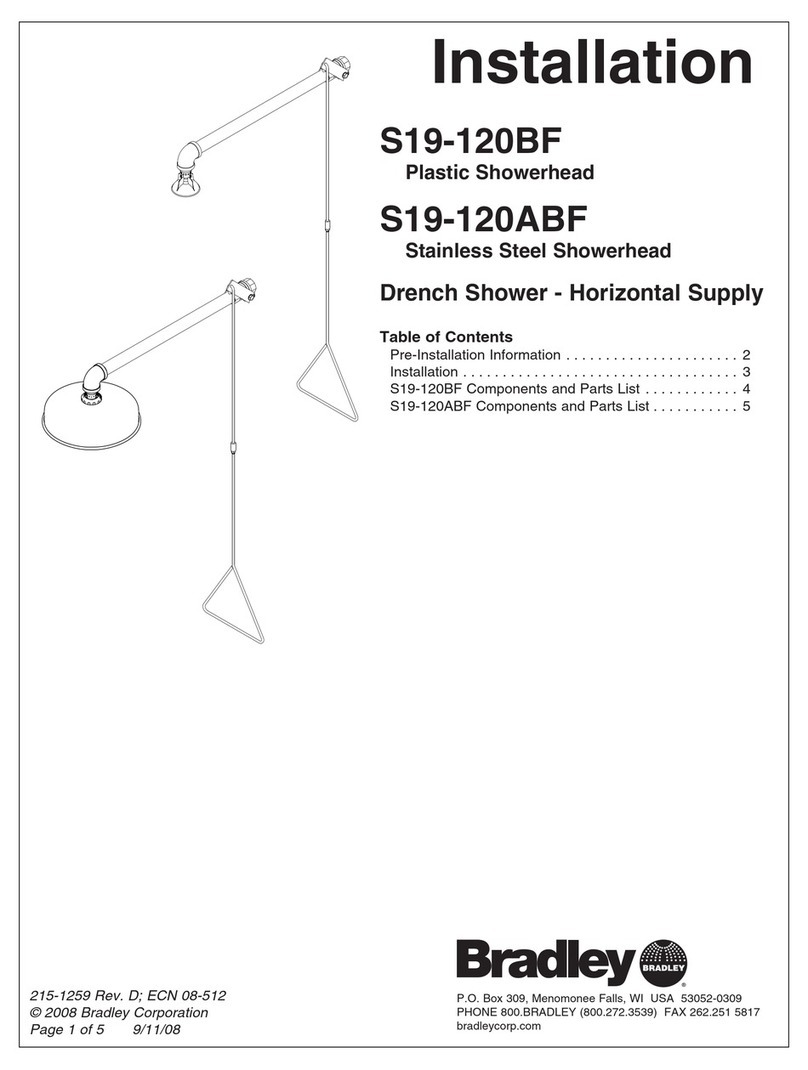

Bradley S19-120FMBF User manual

Other Bradley Plumbing Product manuals

Bradley

Bradley Bradmar 700 Series User manual

Bradley

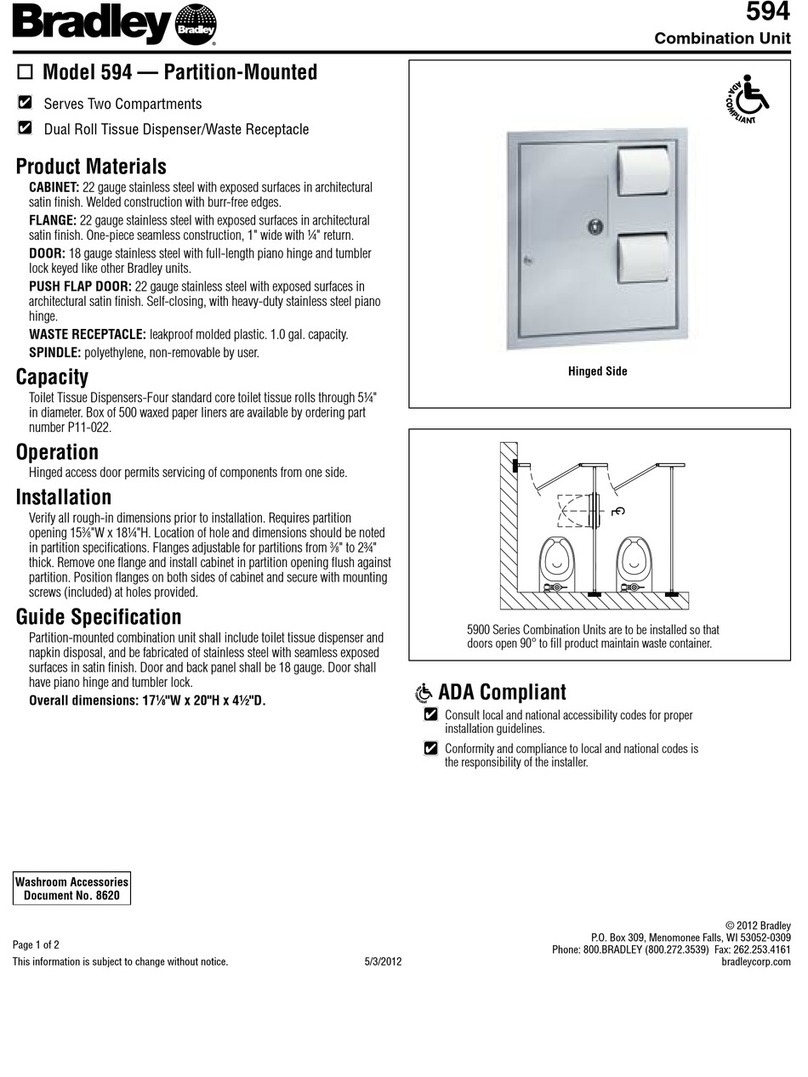

