Bruker D8 Discover Manual

Other Bruker Laboratory Equipment manuals

Bruker

Bruker AVANCE User manual

Bruker

Bruker NMR CryoFIT User manual

Bruker

Bruker NMR 400 89 Ascend DNP User manual

Bruker

Bruker DektakXT User manual

Bruker

Bruker Ascend 400'54 User manual

Bruker

Bruker AVANCE NEO User manual

Bruker

Bruker NMR 600'89 Ascend DNP User manual

Bruker

Bruker CryoProbe User manual

Bruker

Bruker Ascend 400'54 User manual

Bruker

Bruker CryoProbe User manual

Bruker

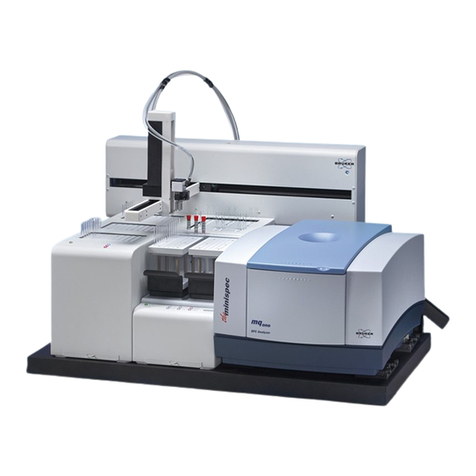

Bruker minispec User manual

Bruker

Bruker SampleXpress User manual

Bruker

Bruker 600'54 Ascend ULH User manual

Bruker

Bruker Ascend 600'89 User manual

Bruker

Bruker 300'154 Ascend DNP User manual

Bruker

Bruker DektakXT User manual

Bruker

Bruker Ascend 750'89 User manual

Bruker

Bruker D8 Series User manual

Bruker

Bruker 300'89 Ascend User manual

Bruker

Bruker BioSpin NMR CASE User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual