Boumatic SmartWay 90 Setup guide

SmartWay 90

9e1037

Installation and Operator Manual

9e1060

Parallel Rapid Exit Milking Parlour

www.boumatic.com

G

e

n

t

l

y

,

Q

u

i

c

k

l

y

a

n

d

C

o

m

p

l

e

t

e

l

y

™

01-2018

Page 2

9e1060

4.17 ASSEMBLING THE FRONT RAIL JOINT CONNECTIONS ............................................................................................34

4.18 ASSEMBLING THE FRONT RAIL CROSS BEAM .............................................................................................................35

4.19 ASSEMBLING THE DIVIDER GATES ..................................................................................................................................36

4.20 ASSEMBLING THE STAYTUBE END STOP ......................................................................................................................37

4.21 ASSEMBLING THE UPPER CABINET SUPPORT ............................................................................................................38

4.22 ASSEMBLING THE LOWER CABINET SUPPORT ...........................................................................................................39

4.23 ASSEMBLING THE CABINET UPPER COVER .................................................................................................................40

4.24 ASSEMBLING THE CYLINDER BRACKETS ......................................................................................................................41

4.1 SMARTWAY 90 EXAMPLE 2 X 10 ......................................................................................................................................16

4.2 ASSEMBLY OF THE SUPPORTING COMPONENTS ......................................................................................................18

4.3 ASSEMBLING THE SUPPORTING ENTRANCE GATE COMPONENTS .....................................................................20

4.4 ASSEMBLING THE ENTRANCE GATE ...............................................................................................................................21

4.5 ASSEMBLING THE GUTTER ENDPIECES .........................................................................................................................22

4.6 ASSEMBLING THE CLASSIC CROSSBEAM .....................................................................................................................23

4.7 ASSEMBLING THE CLASSIC GUTTER .............................................................................................................................24

4.8 ASSEMBLING THE CLASSIC SPLASH PANEL .................................................................................................................25

4.9 ASSEMBLING THE SUPREME CROSSBEAM ...................................................................................................................26

4.10 ASSEMBLING THE SUPREME GUTTER . .........................................................................................................................27

4.11 ASSEMBLING THE SUPREME SPLASH PANE ................................................................................................................28

4.12 ASSEMBLING THE DETACHER BRACKETS FOR SUPREME CABINET . ...................................................................29

4.13 ASSEMBLING THE CURB .....................................................................................................................................................30

4.14 BITUMEN PROTECTIVE COATING ....................................................................................................................................31

4.15 ASSEMBLING THE LIFTING CYLINDERS .........................................................................................................................32

4.16 ASSEMBLING THE VERTICAL GUIDE CARRIAGE . ........................................................................................................33

4.25 ASSEMBLING THE UPPER FRONT COVER .....................................................................................................................42

4.26 ASSEMBLING THE LOWER FRONT COVER ....................................................................................................................43

4.27 ASSEMBLING THE PVC DETACHER CYLINDERS ..........................................................................................................44

4.28 ASSEMBLING THE STAINLESS STEEL DETACHER CYLINDERS ................................................................................45

4.29 ASSEMBLING THE COMPRESSED AIR LINE, CLASSIC RUMP RAIL ........................................................................46

4.30 ASSEMBLING THE COMPRESSED AIR LINE, SUPREME RUMP RAIL.......................................................................47

4.31 ASSEMBLING THE CONTROL CABINET ..........................................................................................................................48

1. PREFACE

Contents:

1.1 MANUFACTURER’S ADDRESS ................................................................................................................................................................... 4

1.2 CUSTOMER SERVICE ...................................................................................................................................................................................... 4

1.3 GUIDELINES, LAWS, STANDARDS ........................................................................................................................................................... 4

1.3.1 DECLARATION OF CONFORMITY ............................................................................................................................................................ 5

1.4 SUCCESSFUL MILKING .................................................................................................................................................................................. 6

2. SAFETY

2.1 OWNER’S DUTY OF CARE ........................................................................................................................................................................... 7

2.2 BASIC SAFETY INSTRUCTIONS .................................................................................................................................................................. 8

2.3 PERSONNEL QUALIFICATION .................................................................................................................................................................... 9

2.4 PROTECTIVE EQUIPMENT ..........................................................................................................................................................................10

2.5 SAFETY SIGNS, STICKERS AND LABELS ..........................................................................................................................................10

2.6 PACKAGING MATERIALS ............................................................................................................................................................................10