Bradley 594 User manual

Bradley

Bradley S59-2005 User manual

Bradley

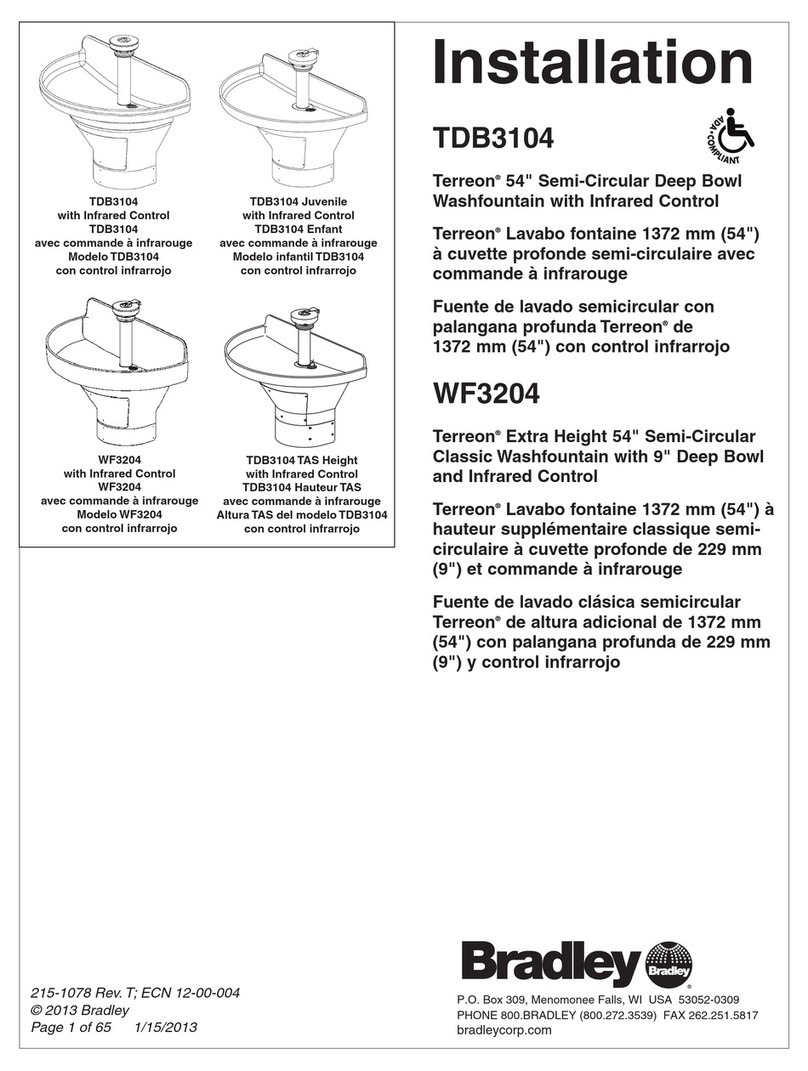

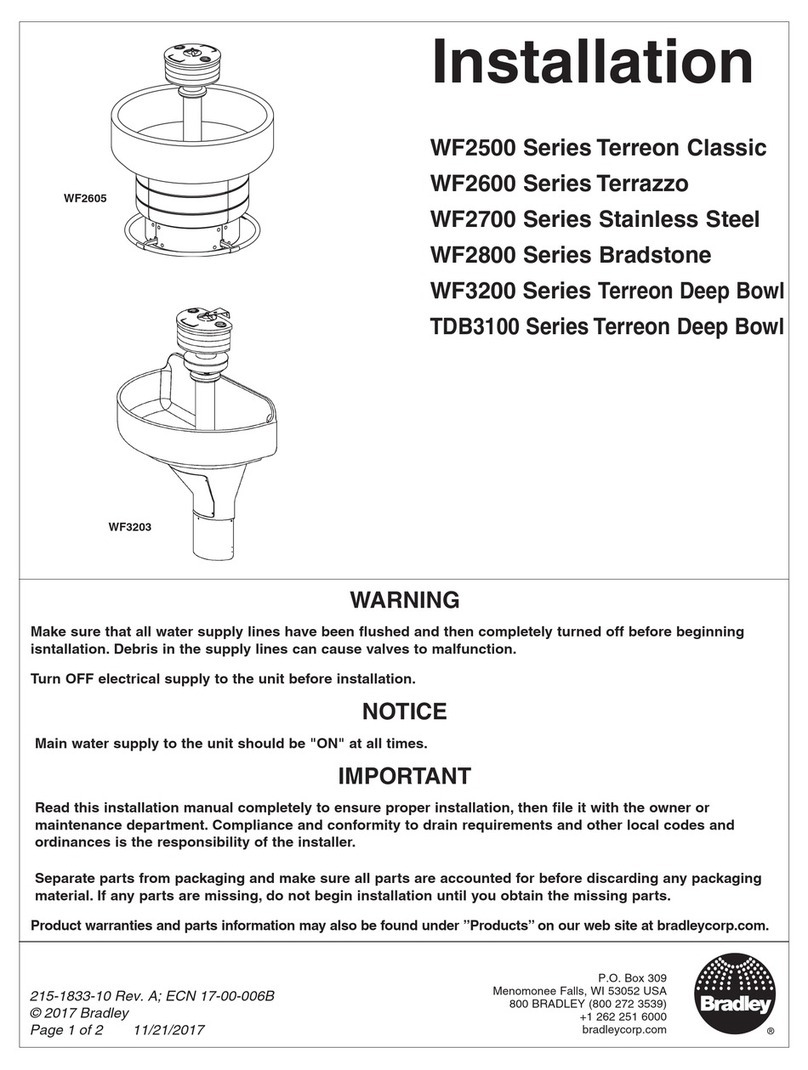

Bradley Terreon WF3204 User manual

