CONTENTS

1.

INTRODUCTION

......

.

.............

..

...........

............ .. .......

..

.....

.

......

..

:................

...........................

5

2.

INSTALLATION

...........................

....

.

.......

.

........................

..........

......

...

.................................

7

2.1.

MECHANICAL

INSTALLATION

OF

EXCITERS USING

TYPE

4801

BODY .....

.............

...........

..............

.........

......

.........

........

......

7

Direct

Mounting

..

.............

.......

..

......

..

.....

.........

..

........

....

....

.............

......

7

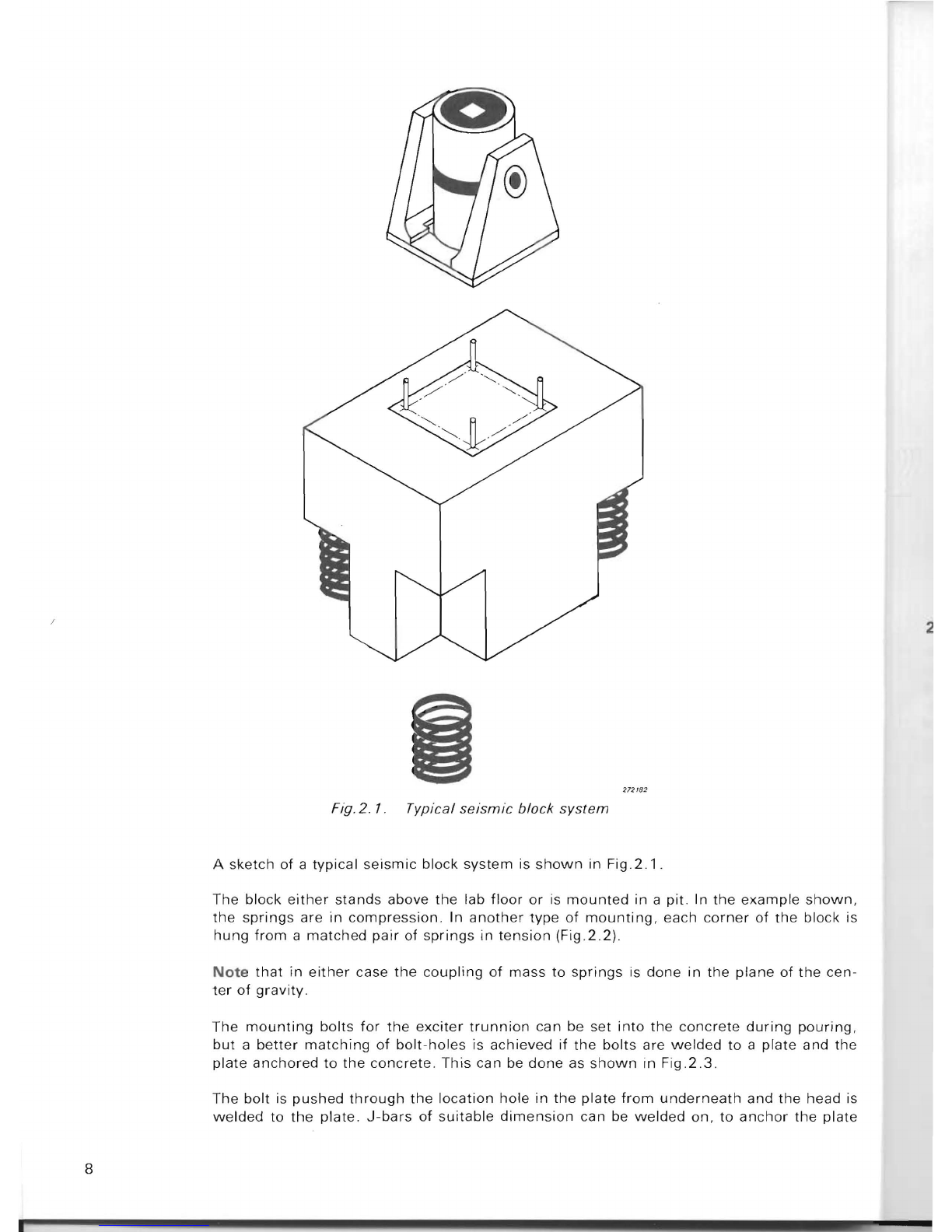

Mounting

upon a

seismic

block................