2.7 CORRECT APPLICATION ............................................................................................................................................................................10

3. DESCRIPTION

3.1 INSTALLATION CONDITIONS .............................................................................................................................................12

3.2 DELIVERY ................................................................................................................................................................ .................12

4. INSTALLATION

3.5 SYMBOLS..................................................................................................................................................................................14

3.3 STORAGE ..................................................................................................................................................................................13

3.4 GENERAL ASSEMBLY INSTRUCTIONS ........................................................................................................... .................13

3.6 RECOMMENDATIONS ..........................................................................................................................................................14

3.4 USE OF COMPRESSED AIR ............................................................................................................................... .................15

Page 3

9e1060

4.32 ASSEMBLING THE CONTROL CABINET ON CLASSIC RUMP RAIL .........................................................................49

4.33 ASSEMBLING THE CONTROL CABINET ON SUPREME RUMP RAIL. ......................................................................50

4.34 ASSEMBLING THE SUPPLY ARM ......................................................................................................................................51

4.35 NETWORK: ASSEMBLY BY PARLOUR SIDE ....................................................................................................................52

4.36 AIR SUPPLY DIAGRAM FRONT RAIL INDEXATION .....................................................................................................53

4.37 AIR SUPPLY DIAGRAM LIFTING CYLINDERS, FRONT RAIL AND ENTRANCE GATE ........................................54

4.38 ASSEMBLING THE POSITION SENSORS .........................................................................................................................55

4.39 OPTION: ASSEMBLING THE PROTECTIVE COVER ......................................................................................................57

5. WIRING DIAGRAM

7. DECOMMISSIONING

7.1 SPECIAL PERSONNEL QUALIFICATION REQUIRED FOR DECOMMISSIONING ..................................................60

7.2 SAFETY INSTRUCTIONS FOR DECOMMISSIONING ....................................................................................................60

7.3 SPECIAL DANGERS INVOLVED IN DECOMMISSIONING ............................................................................................60

7.4 FINAL DECOMMISSIONING / DISPOSAL ........................................................................................................................60

5.0 WIRING DIAGRAM .................................................................................................................................................................58

6. REPLACEMENT AND SPARE PARTS

6.0 REPLACEMENT AND SPARE PARTS ...................................................................................................................................59

Page 4

9e1060

1. PREFACE

These instructions are supplied with the product.

They should be kept close at hand and remain with the equipment even if the equipment is sold.

This manual is not covered by an amendment service. The current version can be obtained through your

technical dealer or directly from BouMatic.

We reserve the right to make changes of the data and illustrations in this manual due to technical

developments.

Reproduction, translation or copying in any form, including extracts, requires written authorization from

BouMatic.

1.1 MANUFACTURER’S ADDRESS

1.2 CUSTOMER SERVICE

If necessary, please contact your nearest authorised dealer.

1.3 GUIDELINES, LAWS, STANDARDS

BouMatic A/S

Jernvej 2

6900 Skjern

Denmark

Tel: +45 7694 5525

Fax: +45 7526 0396

BouMatic Gascoigne Melotte Sprl.

Rue Jules Melotte 31

4350 Remicourt

Belgium

Tel: +32 19 54 42 66

Fax: +32 19 54 55 44

BouMatic Europe

EMC compliance has been tested and this equipment meets the requirements of the applicable European

and national guidelines.

Conformity has been proved and the manufacturer holds the relevant statements and documents.

To maintain this state and ensure safe operation, you, as a user, must observe this operator manual.

Page 5

9e1060

1.3.1 DECLARATION OF CONFORMITY

IN PREPARATION

Page 6

9e1060

1.4 SUCCESSFUL MILKING

Prerequisites for successful milking:

• A milking installation designed in accordance with ISO 5707 or 3 A and set up correctly.

• Stable vacuum conditions due to an appropriately sized vacuum pump, a balance tank and vacuum

reserve as well as properly sized vacuum lines.

• Milking vacuum and automatic cluster removal must be set correctly to suit the animals.

Regular checks and adjustments to meet any herd changes will also ensure successful milking.

• A milking cluster selected to suit the animals.

• Correctly positioned cluster. Keep hoses as short as possible to avoid unnecessary sagging.

• Scheduled maintenance and cleaning of the milking installation. Regular thorough cleaning and

disinfection of the milking installation will help improve animal health, milk quality and therefore milking

results.

