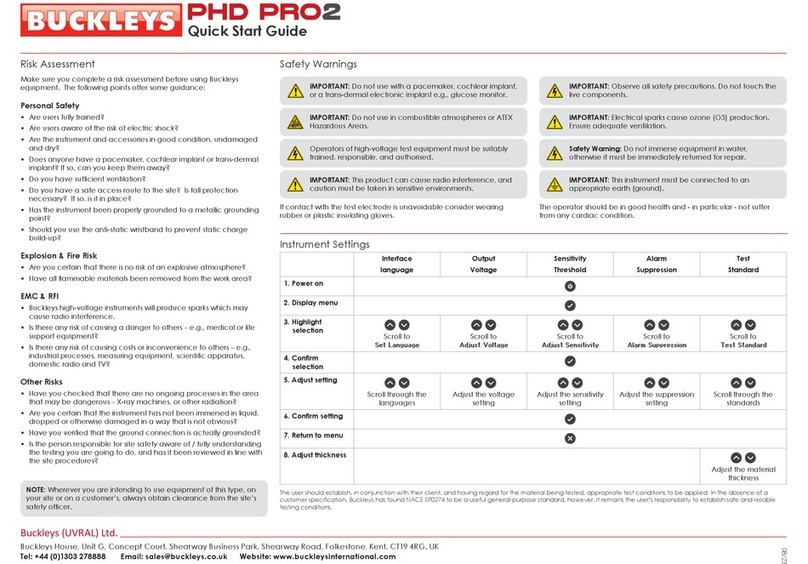

The PST-100 Spark Tester is intended to generate a high voltage

discharge, it is only to be used by responsible and authorised personnel

that have read and understood this manual.

The probe must NEVER be directed at the body.

There is a potential risk to those who might have an incipient heart

condition.

There is also a potential risk from the reflex action when receiving a high-

voltage shock. Injury could also occur if the spark were discharged to

sensitive parts of the body (e.g. eyes).

In a reasonably ventilated room of a volume greater than 40m3, the

exposure to ozone produced by the high voltage spark should not

present a risk to health. In a ‘confined space’ situation it is likely that

ozone levels will exceed the exposure limit and present some risk to

health. Under these conditions adequate ventilation must be provided.

WARNING: This equipment must not be used in

any combustible atmosphere; the high voltage

discharge will cause a spark from which an

explosion could result.

WARNING: This equipment must not be exposed to damp or

wet conditions, or where the amount of conductive dust is

greater than would occur in a normal situation.

WARNING: Never connect or disconnect the electrode

with the PST-100 connected to the mains supply.

IMPORTANT: We strongly advise that individuals with

pacemakers do not use our high-voltage test equipment

under any circumstances.

Misuse or failure to comply with the guidelines outlined in this manual

may impair the safety provided by the equipment.