Bradley

Bradley Terrazzo WF2600 Series User manual

Bradley

Bradley SS-2/IR/JUV User manual

Bradley

Bradley EXD-2N User manual

Bradley

Bradley S19-690 User manual

Bradley

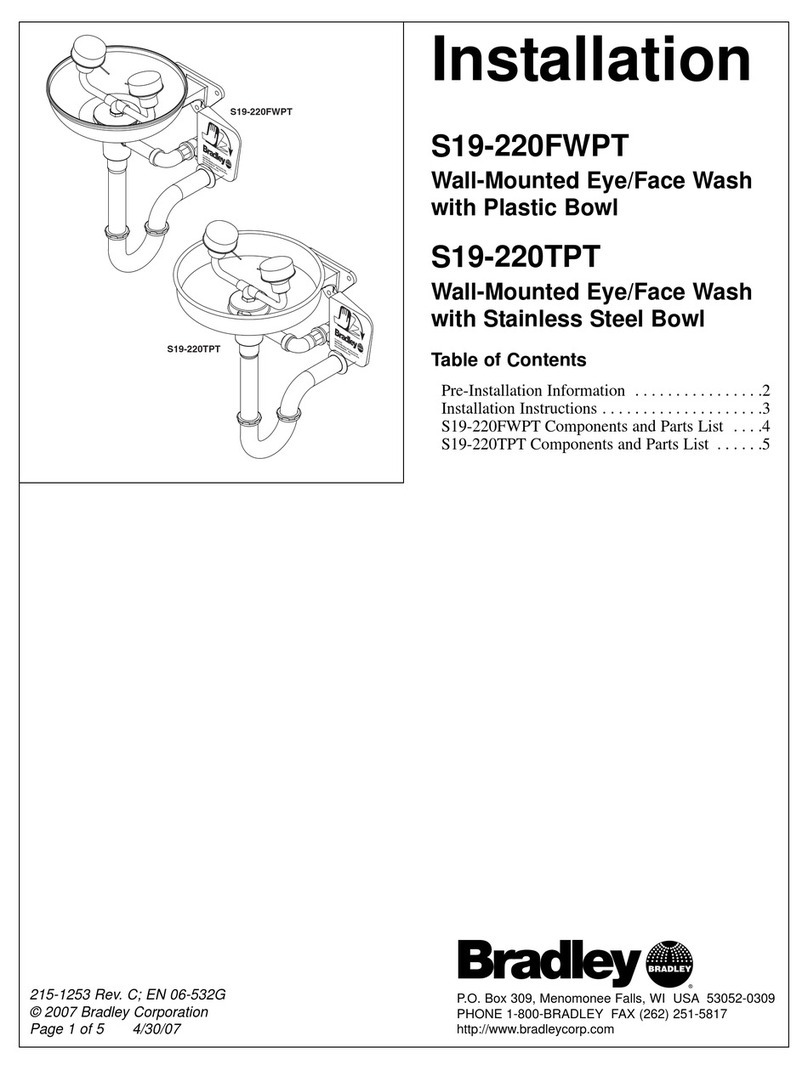

Bradley S19-220FWPT User manual

Bradley

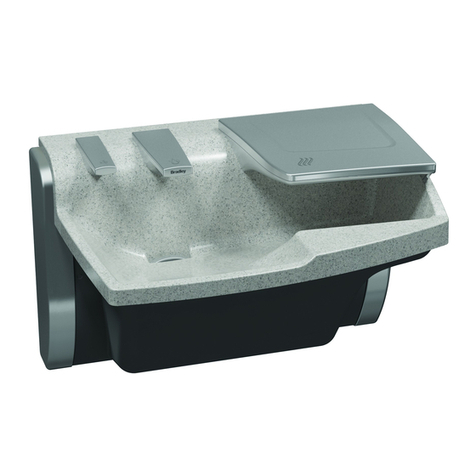

Bradley LC800 User manual

Bradley

Bradley WS-1X User manual

Bradley

