Installation and

Maintenance Manual

P.O. Box 309

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

P20-225 Rev. A: ECO 19-15-015A

© 2020 Bradley

Page 1 of 19 2/12/2020

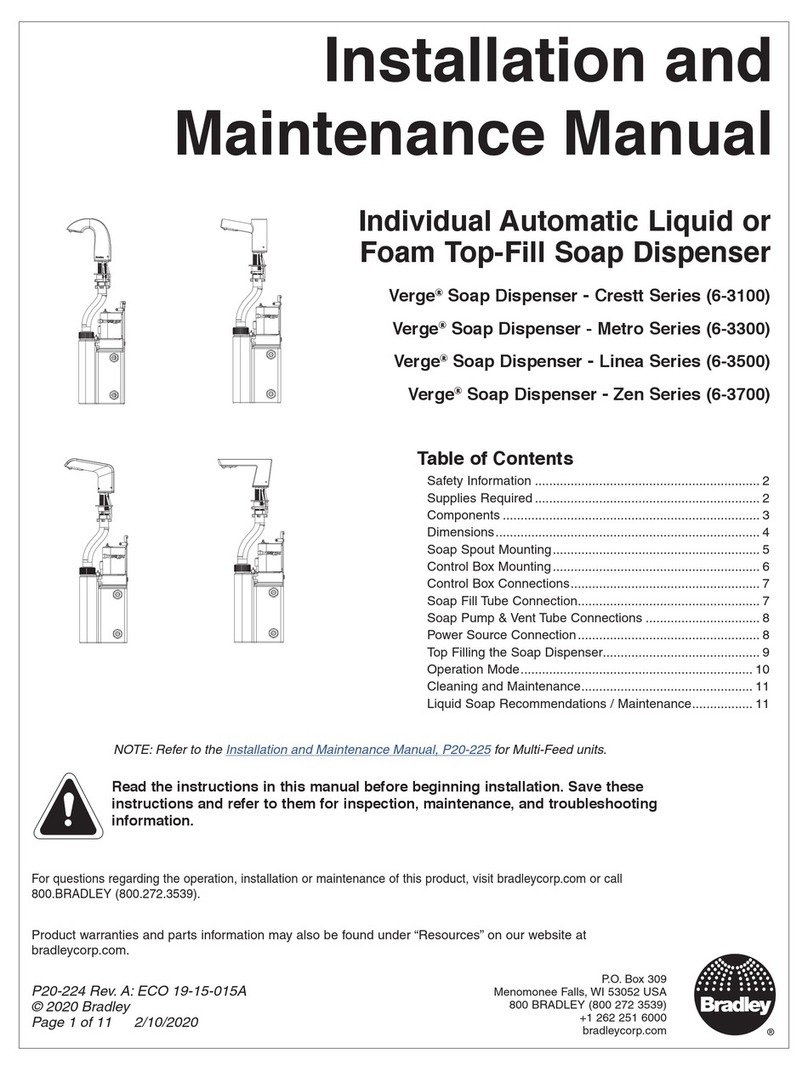

Verge®Multi-Feed Soap Tank

Verge®Soap Dispenser -Crestt Series (6-3100)

Verge®Soap Dispenser - Metro Series (6-3300)

Verge®Soap Dispenser -Linea Series (6-3500)

Verge®Soap Dispenser -Zen Series (6-3700)

Table of Contents

Safety Information ............................................................... 2

Supplies Required ............................................................... 2

Components ........................................................................ 3

Dimensions.......................................................................... 4

Soap Spout Mounting.......................................................... 5

Control Box Mounting .......................................................... 6

Control Box & Soap Supply Connections............................ 7

Multi-Feed Soap Tank Assembly Mounting ......................... 8

Soap Supply Connections ................................................. 12

Power Supply Connections................................................ 16

Adding Soap to Multi-Feed Soap Tank Assembly ............. 17

Operation Mode................................................................. 18

Cleaning and Maintenance................................................ 19

Liquid Soap Recommendations / Maintenance................. 19

Read the instructions in this manual before beginning installation. Save these

instructions and refer to them for inspection, maintenance, and troubleshooting

information.

For questions regarding the operation, installation or maintenance of this product, visit bradleycorp.com or call

800.BRADLEY (800.272.3539).

Product warranties and parts information may also be found under “Resources” on our website at

bradleycorp.com.

NOTE: Refer to the Installation and Maintenance Manual, P20-224 for individual automatic top-fill soap dispensers.