• When replacing parts, only use genuine BouMatic spare parts!

• Recommended settings are only valid in conjunction with genuine BouMatic products.

• The conscientious implementation of milking routines will have a positive eect on milking results.

Attention!

Milking without milk ow (overmilking) must be avoided, as it will very quickly have an adverse

eect on teat condition and udder health

Rub to

remove any

residual

bedding.

Dip with

pre-dip.

Strip/wash

teat end

with

gloved hand.

Dry with

one circular

motion - flip

towel and

aggressively

squeeze

teat end.

Attach

unit.

Adjust unit

for proper

placement.

Post-dip -

cover

complete

teat!!

10 to 12 seconds of teat contact

time. (stripping, washing and

drying)

Attach unit

within 75-90

seconds after

steps 3 and 4.

After attachment, adjust unit to

hang squarely on the cow as soon

as the last teat cup is attached.

Gently,

Quickly and

Completely

Always Milk Your Cows...

7 Step Udder Prep

BouMatic.com

1 2 3 4 5 6 7

Page 7

9e1060

2. SAFETY

2.1 OWNER’S DUTY OF CARE

Design and construction of this product were preceded by risk assessment and careful identication of applicable

harmonized standards and other technical specications. This product therefore represents the state-of-the-art

of technology and ensures a maximum level of safety. To achieve safety on farms, all necessary measures must be

taken. The owner is responsible for planning such measures and for verifying their implementation.

In particular, the owner has to ensure the following:

• Legal requirements must be met.

• Instructions on basic safety precautions must be followed.

• Safety signs, stickers and labels on the product must be replaced immediately if they are illegible or lost!

• All applied safety signs or warning instructions must stay in place and remain legible.

• Escape routes must be indicated by signs in accordance with national regulations!

• The required personal protection equipment must be available and used by operators, maintenance and

service personnel.

• A full set of legible instructions must always be kept near the product. Anyone having to work on the

product must have the possibility to look into the instructions at any time.

• The owner has to ensure that his sta receive adequate training adapted to suit the specic conditions of

his facility; emphasis should be placed on safety aspects.

• Unauthorised persons (e.g. children) are not permitted into hazardous areas and must not have access to

cleaning agents or disinfectants.

• Anyone involved in the operation, maintenance, inspection or handling of this product in any other way

must know and understand this manual (especially the safety information and warnings).

• This product

-should only be used for its intended purpose.

-should only be used if in perfect operating condition. The safety equipment, in particular, should be

regularly checked to make sure it is in perfect operating condition.

• Operating personnel who require training may only work on the product under the supervision of an

experienced person. The successful completion of training is to be conrmed in writing.

• Persons carrying out work on this product must be suciently qualied!

Page 8

9e1060

• There are dangers involved in the operation and maintenance of dairy farm equipment. For your own safety,

please read and observe these instructions carefully (especially the section on “Safety instructions”).

• Permissible working conditions (pressure ranges, temperature ranges, airow quantities etc.) must be ob-

served!

• Do not open or dismantle any devices (risk of injury)!

Do not remove any protective devices (risk of injury)!

• When working with cleaning and disinfecting agents observe the notes on dangers and protective measures

(risk of caustic burns)!

• When working with products from other manufacturers always observe the warnings on the material safety

data sheets and the operating instructions of the manufacturer!

• Observe noise protection measures!

• Do not stand underneath suspended loads.

• Always keep control cabinets, all power supply units and electrical control units closed.

Access is only permitted to authorized personnel with a key or special tool.

• Protect live and high-voltage components against moisture.

Water jets and high-pressure cleaners must NOT under any circumstances be directed at them!

2.2 BASIC SAFETY INSTRUCTIONS

Work to be performed by qualied personnel only:

-Transportation

-Handling

-Maintenance

-Cleaning

Work to be performed by authorized personnel only:

-Installation

-Start-up

-Service

-Troubleshooting

-Repairs

-Decommissioning

These personnel will be regularly instructed in all relevant matters of safety at work and protection of the environ-

ment and by familiar with this manual, particularly the safety instructions it contains.

Attention!

Page 9

9e1060

Anyone carrying out work or activities in connection with the product must carefully read the manual and sign to

conrm that they have understood it and will act accordingly!

Responsibilities:

• AC power wiring for voltage over 40 V (in Europe 50 V) must be done by a qualied (licensed) electrician in

compliance with the latest edition of the ANSI/ NFPA-Standard 70, National Electrical Code (USA) or either LVD

2006/95/EC or EMC 2014/30/EU (in Europe) and in compliance with the local wiring codes as applicable.

