6334 Installation

21/23/09 Bradley Corporation • P20-150 Rev. D; ECN 09-15-0002

Soap Dispenser Care and Maintenance

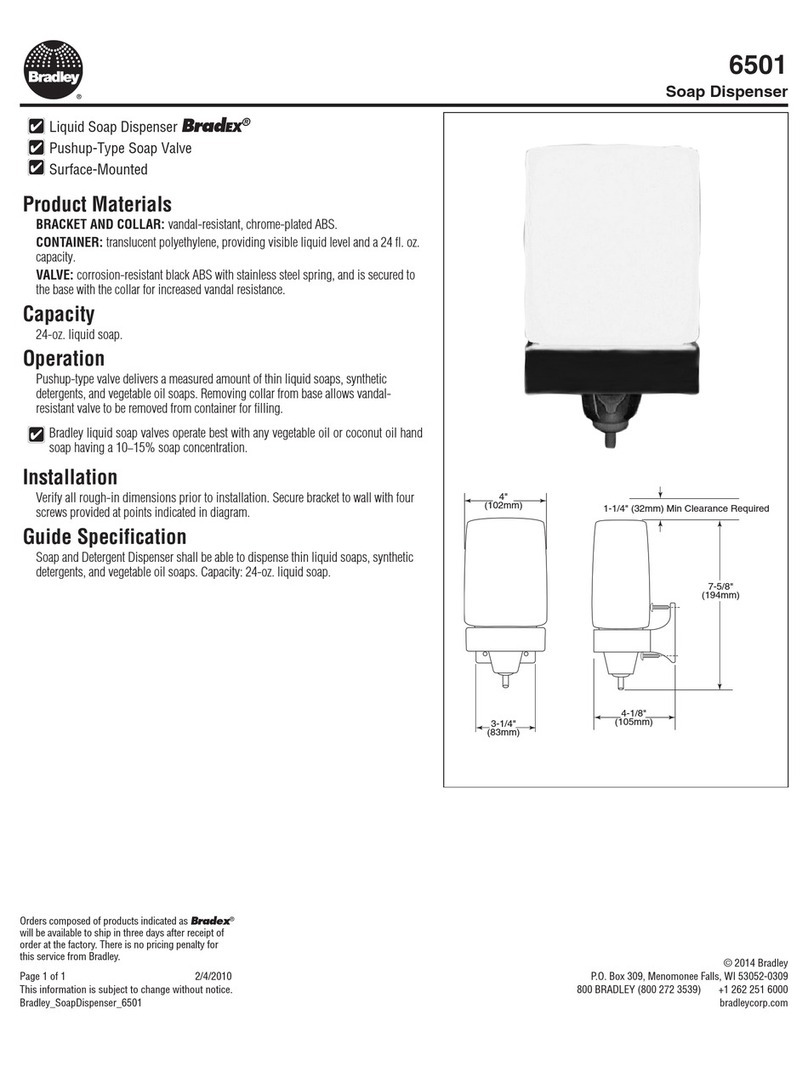

The 6334 Soap Dispenser will dispense vegetable or coconut oil liquid soaps, synthetic detergents, and

antiseptic solutions in a liquid form. A 10–15% concentration is recommended for vegetable or coconut oil liquid

soaps. Synthetic detergents and antiseptic soaps require no dilution.

Regular cleaning is advised for a soap dispenser in order that it may provide optimum performance and

maximum service life. Cleaning the soap dispenser monthly to remove soap residue, dirt, and other

accumulations should become a regular part of your washroom cleaning routine and general maintenance

program.

General Cleaning of Soap Dispenser

1. Use warm water and soap to clean the exterior of the soap dispenser. Do not use abrasive cleaners on

the metal parts of the soap dispenser. Dry and polish with a soft cloth for a bright finish.

2. Inspect the interior of the soap bottle for residue or coagulation of soap. If residue or coagulation exists,

clean the soap bottle. To clean the soap bottle,

• pour out any remaining soap.

• fill the bottle half full of hot water and shake well to dislodge the soap residue.

• empty the water from the bottle.

Repeat these three steps until the soap bottle is clean.

3. To clean the internal components of the soap dispenser, simply pump hot water through the soap

dispenser until a clean flow of water comes out of the spout.

Changing Soap Types

1. Unscrew the soap bottle from the shank and pour out all the remaining soap. Using hot water, rinse the

bottle two or more times until all the residue is eliminated. In addition, pump the valve several times with

hot water until a clear flow of water appears. Follow these steps with a rinse of ethyl alcohol (ethanol) and

shake out thoroughly. Let the soap dispenser air dry.

2. After the dispenser is dry, reattach the soap bottle to the shank.

3. Unscrew the valve assembly from the shank using the wrench provided and withdraw it from the soap

bottle.

4. Pour the liquid soap into the top opening of the shank.

5. Replace the valve assembly and tighten with the wrench provided.

6. Pump the soap valve several times to “prime” the unit.

Soap Dispenser Maintenance

Because many of the problems with soap dispensers are caused by a build-up of soap residue, it is

recommended that the internal components of the soap dispenser be cleaned periodically. To clean the soap

dispenser components, follow the procedure outlined below:

1. Remove the plunger, flange and pump assemblies from the shank.

2. Clean the internal parts of the soap dispenser using hot water and a soft bristle brush.

3. Reassemble the soap dispenser.