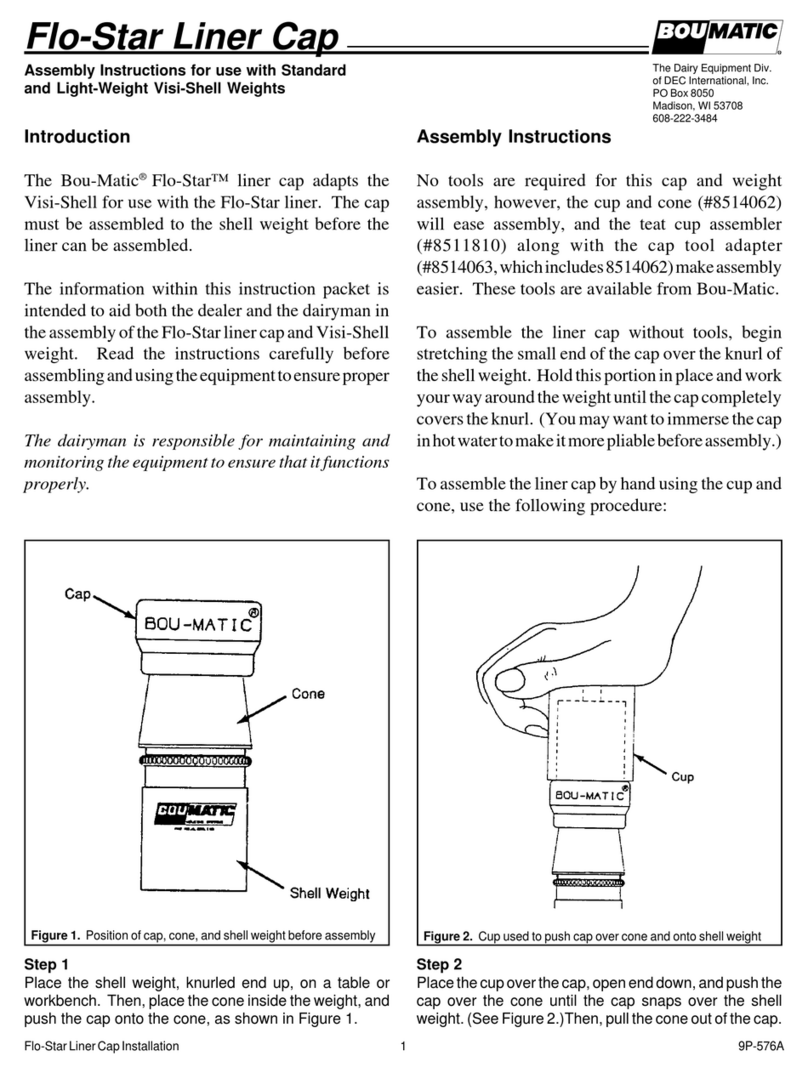

9e1063 Page 2

CONTENTS

1. PREFACE

1.1 MANUFACTURER’S ADDRESS........................................................................................................................................................... 4

1.2 CUSTOMER SERVICE ........................................................................................................................................................................... 4

1.3 GUIDELINES, LAWS, STANDARDS.................................................................................................................................................... 4

1.3.1 DECLARATION OF CONFORMITY ................................................................................................................................................... 5

1.4 SUCCESSFUL MILKING.................................................................................................................................................................... 6

2. SAFETY

2.1 OWNER’S DUTY OF CARE ............................................................................................................................................................. 7

2.2 BASIC SAFETY INSTRUCTIONS.................................................................................................................................................... 8

2.3 PERSONNEL QUALIFICATION....................................................................................................................................................... 9

2.4 PROTECTIVE EQUIPMENT............................................................................................................................................................10

2.5 SAFETY SIGNS, STICKERS AND LABELS .................................................................................................................................10

2.6 PACKAGING MATERIALS ..............................................................................................................................................................10

2.7 CORRECT APPLICATION...............................................................................................................................................................10

2.8 DELIVERY............................................................................................................................................................................................12

2.9 STORAGE ...........................................................................................................................................................................................12