• Any work on the hydraulic and pneumatic equipment should only be performed by specialist personnel trained

for this purpose.

• Any welding should only be performed by specialist personnel with knowledge in welding.

• Other installation, major maintenance, and service work must be done by an authorized BouMatic dealer.

• Product / system checkout and troubleshooting must be done by an authorized BouMatic dealer.

In addition, special qualications are required for the following activities:

• Transportation

• Handling

• Maintenance

• Cleaning

• Installation

• Start-up

• Service

• Troubleshooting

• Repairs

Deviation from these instructions could aect product performance or create a hazardous situation. Under no

circumstances will BouMatic be responsible for any problems caused in whole or in part by a deviation from the

procedures specied in these instructions without prior written approval from BouMatic.

Operation steps may be performed by the owner/operator once the dealer or technician has successfully nished

the product/system checkout. The owner/operator is responsible for properly operating, maintaining, and moni-

toring the product/system to ensure that it works properly.

Disclaimer

No warranties are contained in these instructions. The division of responsibilities, stated above, is a general reminder

of those provisions in the applicable dealer contract and does not change any agreement between BouMatic and

the dealer. Information in these instructions is not all-inclusive and cannot cover all unique situations.

2.3 PERSONNEL QUALIFICATION

Page 10

9e1060

Attention!

2.4 PROTECTIVE EQUIPMENT

• Existing protective equipment should be checked at regular intervals to ensure their eective-

ness!

• Risk of death from electric shock!

Covers of electrical connection boxes must always be closed, otherwise there is danger of contact with

live parts.

• Risk of burns from acidic or alkaline detergents!

Risk of eye injuries or skin irritation.

• Risk of injury by putting your hand into the vacuum system!

Never reach into openings of the system when the machine is running. Extremities could be sucked in

by the vacuum prevailing in the system.

2.5 SAFETY SIGNS, STICKERS AND LABELS

Safety signs, stickers and labels axed to the product must be replaced immediately when illegible or lost!

2.6 PACKAGING MATERIALS

Packaging materials must be disposed of in accordance with applicable local regulations!

BouMatic equipment and components are designed exclusively for agricultural facilities (mostly dairy farms).

This product/component is designed exclusively for use during the milking process in parlours for cows or goats.

Any application not listed here is not part of the intended purpose and therefore considered as improper use!

The manufacturer / supplier is not liable for any resulting damage. The user alone bears the risk.

Correct use also includes reading the instructions and observing the inspection and maintenance conditions.

Genuine BouMatic parts and accessories are specially designed for BouMatic components; use only genuine spare

parts.

2.7 CORRECT APPLICATION

Page 11

9e1060

Attention!

• Please note that parts or accessories not supplied by us and instructions not provided by BouMatic

are not checked or released by us either.

• If such products are installed or used, this can have a negative eect on the specied properties of

BouMatic products and put people and animals at risk.

• The manufacturer cannot be held liable for injury to people and animals or for damage to Bou-

Matic products caused as a result of using non-original parts or accessories or by incorrect settings.

• During repair and service operations, always cut the power to the control unit by turning o the

switch.

• The control unit contains 230/400 V AC circuits and may only be opened by a BouMatic installer or a

qualied electrician.

• Installation, together with any repairs during the warranty period, may only be undertaken by an

authorised BouMatic dealer/installer, or in accordance with instructions from BouMatic, otherwise

the warranty will be invalid.

Page 12

9e1060

3. DESCRIPTION

3.1 INSTALLATION CONDITIONS

The SmartWay 90 milking parlour must be installed in a building (under a roof), protected against negative weather

conditions.

The premises should have a minimum temperature of 5° Celsius and not have excessive humidity levels.

The installation conditions of the SmartWay 90 with regard to the external electrical and water connections, the structural

building conditions and other conditions on site do not fall within the sphere of responsibility of BouMatic.

Please follow the instructions in this manual.

Objects or other components that are added to the system or are located/assembled nearby must not interfere in any

way with its correct and safe operation.

To operate the SmartWay 90 milking parlour, two energy carriers must be available:

1- Electrical power supply: 230 V, 50 Hz (Europe)

2- Pneumatic energy: compressed air 8 bar, constant and oil free

The system is operated by a control unit installed in the milking pit so that the controlled actions can bemonitored.

