9e1075 Page 2

CONTENTS

1. PREFACE

1.1 MANUFACTURER’S ADRESS ......................................................................................................................................................... 3

1.2 CUSTOMER SERVICE........................................................................................................................................................................ 3

1.3 GUIDELINES, LAWS, STANDARDS............................................................................................................................................... 3

1.3.1 DECLARATION OF CONFORMITY ............................................................................................................................................... 4

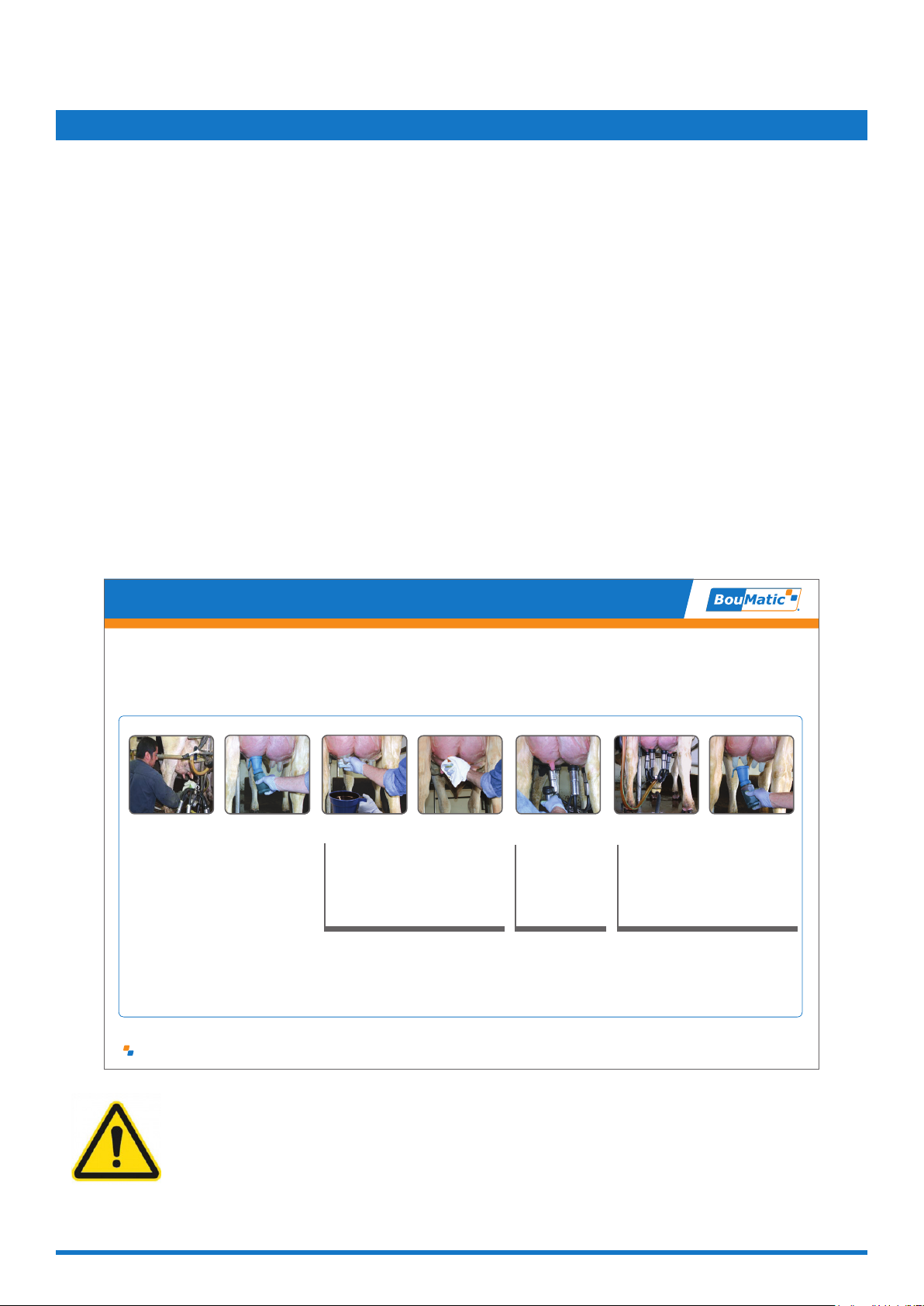

1.4 SUCCESSFUL MILKING.................................................................................................................................................................... 5

