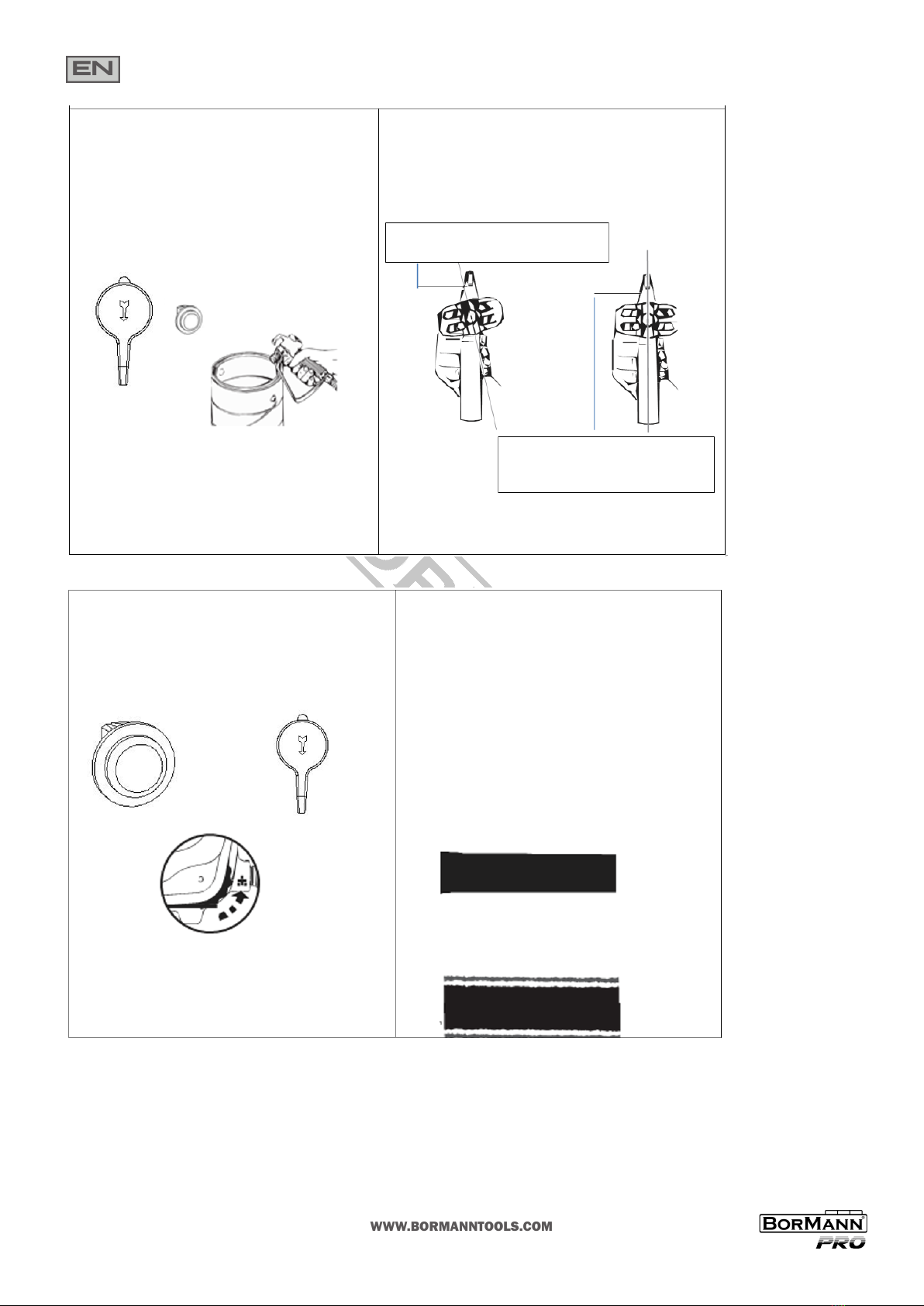

26. Sparks from improper grounding can ignite fumes! Follow all local regulaons regarding the use of uid supply containers and solvent pails used with

ushing the Paint Sprayer. Use only conducve metal pails placed on a grounded (concrete) surface. Do not place pails on nonconducve surfaces (such as

cardboard or paper). Ground all metal pails by clamping one end of a ground wire to the pail and the other end to a grounded structure (such as a nearby

pipe). Maintain grounding, even when ushing or relieving pressure from Paint

Sprayer into metal pail. The force of the spray can knock a metal pail over, so hold down the metal pail and keep the metal part of the spray gun set against

the grounded metal pail when pressing the spray gun trigger.

27. Maintain labels and nameplates on the sprayer. These carry important safety informaon. If unreadable or missing, contact your supplier for a replace-

ment.

28. Avoid unintenonal starng. Prepare to begin work before turning on the sprayer.

29. This product is not a toy. Keep it out of reach of children.

30. People with pacemakers should consult their physician(s) before use. Electromagnec elds in close proximity to heart pacemaker could cause pacemak-