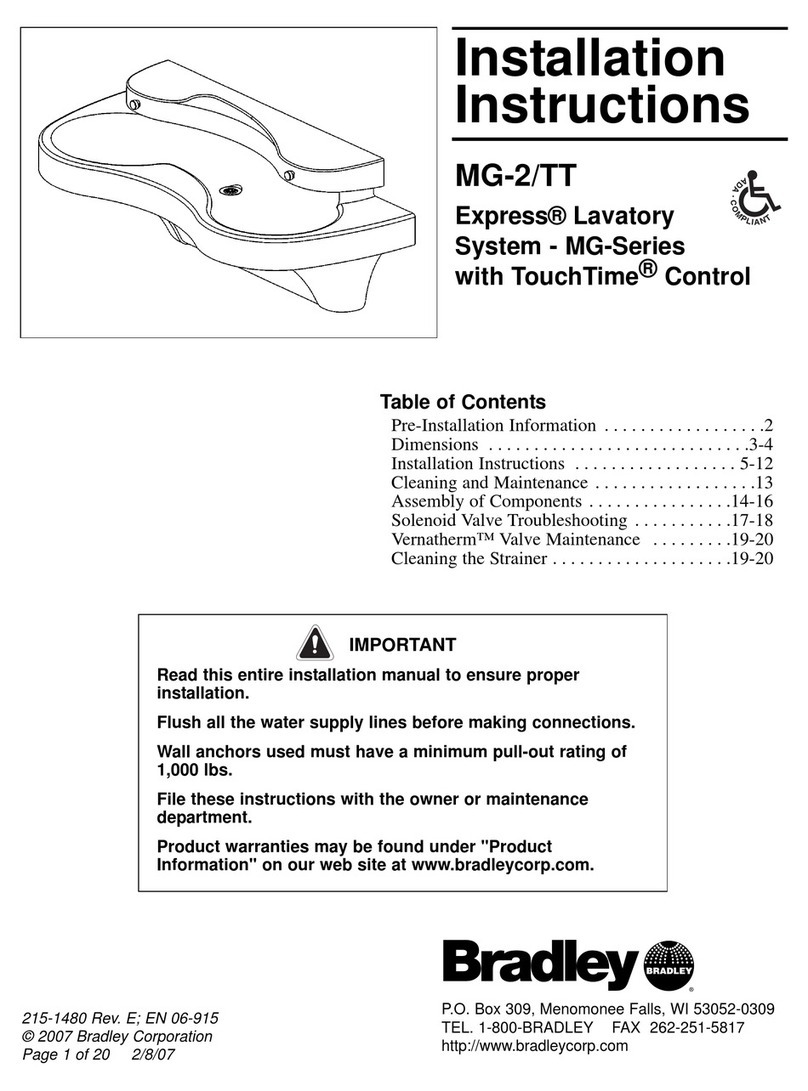

Bradley MG-2/TT User manual

Bradley

Bradley Verge LVRD Series User manual

Bradley

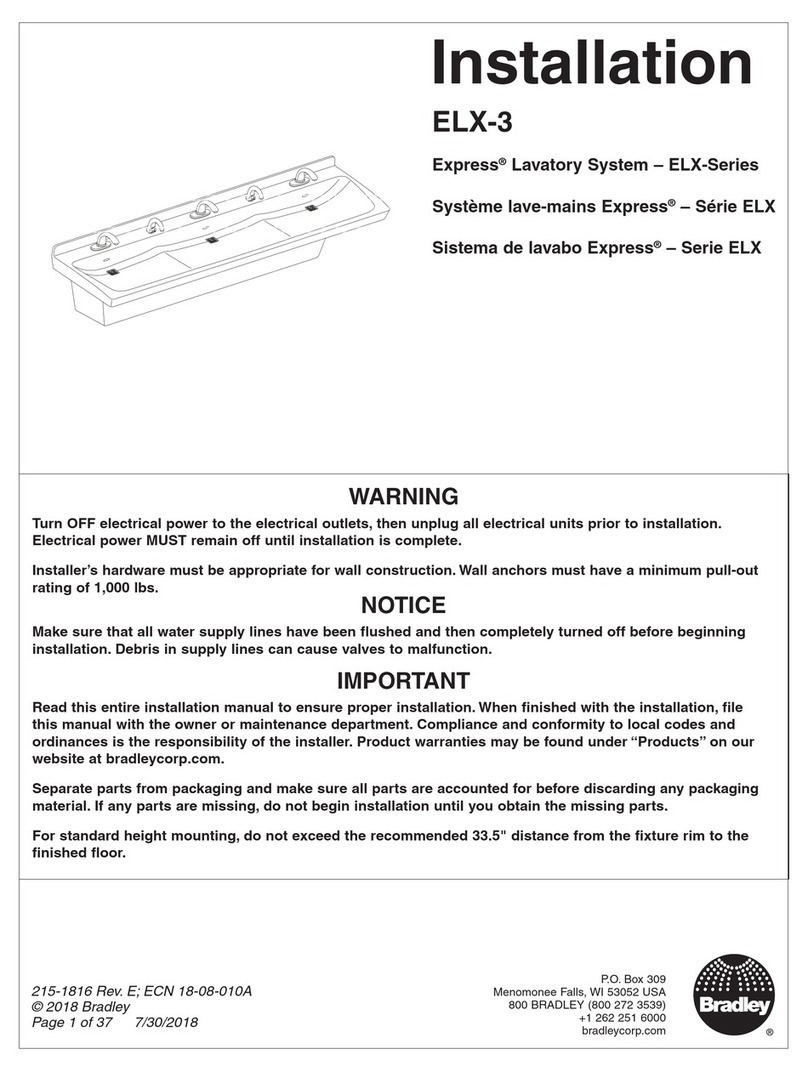

Bradley Express ELX-3 User manual