Please check the scope of delivery of the delivered goods and conrm receipt.

Please check the delivered goods against the order conrmation and delivery note for correctness and possible

transport damage.

Damages or apparent inconsistencies must be reported in writing within 48 hours of delivery.

Ensure that the machine used to unload the system from the lorry (forklift, tractor with front loader, etc.) has the

appropriate power.

The weight per pallet varies according to the milking parlour size.The weight does not exceed 3000 kg per

pallet/unit however.

3.2 DELIVERY

Receipt of goods:

BouMatic cannot be held liable for damage caused by improper unloading!

Do not stay under suspended loads during unloading and later assembly!

Page 13

9e1060

3.3 STORAGE

The following rules must be observed when storing the delivered goods:

Do not store the product outdoors or in areas with chemical vapours, moisture, excessive temperature and/or

dirt.

Do not store the product on the bare oor/ground.

Ensure proper storage of electrical components and/or fragile objects.

Strong exposure by e.g. exposure to sunlight at high humidity inuences the appearance of metal parts and

can cause damage to electrical and pneumatic components.

Plastics can change in colour due to excessive UV radiation and, in extreme cases, can become brittle.

3.4 GENERAL ASSEMBLY INSTRUCTIONS

The milking parlour is delivered in individual parts. It must be assembled by trained personnel, taking into account the

contents of this manual.

Installation personnel must have knowledge of the type of installation and possible risks.

The instructions in this manual must be followed. BouMatic accepts no responsibility or warranty for damages resulting

from improper installation and their consequential damage.

The following information must be observed:

During welding operations, in particular of galvanised parts, harmful gases can lead to damage to health. Avoid

breathing these vapours and ensure adequate ventilation.

Adaptations, e.g. cutting certain parts, requires mechanical expertise.

A bitumen coating shall be applied to all parts to be encased in concrete up to 50 mm (2“) above the top edge

of the nished concrete.

If possible, use greases approved for the food industry, such as“Unil Opal Polyfood 2”or a comparable lubricant.

Always grease stainless steel screws before mounting..

If you weld galvanised surfaces or galvanised parts mechanically, immediately apply a new zinccoating.

For screw connections, observe the permissible torques (see table on the next page).

Page 14

9e1060

3.5 SYMBOLS

Explanation of symbols used in this manual:

Grind

Drill

Grease

Galvanize

Weld

Grease the screws

Left side

Right side

Apply protective

paint

3.6 RECOMMENDATIONS

Before commissioning the system, it must be ensured that the installation of the system complies with the

technical guidelines and national laws.

The control elements must be installed in such a way that the functions they set in motion can be monitored by

the operator.

The highest priority is the safety of humans and animals.

Failure to do so could result in serious, permanent injury.

All electrically conductive system components must be connected to the building’s potential

equalization.

Ø Screw

Torques of the xing screws (Nm)

Strength class

4.6 4.8 5.6 5.8 6.6 6.8 8.8 10.9 12.9

M4 1.12 1.50 1.40 1.87 1.68 2.25 3.00 4.21 5.06

M5 2.17 2.89 2.71 3.62 3.26 4.34 5.79 8.15 9.78

M6 3.74 4.90 4.60 6.24 5.62 7.49 9.99 14.00 16.80

M8 8.92 11.90 11.10 14.80 13.30 17.80 23.70 33.40 40.10

M10 17.90 23.80 22.40 29.80 26.80 35.80 47.70 67.20 80.60

M12 30.40 40.50 38.00 50.70 45.60 60.80 81.10 114.10 137.00

M16 73.40 97.90 91.80 122.40 110.20 146.90 195.90 275.60 330.70

M20 143.20 191.00 179.00 238.70 214.80 286.50 382.00 537.10 644.60

Page 15

9e1060

3.7 USE OF COMPRESSED AIR

Number of cylinders and compressed air consumption - SmartWay 90

Milking parlour size 2x3 2x4 2x5 2x6 2x7 2x8 2x9 2x10 2X11 2X12

Number of lifting cylinders Ø 100 x 850 4 6 8

Number of index cylinders Ø 100 x 250 4 6 8

Number of entrance door cylinders Ø 63 x 400 2 2 2

Calculated required compressed air ow at 6 bar in l/min. 152 220 288

Calculated required air volume at 6 bar in l/h. at 4 passages / hour. 202 293 384

