Contents.

Page

1.

Description

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

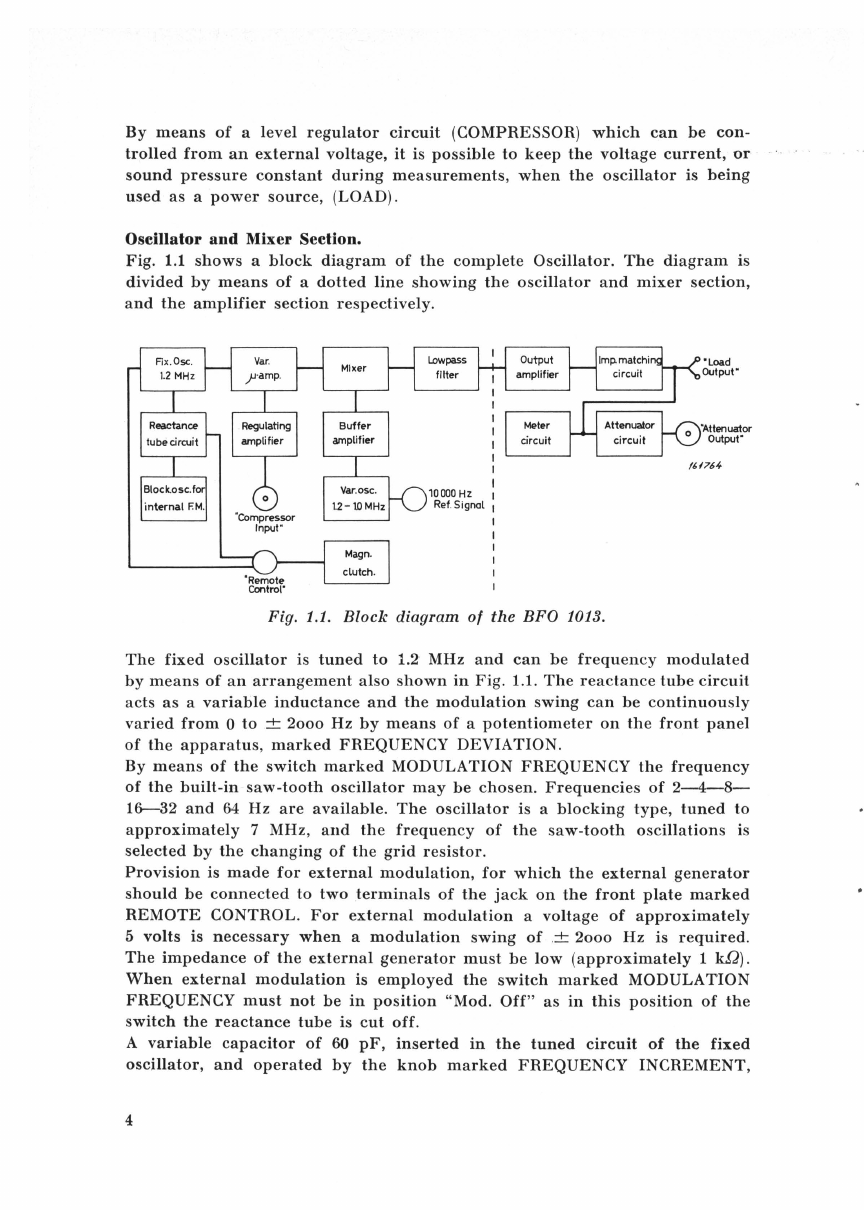

Oscillator

and

Mixer

Section

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Partial

Blocking

of

Frequency

Range

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Output

Amplifier

Section

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power

Supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.

Control

Knobs,

Terminals

and

Shafts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

3.

Operation

..............................

.

.........

.

....

..

.........

14

General

.....

.

...........................................

.

........

14

A.

Frequency

Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

B.

Operation

Using

the

Output

Terminals

marked

LOAD

............

15

C.

Operation

Using

the

Built-in

Output

Attenuator

..................