2. SAFETY

2.1 OWNER’S DUTY OF CARE.............................................................................................................................................................. 6

2.2 BASIC SAFETY INSTRUCTIONS.................................................................................................................................................... 7

2.3 PERSONNEL QUALIFICATION....................................................................................................................................................... 8

2.4 PROTECTIVE EQUIPMENT.............................................................................................................................................................. 9

2.5 SAFETY SIGNS, STICKERS AND LABELS ................................................................................................................................... 9

2.6 PACKAGING MATERIALS ................................................................................................................................................................ 9

2.7 CORRECT APPLICATION................................................................................................................................................................. 9

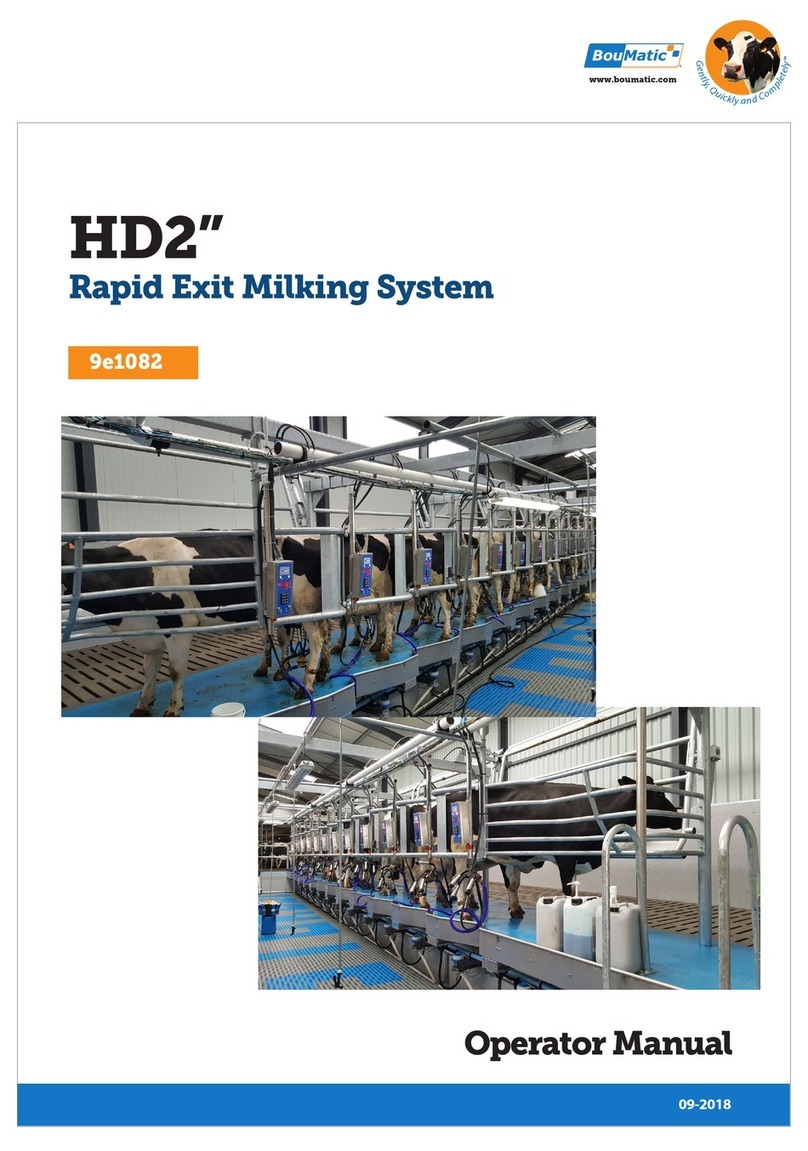

3. DESCRIPTION

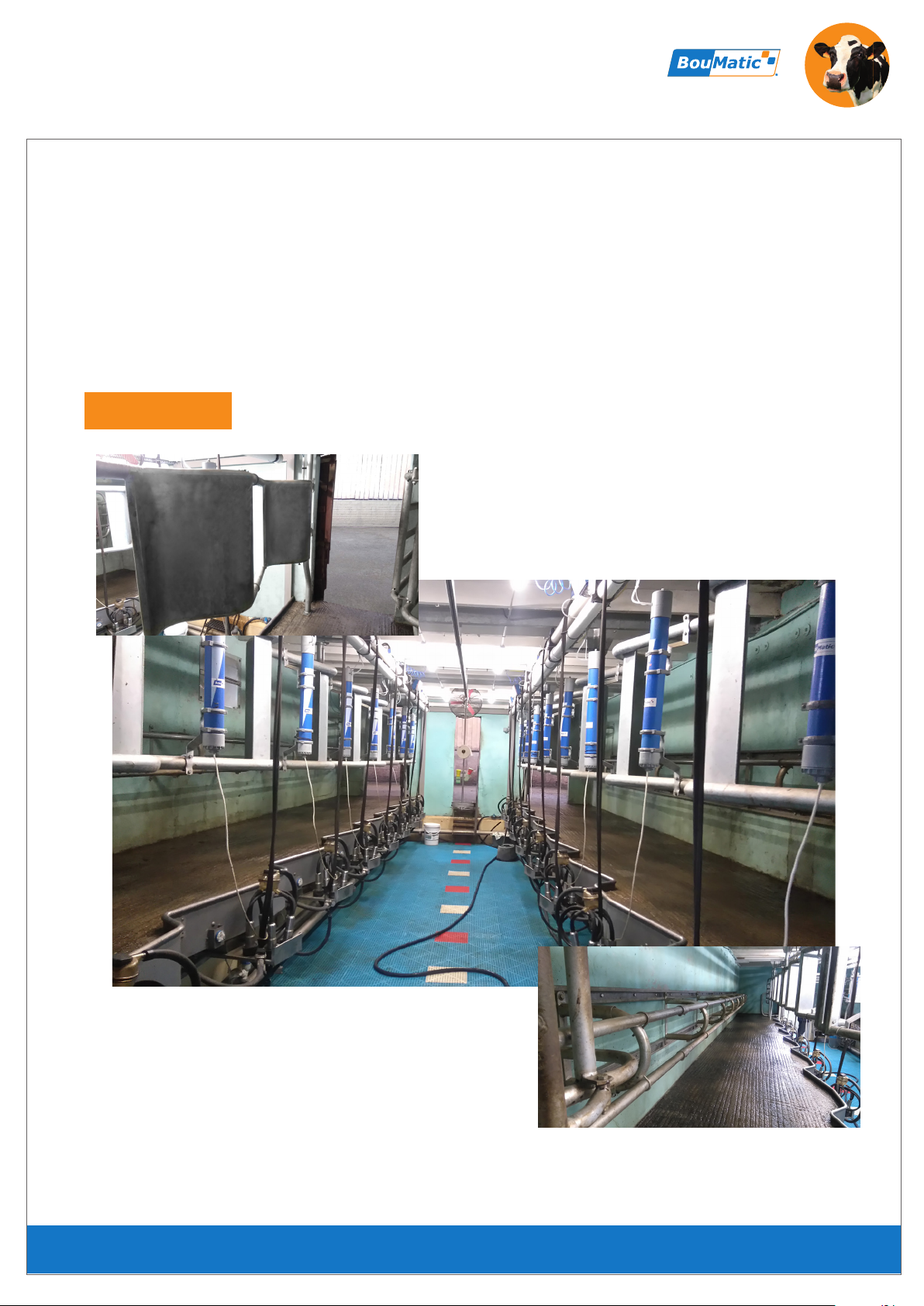

3.1 INSTALLATION CONDITIONS......................................................................................................................................................11

3.2 NOISE LEVEL .....................................................................................................................................................................................11

3.3 DELIVERY............................................................................................................................................................................................12

3.4 STORAGE............................................................................................................................................................................................12

3.5 RECOMMENDATIONS....................................................................................................................................................................13

3.6 SYMBOLS ...........................................................................................................................................................................................13

