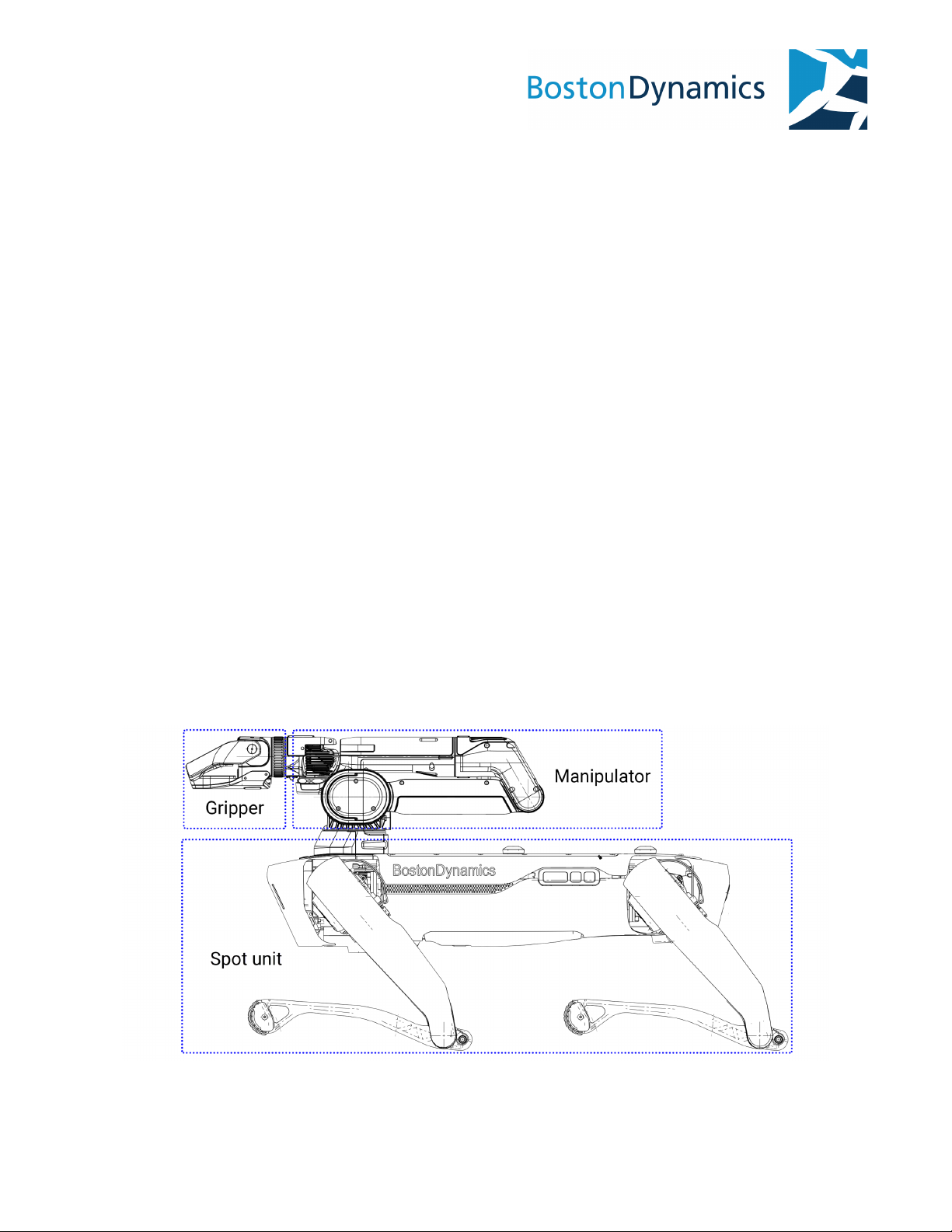

Spot + Spot Arm Information for Use v1.0

1 Introduction

This document contains critical safety information for Spot Arm.

Responsible use of the Spot Arm is crucial to prevent dangerous conditions for operators

and others nearby. Make sure to read, understand and comply with this document to

lessen the risk of injuries or damage to the robot or other property.

Please read the entire document before using the Spot Arm and keep the document in a

readily accessible location afterwards.

Additional information, including complete documentation on the Spot robot and Spot

Dock is available on the Boston Dynamics Support Center.

1.1 Manufacturer information

Spot and the Spot Arm are manufactured by:

Boston Dynamics, Inc.

200 Smith Street

Waltham, MA 02451

USA

1.2 Definition of a Spot User

In the scope of the present document, a “User” is the entity that uses Spot Arm for the

intended use and is responsible for the personnel associated with operation of the robot.

Users are subject to workplace safety regulations and are active counterparts of the

manufacturer in implementing residual risk reduction measures.

1.3 Definition of a Spot Operator

In the scope of the present document, an “Operator” is any person operating,

maintaining, cleaning, or troubleshooting Spot Arm under the responsibility of a User,

including person(s) who can be reasonably expected to be near Spot Arm, even if they are

not directly operating the robot. Operators must be trained in the proper use of Spot Arm.