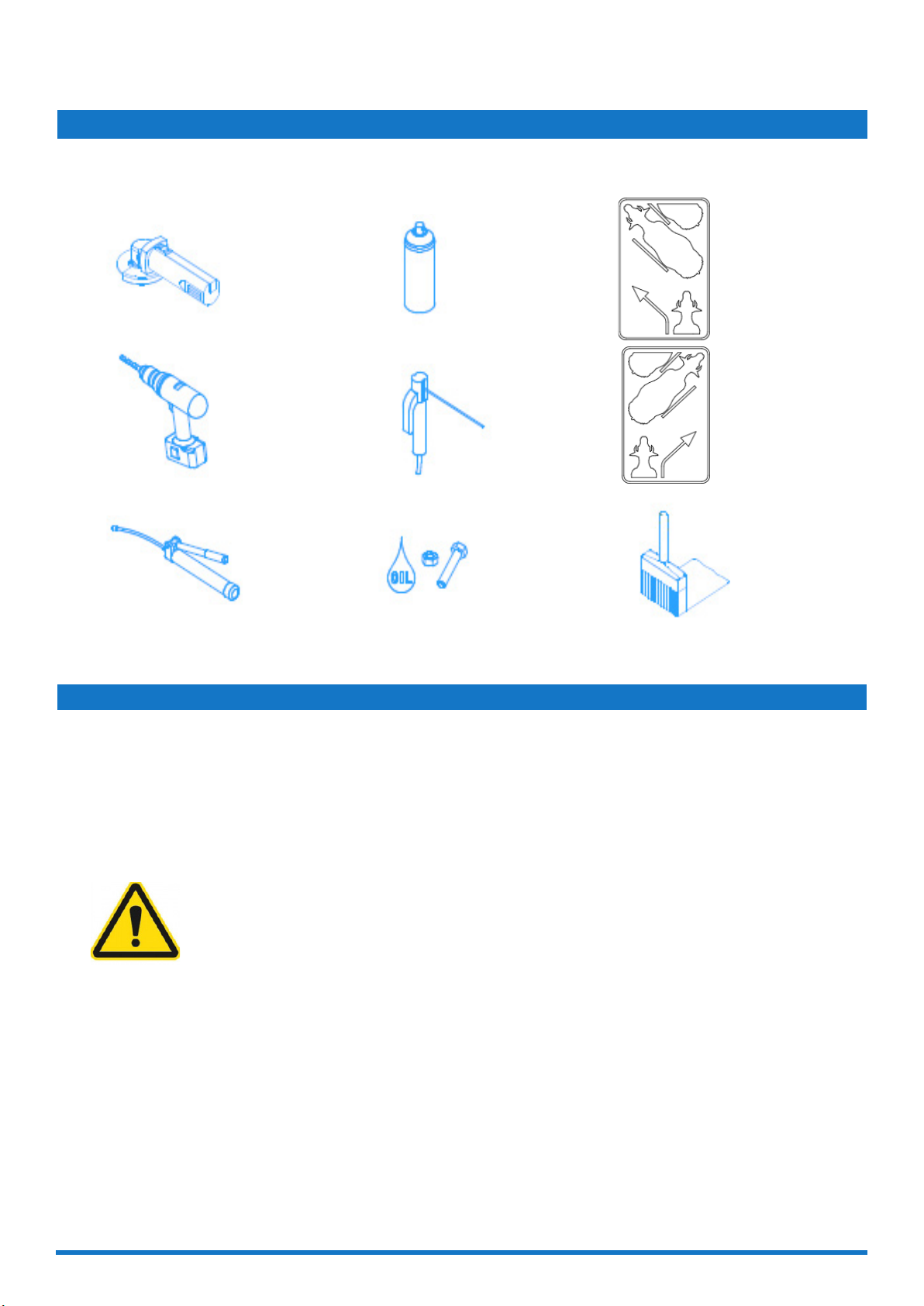

3. ASSEMBLY INSTRUCTIONS AND EXPLANATION OF SYMBOLS

3.1 ASSEMBLY INSTRUCTIONS ........................................................................................................................................................13

3.2 SYMBOLS ..........................................................................................................................................................................................14

