BathyCorrometer Calibration Kit

4

Screw Threaded tie

Bath

Corromete

®Pro’ Bod

Electronics Calibration Check

1. The electronics in the BCM/BCM Pro’ can be checked with the aid of

the CalChecker Pro’. When connected to the BCM/BCM Pro’, this

produces a precision voltage of -1.900V DC which can be compared

with the reading on the BCM/BCM Pro’. This is just a check as the

electronics are contained inside the pressure housing and cannot be

adjusted without breaking the seal.

2. If the BCM/BCM Pro’ is more than ± 2mV out from the -1.900V test

voltage, firstly check the battery in the CalChecker Pro’. If necessary,

replace with a CR1632 standard lithium primary button cell (1002-0026).

Then ensure the CalChecker Pro’ is not at fault. This can be carried out

using a calibrated precision multimeter. If the CalChecker Pro’ is within

specification, it is advised that the BCM/BCM Pro’ should be returned to

the manufacturer or certified test house for repair.

3. The warranty will be void if repairs are undertaken by anyone other than

the manufacturer or a certified test house.

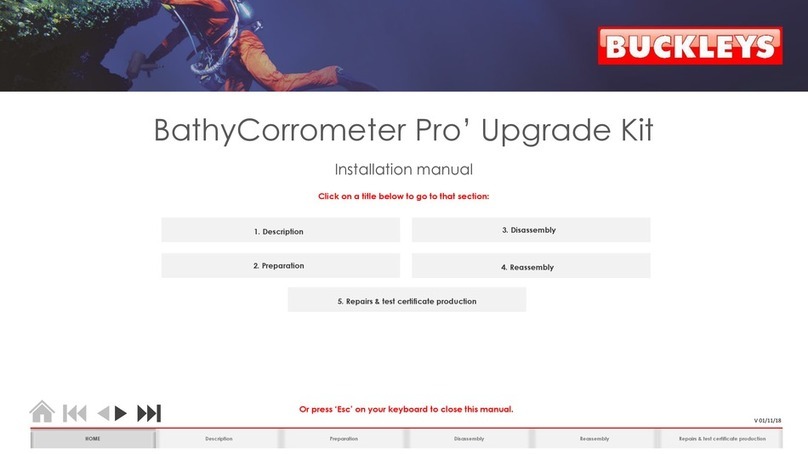

Test procedure using screw-on K-Sat reference electrodes

1. Unscrew the white Delrin probe cone.

2. Smear the O-ring on the K-SAT reference

electrode with a little silicone grease.

3. Screw the K-SAT reference electrode onto

the threaded tie Rod, ensuring a tight connection

and correct seating of the O-ring. Unscrew the

K-SAT end cap to remove it.

4. Fit the shorting plug (6004-0019) and immerse the BCM/BCM Pro’ in

seawater test solution (3% salinity), ensuring that the level covers the red

Note: If checkin

the calibration of an older BCM, connect the short lead

between the CalChecker Pro’ and the BCM’s stainless steel probe tip.