Bradley

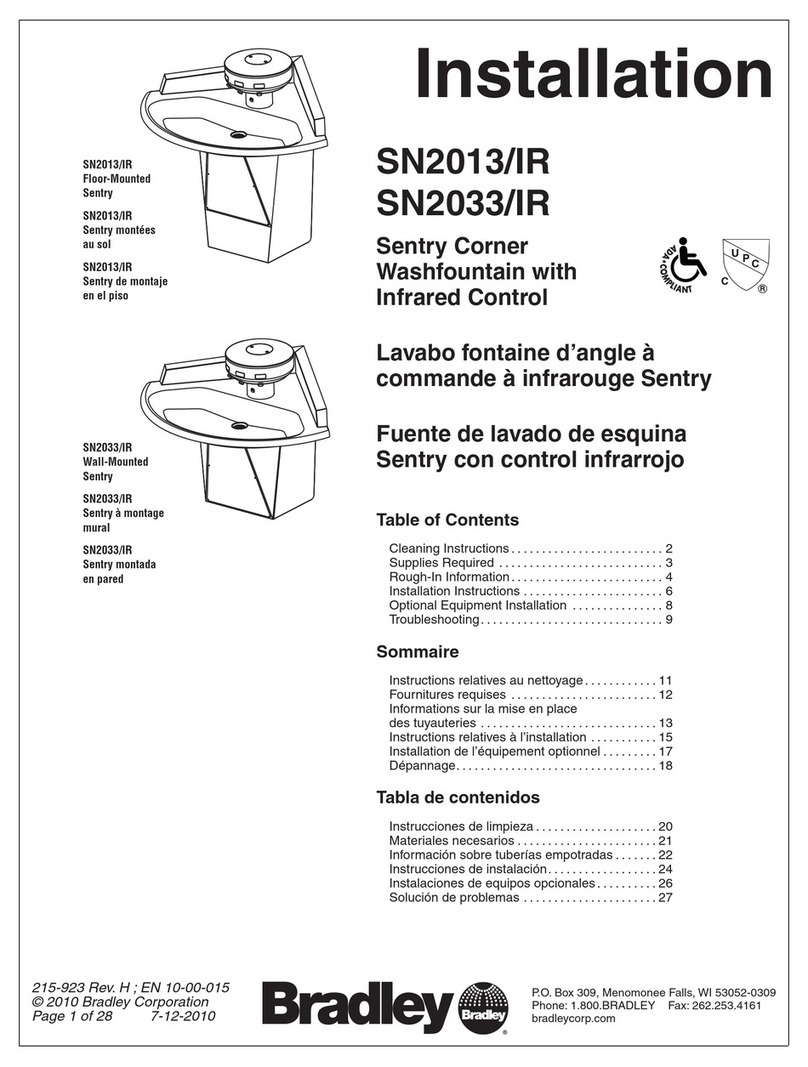

Bradley Sentry SN2013/IR User manual

Bradley

Bradley S19-210SC User manual

Bradley

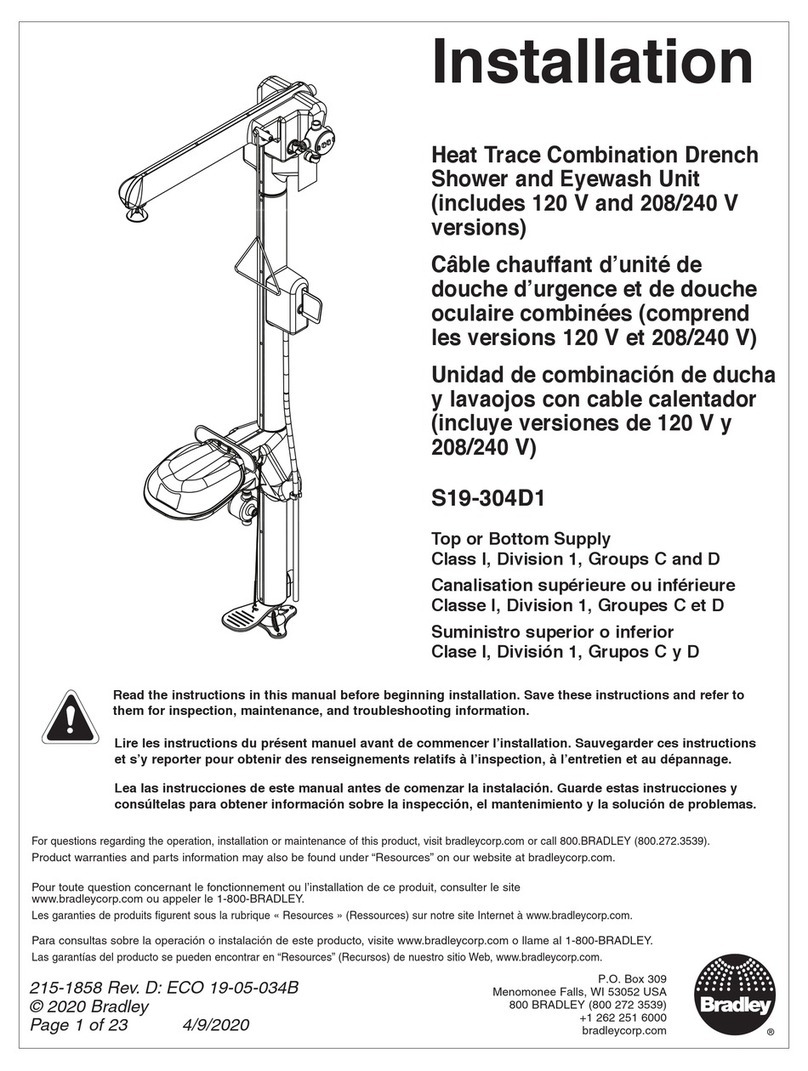

Bradley S19-304D1 User manual

Bradley

Bradley S19-270HD User manual

Bradley

Bradley Express ELX Series User manual

Bradley

Bradley Verge WashBar LVQ Series User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide