1Introduction

The Data Logger / Streamer application for Cross-Domain Development Kit XDK110 is intended to extract raw data from

the XDK with the highest performance achievable with the build-in sensors, giving the user the ability to acquire reliable,

highly accurate data for further analysis. The data are stored locally on the SD card within the device. Alternatively, the data

can also be sent to a network computer via WLAN.

1.1 Key features of the XDL120 DataLogger/ Streamer

Easy data acquisition from on-board sensors of XDK (except acoustic noise) with high data rates

Customizable: Sensor selection and configuration via xml file, no programming needed

Saves data locally on SD card (logging mode)

Transmits data continuously via WLAN to a UDP socket (streaming mode) (Enterprise WPA2 option available)

Auto save feature with configurable saving frequency

MessagePack format for integration in third-party applications

Time-equidistant sampling with global time synchronization support with SNTP over WLAN

Simply pressing a button starts and stops data logging/streaming

1.2 Components of XDL120 shipment

The following components are part of the XDL120:

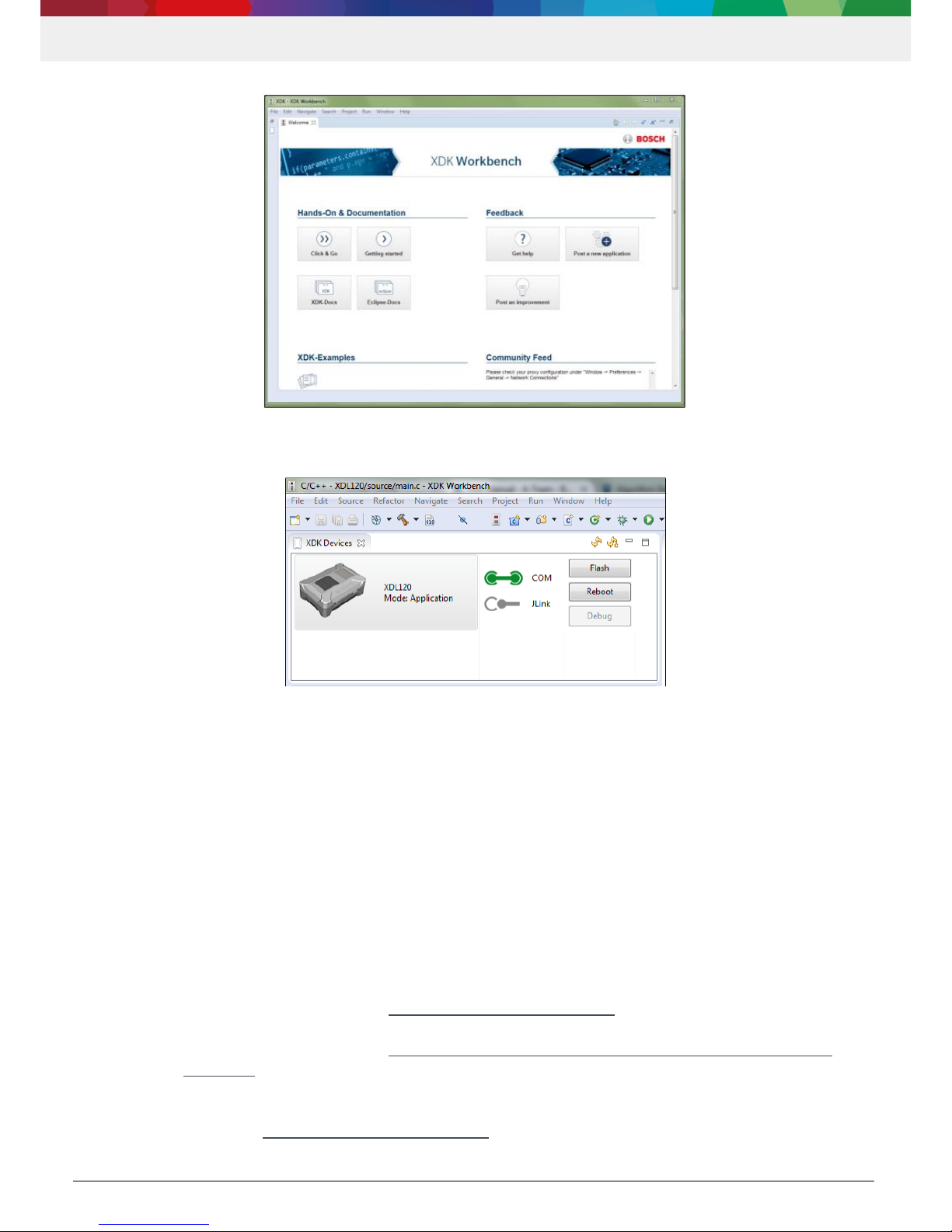

Binary files (full version):

oXDL120_Rev1.bin : for XDK with bootloader <v1.0

oXDL120_Rev2.bin : for XDK with bootloader ≥v1.0

Binary files (trial version):

oXDL120_trial_Rev1.bin : for XDK with bootloader <v1.0

oXDL120_trial_Rev2.bin : for XDK with bootloader ≥v1.0

Datalogger.exe (alternative: datalogger.py python script for systems with python3 environment available)

config.XML file

wlan.TXT file

XDL120_tolerance_calculation.xls

EULA / Licence text (PDF)

User manual (this document)