Electromagnetic compatibility

Electromagnetic Emissions - European Union Directive:

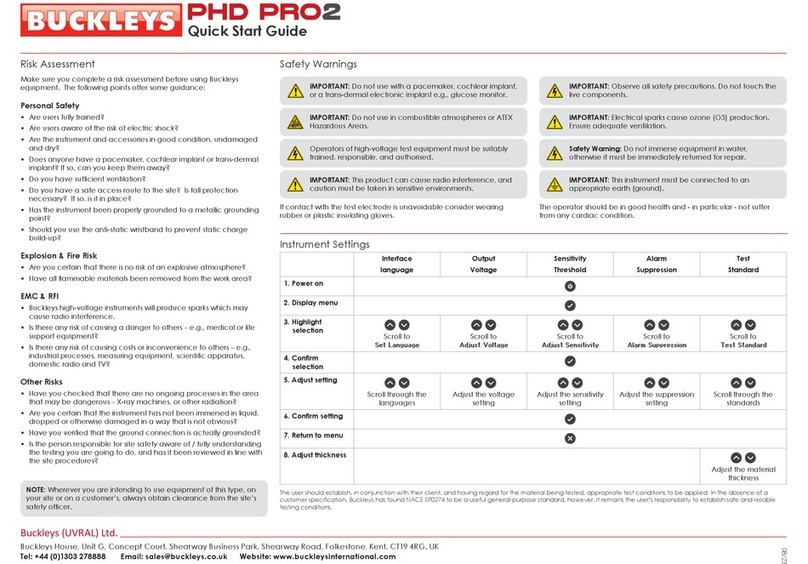

Before operating this equipment it is essential that the following action be taken.

Risk assessment

As this equipment will produce an electromagnetic emission, when actually arcing down

through a fault to earth, a risk assessment of the area in which the unit will be used should

be carried out. For example, the equipment should not be operated where the

electromagnetic disturbance generated may hinder the operation of such apparatus as:

A Domestic radio and television receivers.

B Industrial manufacturing equipment.

C Mobile radio equipment.

D Mobile radio and commercial radiotelephone equipment.

E Medical and scientific apparatus.

F Information technology equipment.

G Domestic appliances and household electronic equipment.

H Aeronautical and marine radio apparatus.

I Educational electronic equipment.

J Telecommunication’s networks and apparatus.

K Radio and television broadcast transmitters.

L Lights and fluorescent lamps.

The Directive also requires the above types of equipment to have an adequate level of

electromagnetic immunity from such emissions. However, it should be borne in mind, when

doing an assessment, that the directive applies to equipment supplied or taken into

service after the 1st January 1996. The equipment you are assessing, although legal but

because of age, may not have this immunity.

The more common areas of risk are computers, critical safety equipment on process or

machine tools (fail/safe electronics), supply cables, control cables, signalling and telephone

cables above, below and adjacent to the area where the tests are being carried out.

The wearers of pacemakers and hearing aids should also be considered. Measuring and

calibration equipment may also be susceptible.

To make a comparison; arc welders, when in use, would create interference far greater

than this type of tester. It would, therefore, be reasonable to assume that if an arc

welder had been used in the area, without problems, then an AC pinhole detector

would be safe. However, it would be unwise to use both pieces of equipment on the

same site at the same time as they may interfere with each other.

The test area itself should also be considered. For example, the layout of the area would

affect the distances which the emissions would travel. Buildings and metal structures

tend to shield against, or reduce, emissions. If the tester were being used inside a metal

tank, for instance, the tank would act as a very good shield. This would not, however,