............

..

.....

.. ..

.. ...

.....

...

.....

....

.. ..

7

2.2

. ELECTRICAL INSTALLATION OF EXCITERS USING

TYPE

4801

BODY

..........

..

................

......

..

................

..

..........

..... ..

...........

9

System

Interconnection

......

......

.

.........

..

..

........................

....

........

.. .....

.....

..

10

Fan

Motor

Fuses ..

..

...............

..

.......................

...

.......

....

......

..

.....

.......

.......

10

2 .3 . INSTALLATION

OF

EXCITERS USING

TYPE

4805

BODY

.................................................

....

...............

.. .. ..

12

3.

OPERATION

.....

..........

......

....

.

..........

.........

....

..........

..

......

.......................

.................

..

..

.....

....

13

3.1. PRINCIPLE

OF

OPERATIOI\J

.......

..

........

.....................

....

.....

..

..

..... .....

......

...

13

3.2

. SELECTION

OF

APPROPRIATE B & K EXCITER HEAD

...............

... ..

..

.........

13

Brief

Description

...........

...............................

.. .. ..

........

.........

......

..............

14

3.3.

MOUNTING

AND

REMOVAL

OF

EXCITER HEAD ...

..

...........

....

.. ..

............

..

..

15

4801

Body .

..............

.....

...........

......

......................

.......... ..............

..

........

15

4805

Body

...........................

...........

............

......

.............

.....................

16

3.4

. INSERT INSTALLATION

AND

REPLACEMENT

...

..

..........

.

............

.

..

.

......

16

3.5. FIXTURES

.......................................

..

......... .....

..

..

..............

..

.. .. ....

16

3.6.

MOUNTING

THE FIXTURE

AND

TEST OBJECT .............

..

.. .. .

.. ..

........

.. ........

..

17

Bolt

Patterns

and

Mounting

Screws

...

............

.....

.. .....

....

.......

....

..

.....

.........

17

Positioning

the

test

object

.......................................

..

..

.........

......

..

....

.. .

18

Externai

Supports

...............

.. ....

...............

....

.. ..

................

....

......

..........

.. ..

18

Electrical

connections

to

test

objects .

.......

...

..

.........

..

...........

.. ...

......

.

..........

19

3.7. POSITIONING THE EXCITER ....

...........

..

....

.. ...............

........

........

..

..............

19

3.8

. STATIC

LOAD

LIMITATIONS

.......

....

......

...

............

..

....

.

.......

.....

......

........

..

..

20

3.9.

PUSH RODS

.............................

.. ..... ....

.....

....

..............................

......

......

23

3.10.

START-UP PROCEDURE ...

........

...... .......

.......

.. .......

..

....... .....

........

.

......

....

24

3.11.

"EXCITER"

LAMP

INDICATION

...........................

...

.....

..

....

.

......

.

......

.. ..

..

....

25

3.12

. OPERATION

IN

HIGH

AMBIENT

TEMPERATURES ...

..........

..

......

................

25

4801

Body

.....

....

...............

.....

..

.... ....

.............

...... .

..........

........

........

25

4805

Body

........

..................................

.

.............

....

........

..

......

.. ...

....

......

25

3.

13.

REDUCTION

OF

RESIDUAL MOTION

.....

...

..........

.

....

...

.......

.

.............

..

....

.. . .

25

4.

DESCRIPTlON

OF

4801

EXCITER

BODy

...........

..

................

.....

...

....

.....

..............

......

...........

26

4.1.

THE

MAGNET

ASSEMBLy

..................

..

......

.. ..

....

......

.....

...

.....

....

.. ... ..

.....

...

27

Field Coils ....

..

..........................

..

............................

.......

..

........

.

..

...

....

...

..

27

Secondary

Bands

.. ......

..

... .

.. ..

.......... ..........

..

..

..

..

............

......

.. .. ..

....

..

........

27

Stem

............

.

..........

.. .. .

.....

..

..

.......

..

..

.......

...........

................

..

..

.

.............

27

Centre

Bowl

.. .

..

.............

.......

........

..............

......

..

...................

..

...............

27

Upper

Wheel

............

..

....

........

..........

.......

... ....

.....

......

.....

..................... ...

27