Milking parlour size 2x14 2x16 2x18 2x20 2x24 2x28 2x32 2x36 2X40 2X44 2X48

Number of lifting cylinders Ø 100 x 850 10 12 14 16 18 20 22 24 26

Number of index cylinders Ø 100 x 250 10 12 14 16 18 20 22 24 26

Number of entrance door cylinders Ø 63 x 400 2 2 2 2 2 2 2 2 2

Calculated required compressed air ow at 6 bar in l/min. 357 425 493 562 630 698 767 835 903

Calculated required air volume at 6 bar in l/h. at 4 passages / hour. 475 567 658 749 840 931 1022 1113 1204

Page 16

9e1060

4. INSTALLATION

4.1 SMARTWAY 90 EXAMPLE 2 X 10

0

2880

113.3 ''

400

15.7 ''

180

7 ''

610 MAXI -- 24''

455 mini -- 18''

(1135)

(44.7 '')

2000

78.7 ''

4%

(2410)

(94.7 '')

2420 MAXI -- 95.3''

1830 mini -- 72'' 776

30.5 ''

(1070)

(42 '')

((selon opérateur) )

(2680 )

(105.4 '')

Largeur de couloir =

2670 + ( 40 x nb de postes par côté )

= 105'' + (1.6'' x nb post)

2122

83.5 ''

O(76)

(3 '')

Adapted to the height

of the milker

min.

min.

max.

max.

Corridor width =

2670 + (40 mm x number of

milking places per side)

105 "+ (1.6" x number of

milking places per side)

Page 17

9e1060

A

DE

TAIL A

Zone dégagée : accés armoire de commande

2220

87.4 ''

(3 places)

2960

116.5 ''

(4 places)

2220

87.4 ''

(3 places)

865

34.1 ''

150

5.9 ''

210

8.3 ''

2000

78.7 ''

longueur stalle = ( 740 x nb de postes par côté ) + 700 -- ( 29.13'' x nb post ) + 27.5'

'

(510)

(20.1 '')

(740 )

(29.1 '')

530

21 ''

3 places

4 places

3 places

Milking parlour length = (740 mm x number of milking places per side) + 700 mm

Milking parlour length = (29.13 '' x number of milking places per side) + 27.5 ''

Size Size

Distribution and size of

front rail elements

Distribution and size of

front rail elements

Free area: access to the control cabinet

DETAIL A

Page 18

9e1060

4.2 ASSEMBLY OF THE SUPPORTING COMPONENTS

8 Mitteltraverse SMARTWAY 90 BOSW100507

7 Rohrabdeckung rechteckig 140x80 BOBT014080

6 selbstsichernde Mutter H M10 BOECF00010

5 Rechteck-Bügelschellen 140x80 ...

4 Haupttraverse rechts/links BOSW100500

3 Mutter H M10 ...

2 Dübelanker FBN M 10x175 BOFBN10175

1 Standpfosten SMARTWAY 90 BOSW000500

Beschreibung

A

DETAIL A

Teilenummer

1

2

3

4

5

6

7

5

7

6

8

1

345

20

20

O 30

70( env. )

( 2.75 '')

Avant-projet 0310 SW 005 - Poteaux - beams

DETAIL A

(ca. 70)

Pos. Description Part number

1Support post SMARTWAY 90 BOSW000500

4Plug anchors FBN M 10x175 BOFBN10175

3Nut H M10

4Main cross beam right/left BOSW100500

5Rectangular U-bolts 140x80

6Self-locking nut H M10 BOECF00010

7Cover, rectangular pipe 40x80 BOBT014080

8Central beam SMARTWAY 90 BOSW100507

Page 19

9e1060

=

=

740 x n places

29.13 ''

740 x n places

29.13 ''

740 x n places

29.13 ''

Avant-projet 0310 SW 010 - Poteaux - contrôle implantation

x Number of places

740 mm (29,13“) 740 mm (29,13“) 740 mm (29,13“)

x Number of places x Number of places

Important!

Check and adjust:

• Correct height and position of the support posts.

• Diagonal length (spacing) and vertical alignment of the support posts.

• Sturdiness and stability of the support posts in the concrete

• Correct distribution of the support posts at a distance of 740 mm or 29.13"

• The support posts must be absolutely perpendicular in any vertical direction.