15

D.

Frequency

Modulation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

E.

Automatic

Recording

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

F.

Partial

Blocking

of

Frequency

Range

............................

19

G.

Automatic

Regulation

of

the

Output

Power

. . . . . . . . . . . . . . . . . . . . . .

21

H.

Remote

Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

I.

Trouble

Shooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.

Combined

Units

..

.

.............

..

.............................

.

..

24

Automatic

Frequency

Response

Recorder

Type

3306 . . . . . . . . . . . . . . . . . . 24

Automatic

Frequency

Response

Recorder

Type

3328

............

.

.....

25

5.

Applications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Electronic Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frequency

Response

Measurements

of

Four

Terminal

Networks

......

28

AC

Bridge

Measurements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Automatic

Recording

of

Electrical

Impedance

....

.

.................

30

Frequency

Response

of

High

Quality

Amplifiers

. . . . . . . . . . . . . . . . . . . . 31

Acoustical Measurements

.........

. . .

..............................

32

Frequency

Response

of

Loudspeakers

(Tweeter) . . . . . . . . . . . . . . . . . . . . 32

Directional

Characteristics

of

Loudspeakers

. . . . . . . . . . . . . . . . . . . . . . . . 34

Recording

of

the

Frequency

Response

of

Sound

Projectors

..........

35

Directional

Characteristics

of

Projectors

................

.

...........

36

Recording

of

Frequency

Response

of

Hydrophones

.

.................

39

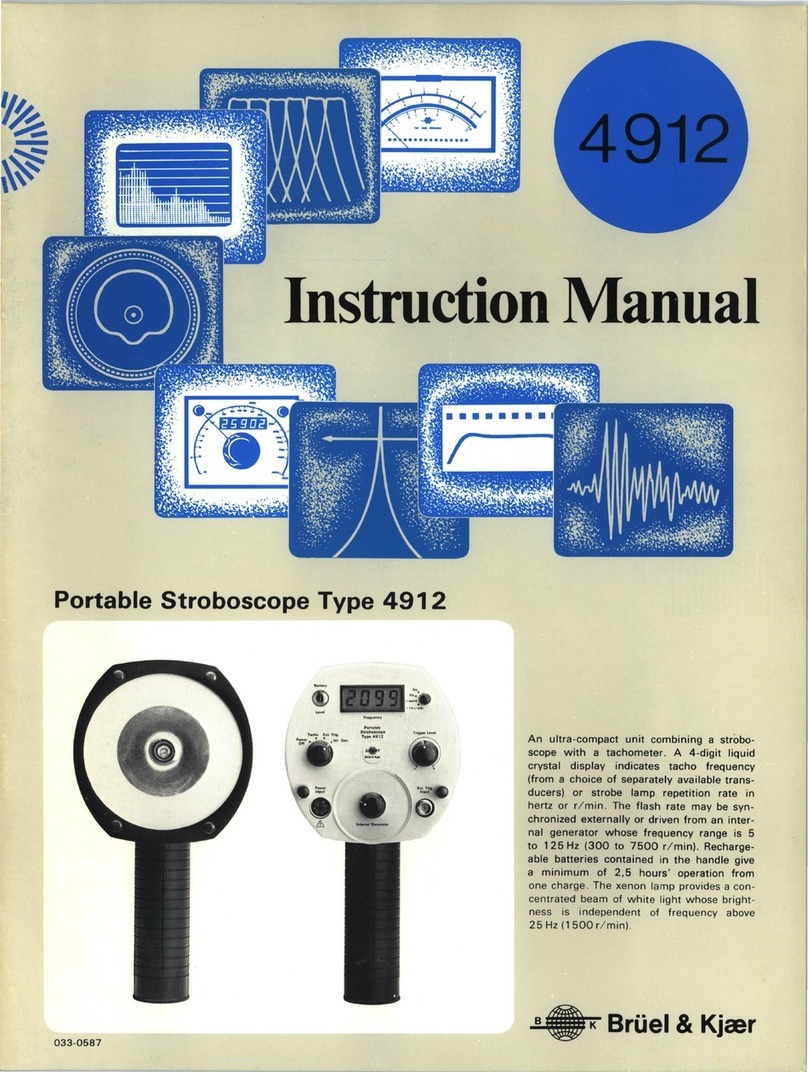

Mechanical Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Automatic

Recording

of

Accelerometer

Frequency

Response

. . . . . . . . . . 40

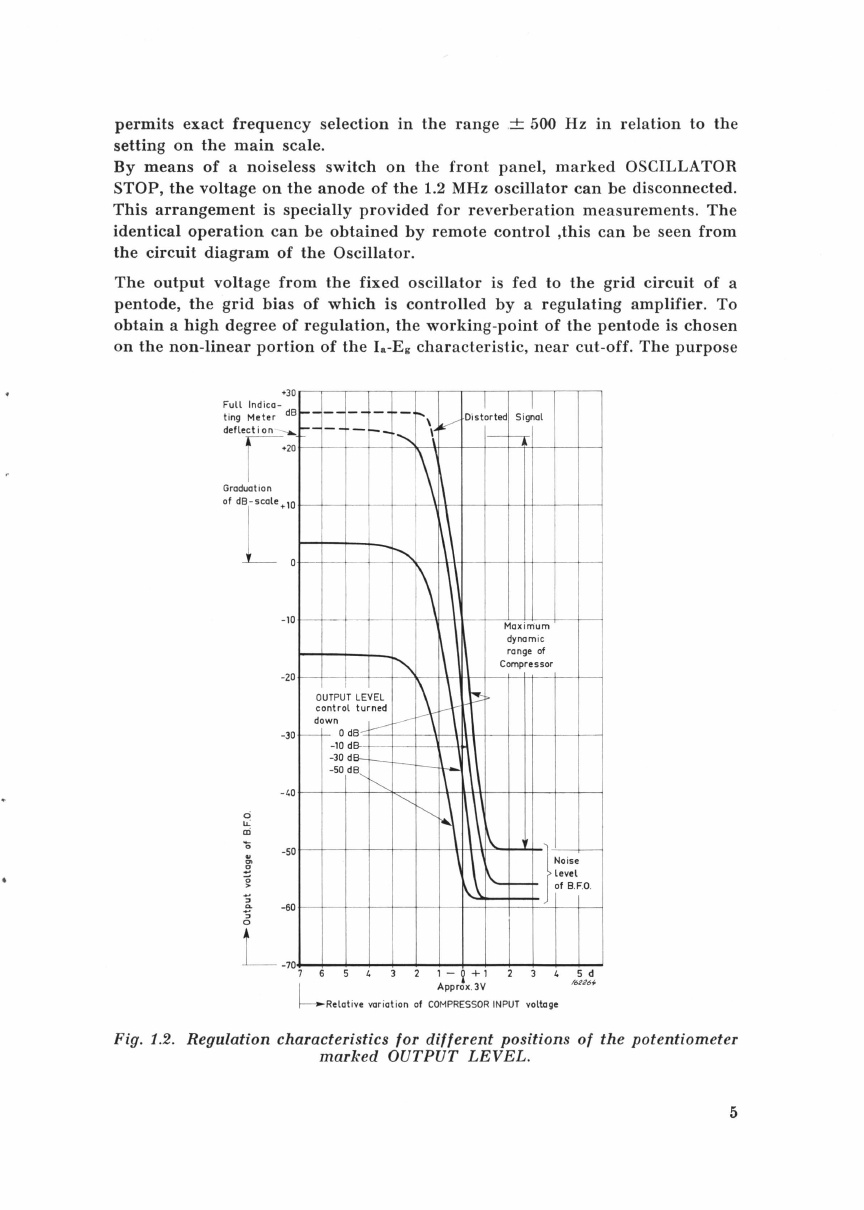

6.

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42