Parameter scale: Use this screen to set the maximum

range for boost pressure and various temperature slide

bars and graphs.

Example: You will be running a 30 psi boost target. The

max boost pressure could be 35 psi to give the slide bars

and graphs the best resolution. The same goes for

temperatures. These values should be entered with

respect to which units are selected: SI or SAE. If SI units

are selected, Boost Pressure should be entered in kPa

and temps should be entered in Celsius. If SAE units are

selected, Boost Pressure should be entered in psi and temps in Fahrenheit.

Shift Light Configuration:

Touch the gear that you wish to change the shift light

RPM on. That gear number will appear above the up and

down arrows for verification. Use the up and down arrows

to adjust the shift light RPM set-point of said gear. Press

the back arrow button at the bottom right hand corner to

save the settings. The shift light should flash once the

settings are saved.

Base Fuel Pressure configuration:

In order to calculate the base fuel pressure, the engine

should be idling. Press the CALCULATE button and the

base pressure will be calculated and displayed. This is

used on the fuel screen in order to graph the fuel

pressure vs. boost pressure for simple regulator function

verification.

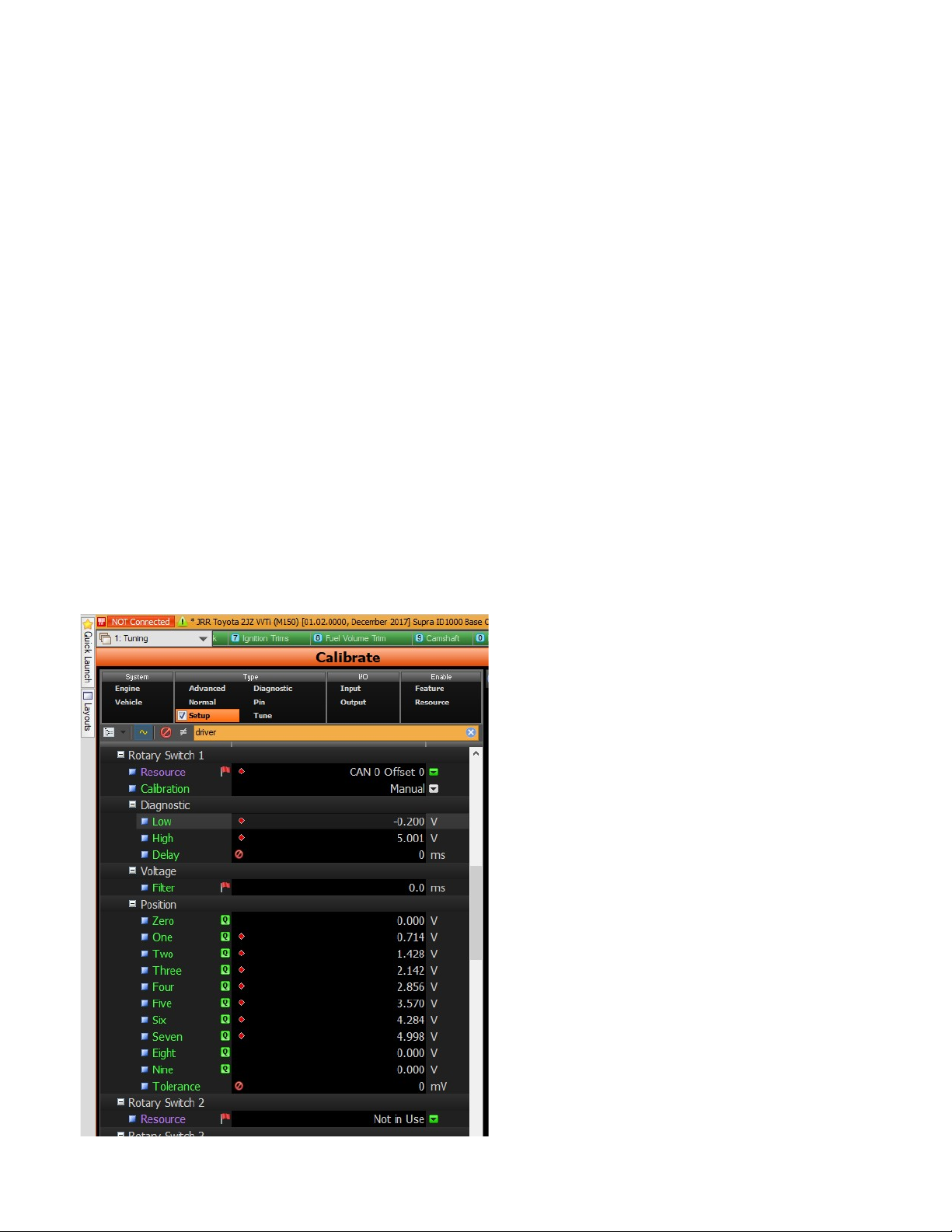

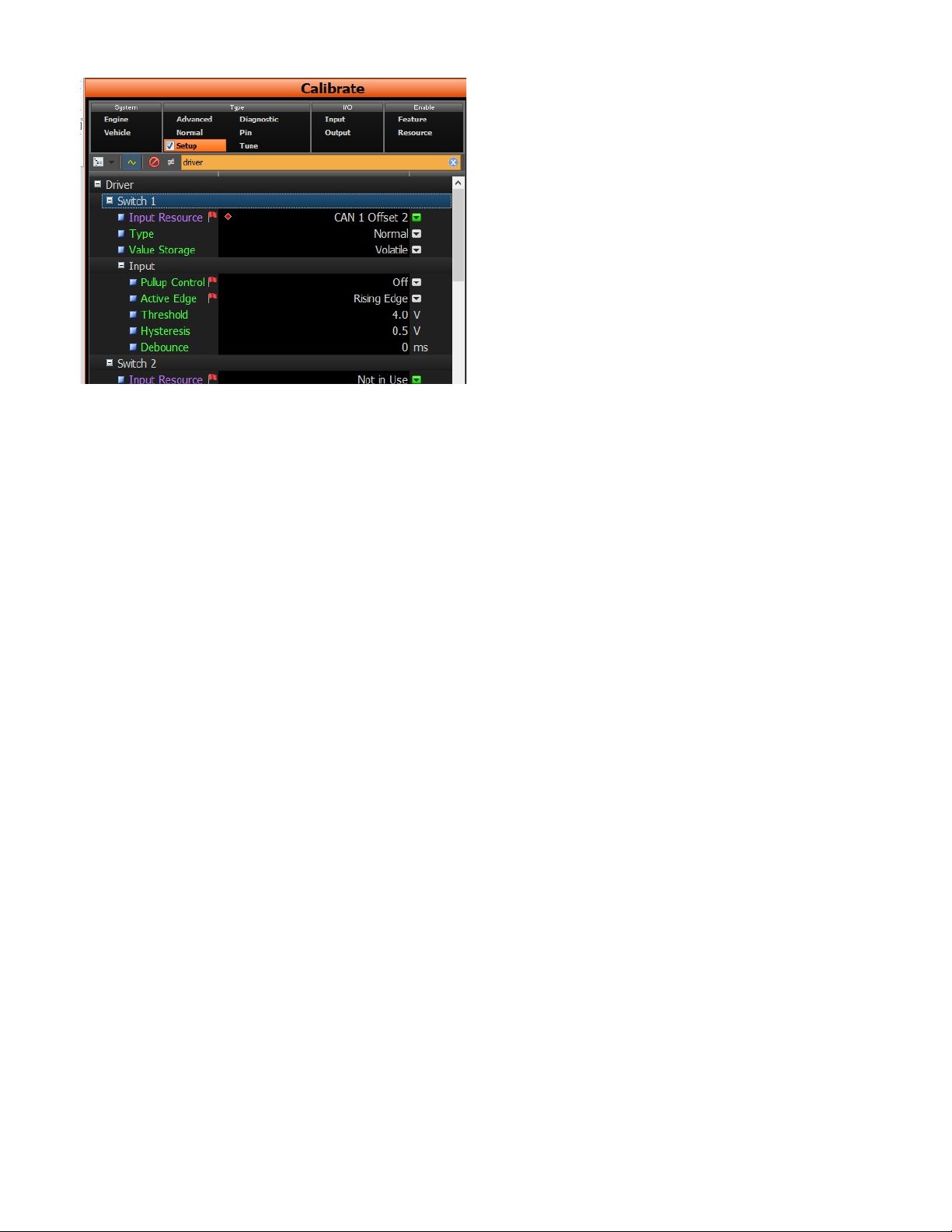

TRAC and BOOST PWM Steps:

Use these two buttons to configure how many steps are to

be programmed in the Infinity Tuner software for Boost

and Slip. Typically the scale is from 0-5 volts and the max

amount of steps allowed is 7 which give you 8 settings (0-

7). Example: a value of 7 here would make each step

would have a value of .71 volts. A value of 1 here would

give the step a value of 5 volts. It is imperative to view

each step in the M1 Tuner software when configuring this

as there could be a potential difference with regard to