Page 20

9e1060

6 Ecrou frein H M10 BOECF00010 ...

5 Etrier rectangulaire 140x80 ... ...

4 Ecrou H M10 ... ...

3 Rondelle L 10 ... ...

2 Chevilles d'Ancrage FBN M 10x175 BOFBN10175 ...

1 POTEAU PORTE GUILLOTINE SMARTWAY 90.

C.Ga

BOSW000507 ...

NĀ Désignation Réf.Binet Réf.Boumatic

A

DETAIL A

B

DETAIL B

1

2

3

4

5

63

865

34 ''

//

Check the parallel alignment

of the entrance gates to the

respective beams.

4.3 ASSEMBLING THE SUPPORTING ENTRANCE GATE COMPONENTS

Pos. Description Part number

1Support post entrance gate SmartWay 90 BOSW000507

2Plug anchors FBN M 10x175 BOFBN10175

3Flat washer M 10

4Nut M 10

5Rectangular U-bolt 140x80

6Self-locking nut H M10 BOECF00010

DETAIL A

DETAIL B

Table of contents

Other Boumatic Farm Equipment manuals

Boumatic

Boumatic HandyFloor 2015 Manual

Boumatic

Boumatic Xpedia 360IX User manual

Boumatic

Boumatic 5450 Installation and user guide

Boumatic

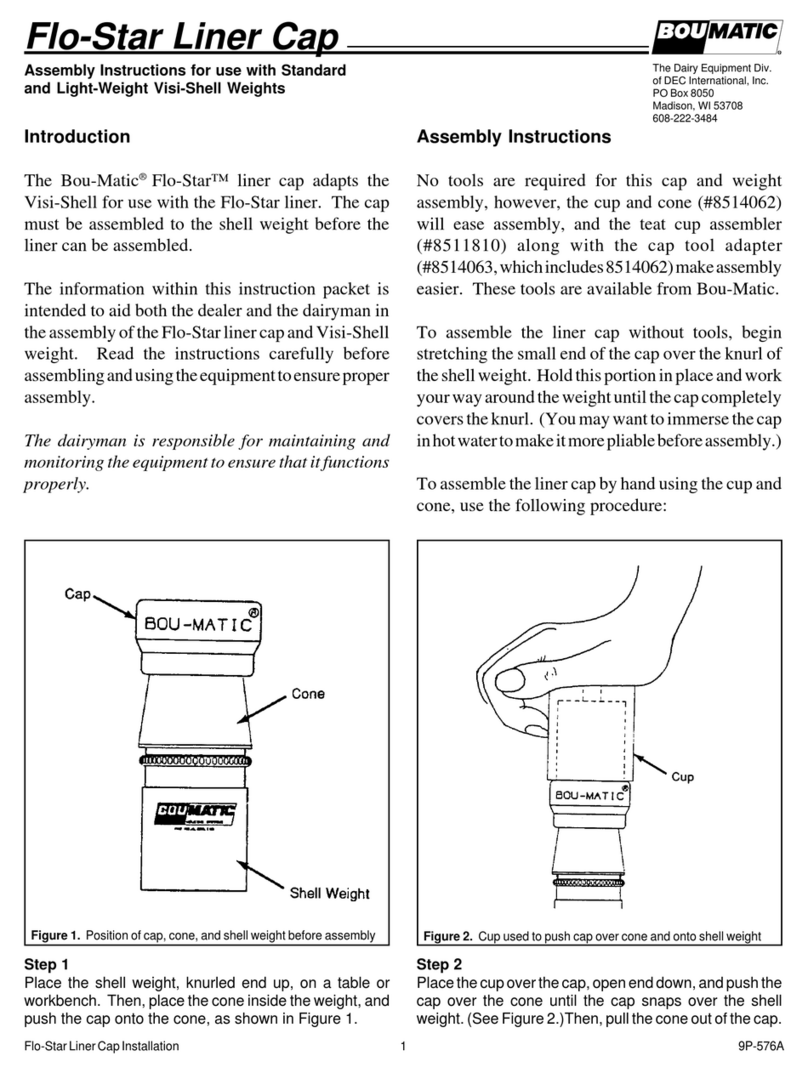

Boumatic Flo-Star Liner Cap User manual

Boumatic

Boumatic HD2 Rapid Exit User manual

Boumatic

Boumatic Xpedia 360 EX User manual

Boumatic

Boumatic FORMULE 1 User manual

Boumatic

Boumatic HD2 Rapid Exit User manual

Boumatic

Boumatic GT2" User manual