4. OPERATION INSTRUCTIONS

1. Open housing with included security key.

2. Open cover on battery compartment, remove battery box and unplug cable.

Install four (4) new Alkaline Type AA 1.5V batteries with correct polarity

(note the +/- indication) to obtain 6V DC ± 10% at the plug.

3. Reinstall battery box and close compartment cover.

4. Remove, clean out and refill the included reusable soap reservoir with foam soap,

ensure that soap container cover is closed, air vent hole is open and nozzle is not clogged.

The soap container should be clean (no spill over) and not leaking. Install the reusable reservoir

into the dispenser. Make sure the nozzle flange is below the housing cradle rib to stretch the

valve tube.

5. Make sure to latch the cradle gate.

6. Close the housing cover and lock it with the included security key previously retained.

7. Observe that the LED light is blue and then flashes four (4) times. This indicates that

the environment has been detected.If there is no object under the dispenser,

the default sensing distance is 3.15" to 3.93" (80mm to 100mm). If there is an object

(such as a basin or counter)under the dispenser, the sensor will detect the installation

height and environment light to set a suitable sensing distance automatically.

8. Trigger the sensor with hands or a towel to check proper soap dispensing cycle .

6. BATTERY LOW INDICATION

With housing cover open and soap reservoir removed

(see Instructions) perform the following diagnostic test:

1.Press and push up the cover safety interlock switch

(blue stem) on bottom to click and hold it.

2.Observe that the LED

3.If LED continue s

positive to replace the batteries.

is lit blue and then flashes

four (4) times indicating proper operation “stand-by”

condition and battery charge level.

s to flash blue the indication i

1. Ensure no bright source is aimed or reflected at the

sensor from below.

2. Use fresh new foam soap only and clean the soap

container properly before each re-fill. Deposits of old

soap will lead to malfunction and jamming.

3. Do not dilute foam soap unless concentrate and do not

use soap containing abrasive. Observe indicated

viscosity factor of foam soap.

4. Do not immerse the soap dispenser in water or clean it

under running water. This will lead to short circuit.

5. Should the dispenser be out of order and batteries have

been replaced, do not attempt any repair work. Call your

dealer for professional assistance.

5.IMPORTANT NOTICE

AA (1.5V)

Caution : Batteries installed with incorrect polarity may cause malfunction.

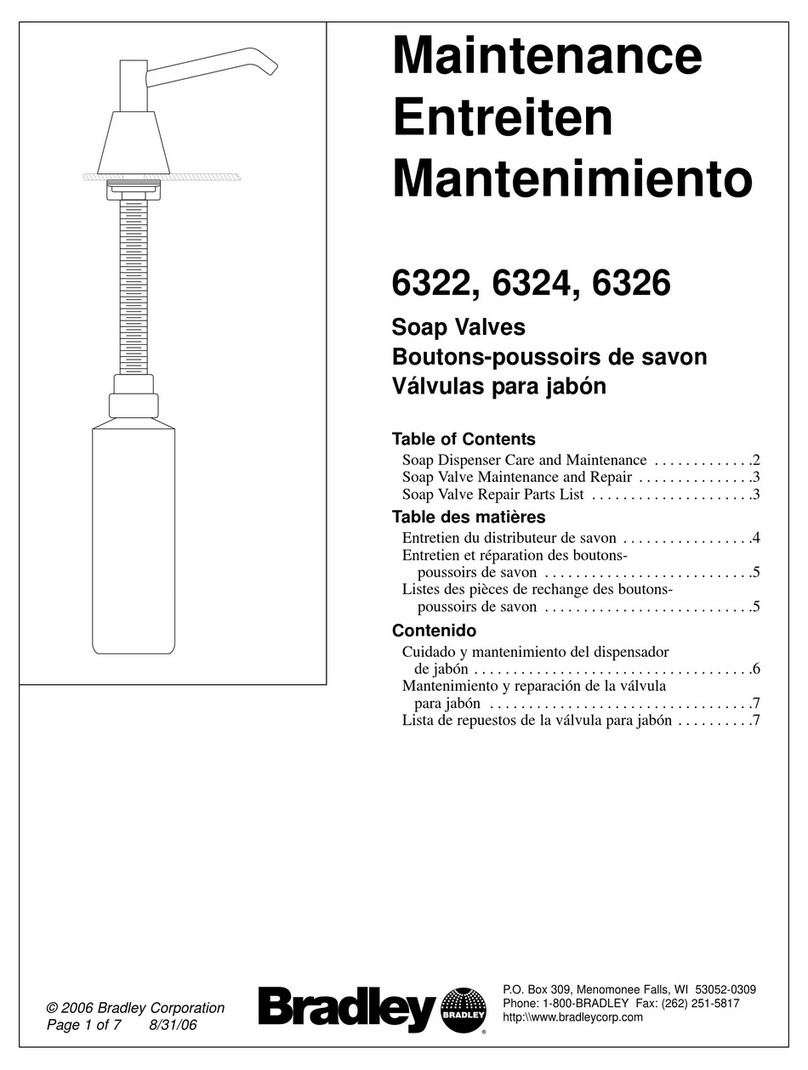

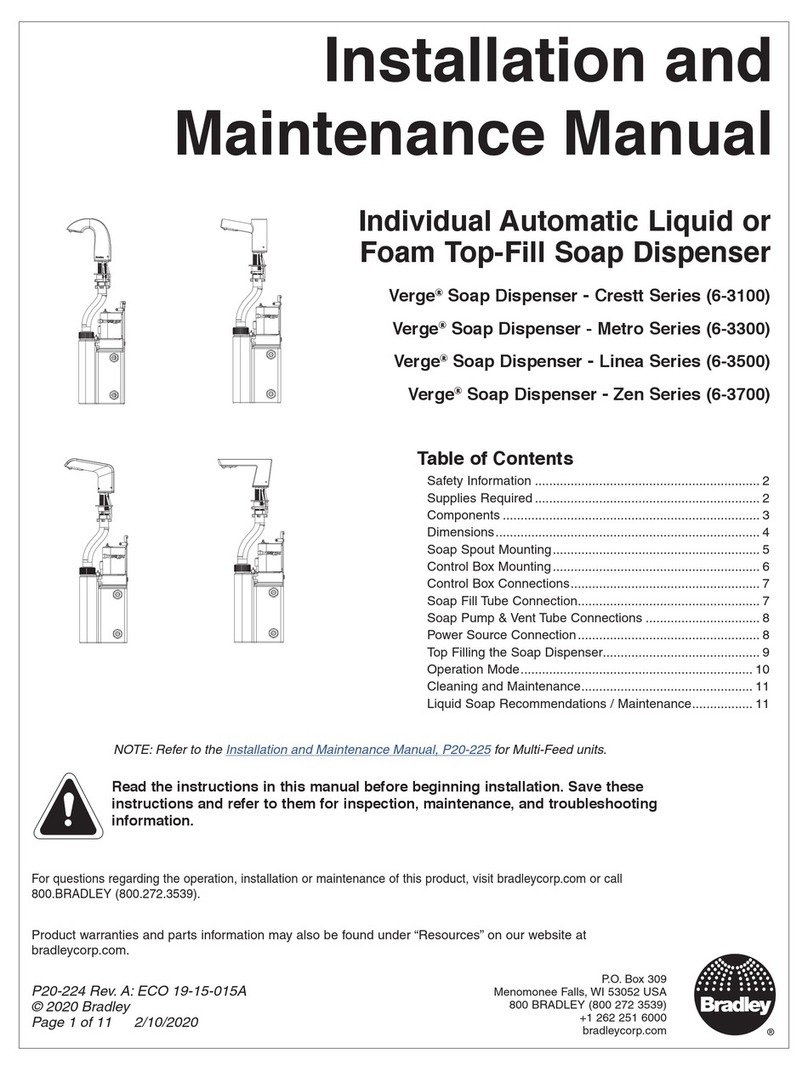

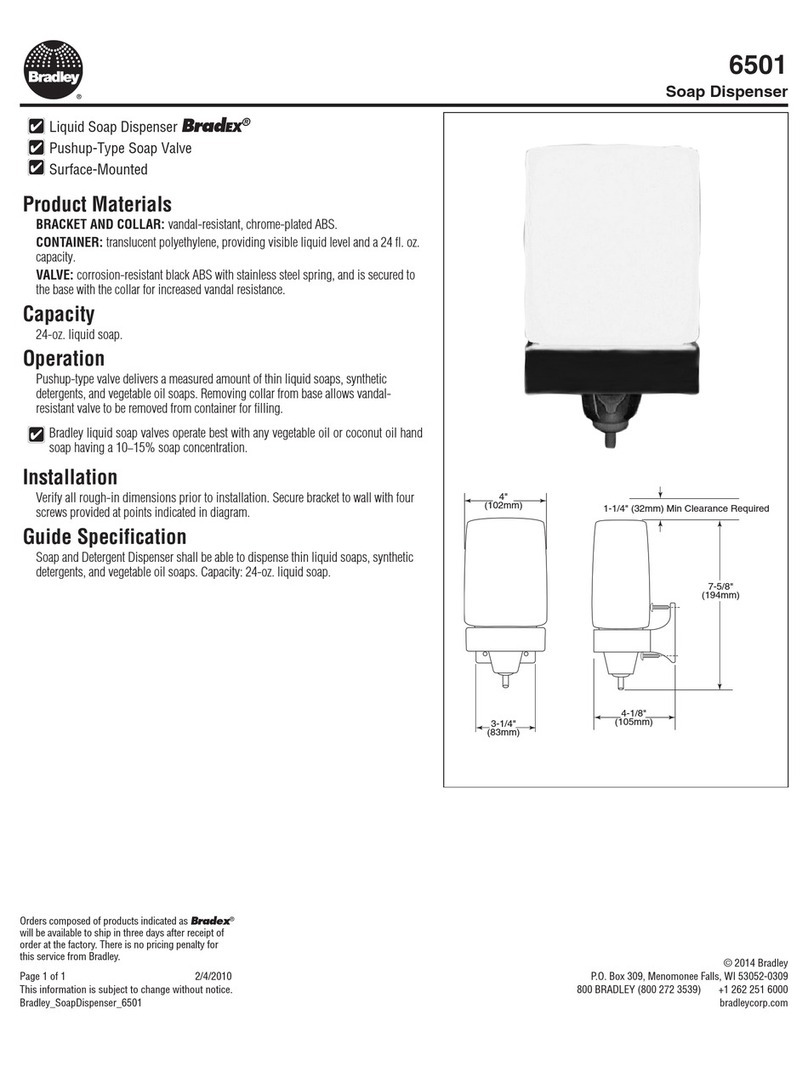

7. Diagram

Base plate

Soap tank

Key

Lock

Spout nozzle

Valve pump

Tank cover

Cover

Electronic box

Battery box

Nut

Hinge nut Hinge screw

Retainer

screw

2

8. Provided in kit

1. Key x 1

2. Plastic Anchor x 4

3. Mounting Screw x 4

4. Mounting Template x 1

5. Self-adhesive Tape x 3