4. CONTROL AND OPERATING UNIT

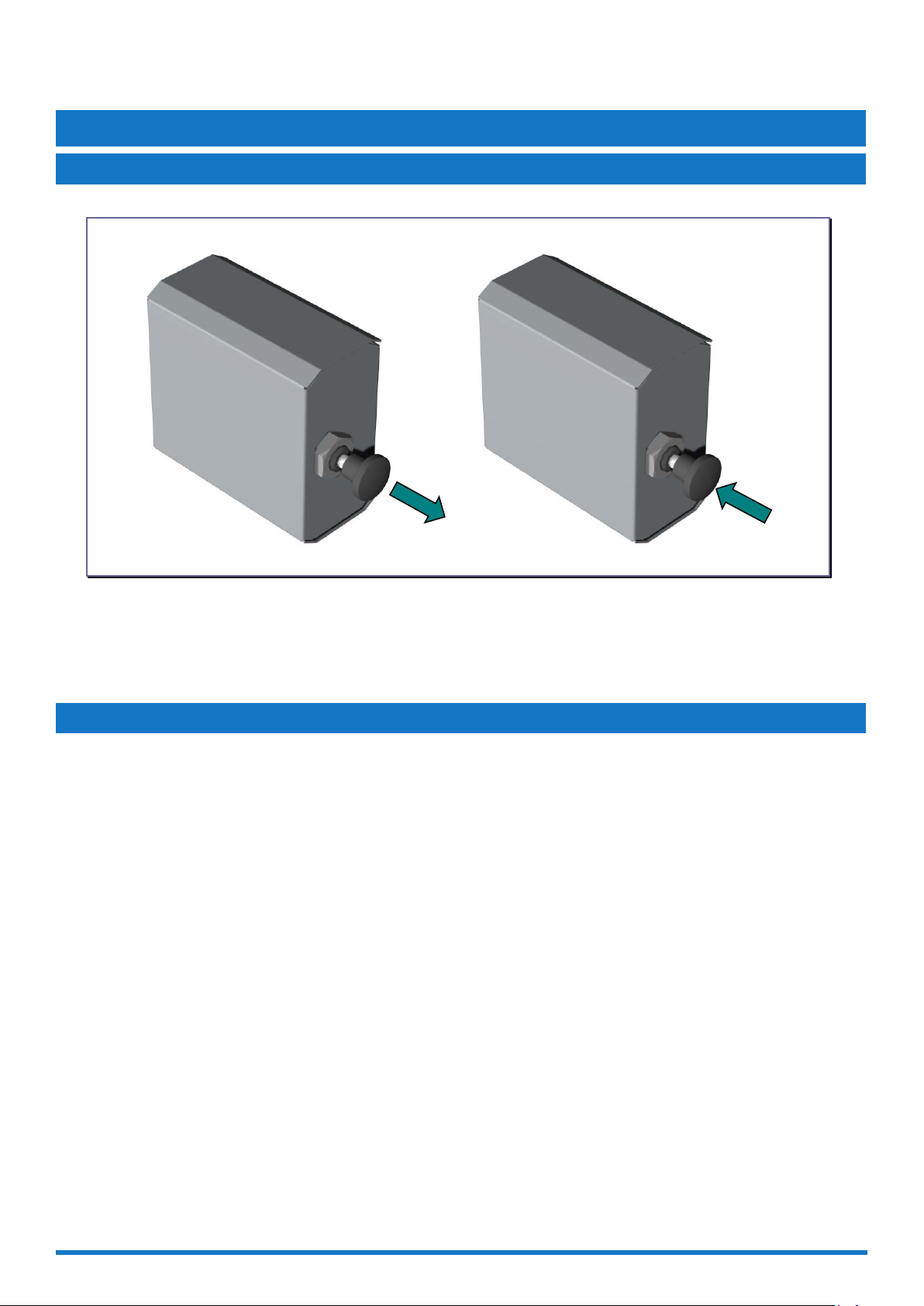

4.1 CONTROL UNIT................................................................................................................................................................................14

4.2 OPERATION OF THE HD2.............................................................................................................................................................14

5. CLEANING

5. CLEANING..........................................................................................................................................................................................15

6. MAINTENANCE

6. MAINTENANCE................................................................................................................................................................................15

7. DECOMMISSIONING

7.1 SPECIAL PERSONNEL QUALIFICATION REQUIRED FOR DECOMMISSIONING .......................................................19

7.2 SAFETY INSTRUCTIONS FOR DECOMMISSIONING...........................................................................................................19

7.3 SPECIAL DANGERS INVOLVED IN DECOMMISSIONING..................................................................................................19

7.4 FINAL DECOMMISSIONING / DISPOSAL................................................................................................................................19