3.3 RECOMMENDATIONS ...................................................................................................................................................................14

4. INSTALLATION

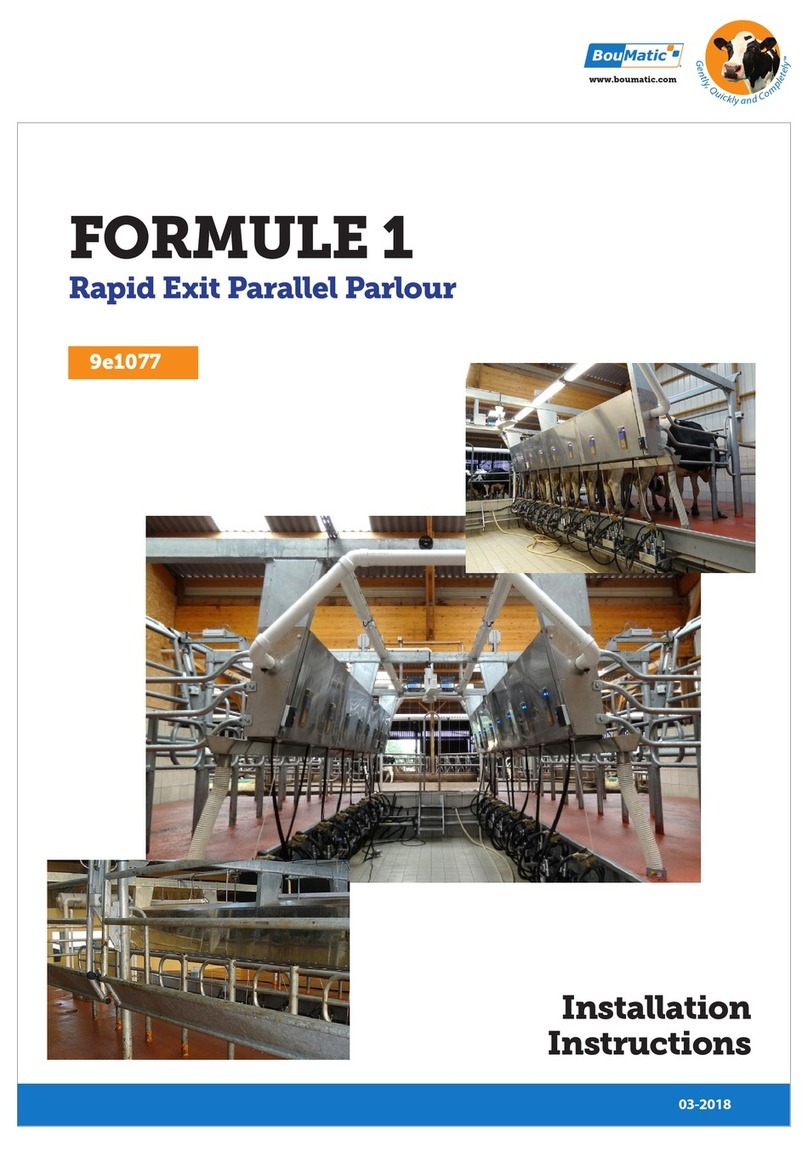

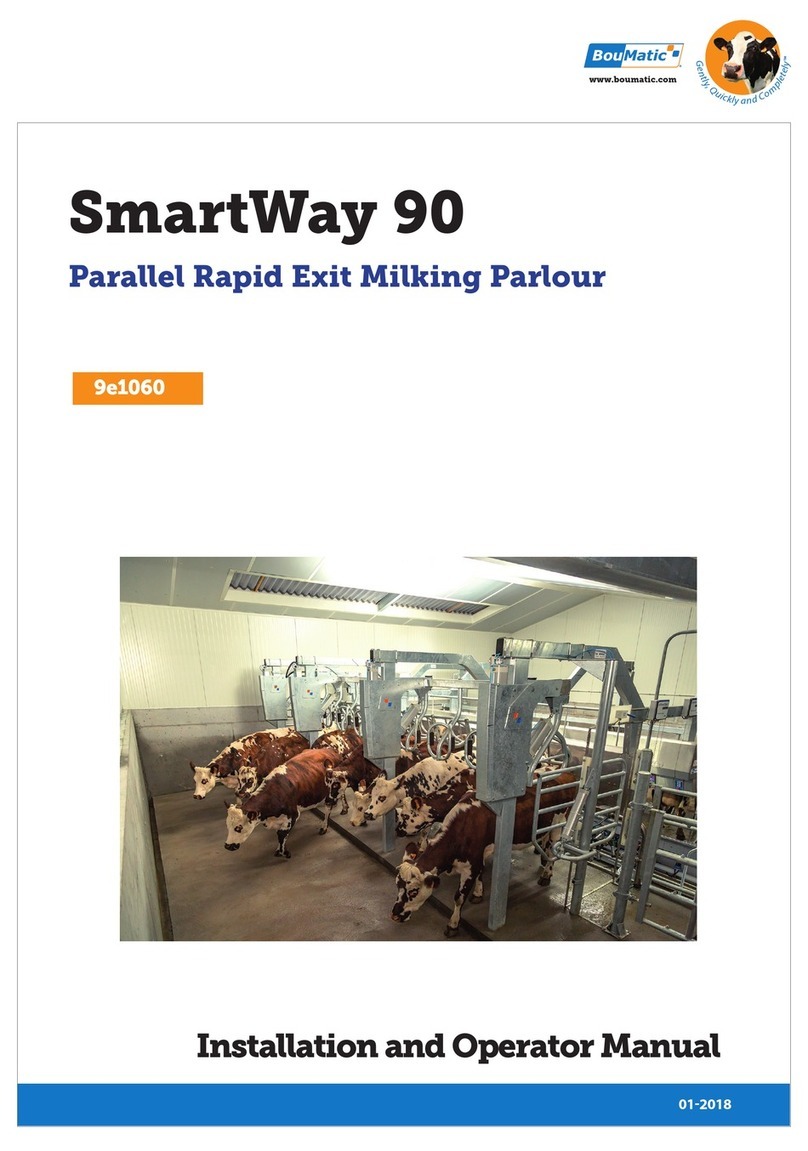

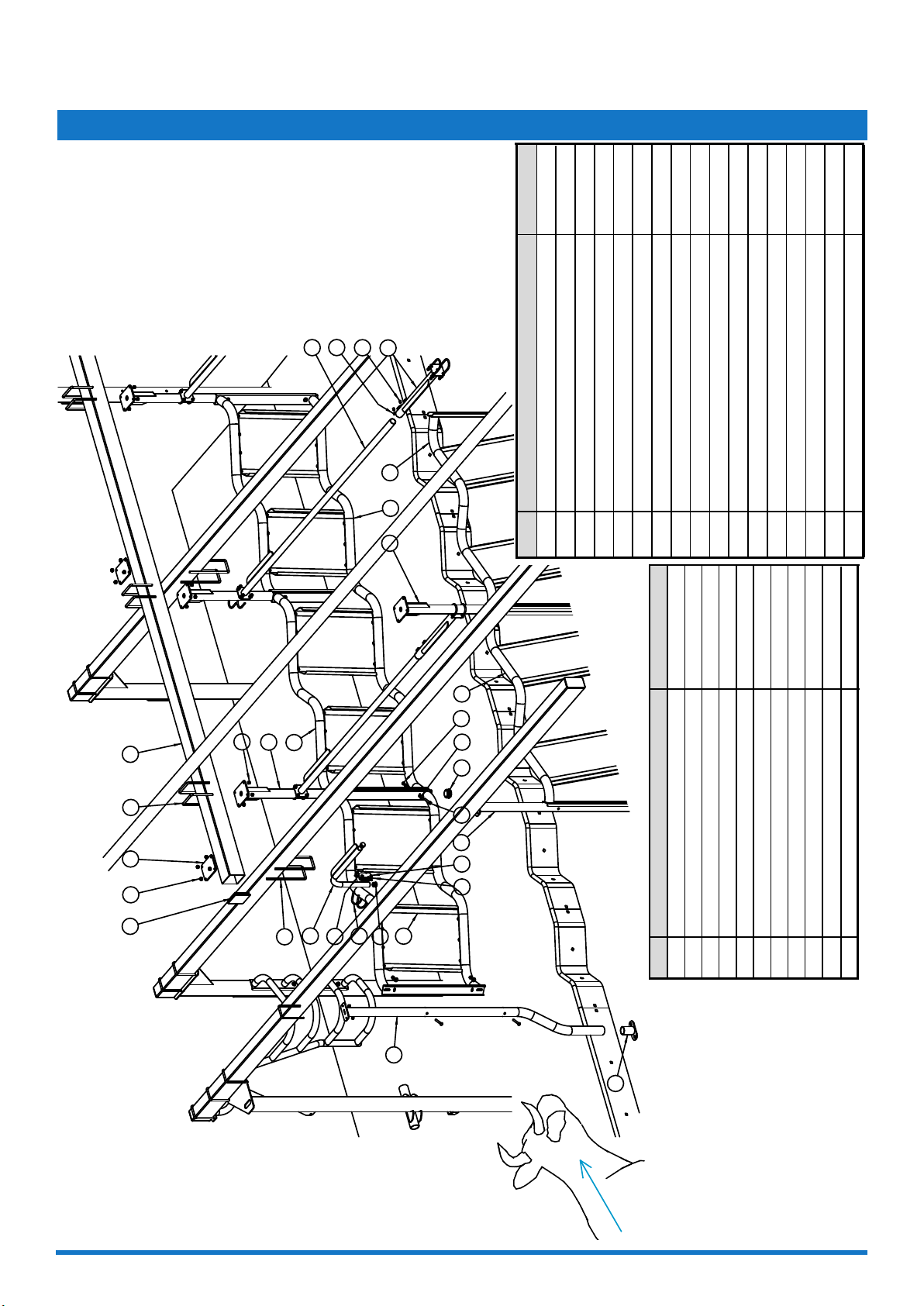

4.1 INDEXABLE MILKING PARLOR GT2 2X7 WITH INDEXING AND RAPID EXIT.............................................................15

4.2 INSTALLATION OF THE STRUCTURAL PARTS.........................................................................................................................................................................16

4.3 INSTALLATION OF THE GATE POST AND THE ENTRANCE BARRIER ...........................................................................17

4.4 BITUMEN PROTECTIVE COATING ............................................................................................................................................18

4.5 INSTALLATION OF THE RUMP RAIL .........................................................................................................................................19

4.6 INSTALLATION OF THE KNIFE GATE .......................................................................................................................................20

4.7 INSTALLATION OF THE END BARRIER.....................................................................................................................................21

4.8 INSTALLATION OF THE PNEUMATIC EXIT REEL .................................................................................................................22

4.9 INSTALLATION OF THE PNEUMATIC EXIT REEL DRIVE ....................................................................................................23

4.10 INSTALLATION OF THE PNEUMATICALLY ACTUATED LOCK..........................................................................................24

4.11 INSTALLATION OF THE INDEXING CYLINDER ....................................................................................................................25

4.12 OPTION: INSTALLATION OF THE SINUS CURBING ..........................................................................................................26

4.13 OPTION: INSTALLATION OF THE DETACHER CYLINDER BRACKET..............................................................................28

5. AUTOMATISATION, CONTROLLING, STARTUP AND FINAL TEST

5.1 USER CONTROLS.............................................................................................................................................................................29

5.2 INSTALLATION..................................................................................................................................................................................29

5.3 ELECTRIC WIRING RECOMMENDATION.................................................................................................................................30

5.4 END OFF STROKE ADJUSTMENT..............................................................................................................................................30

5.5 BUTTON BOX CONTROL ..............................................................................................................................................................30

5.6 CONTOL AND ADJUSTMENT OFF THE PHOTOCELL OPTION.....................................................................................30

5.7 TESTS ...................................................................................................................................................................................................31

5.8 ADJUSTING DURATION OF REEL IN HORIZONTAL REST POSITION ...........................................................................31

5.9 ADJUSTING INDEXING DELAY AFTER GATE CLOSURE 0 TO 10 SECONDS............................................................32

5.10 MAINTENANCE................................................................................................................................................................................32