ST-AC Pro’

9

Calculating the test voltage

The test voltage needs to be high enough to find the fault but not so high as to

make one. With reference to BS EN 60052:2002 (Measurement of Voltage with

Sphere-Gaps) it can be seen that 32,000 volts will jump a gap of 1cm between

spheres of 5cm diameter. The same voltage will jump a gap of nearly 3cm

between needles. This is because the shape of the electrode affects the point at

which corona discharge starts i.e. the sharper the points on the electrode the lower

the voltage necessary for corona discharge to start.

‘Spark-over’, or complete temporary breakdown of the air between the

electrodes, will occur when the voltage is increased to cause localised

breakdown. This soon spreads throughout the whole of the inter-electrode space

and generates the required number of ions to carry the current (this may be tens of

amperes). With this sudden increase in current there is a corresponding fall in the

voltage across the electrode to a very low level.

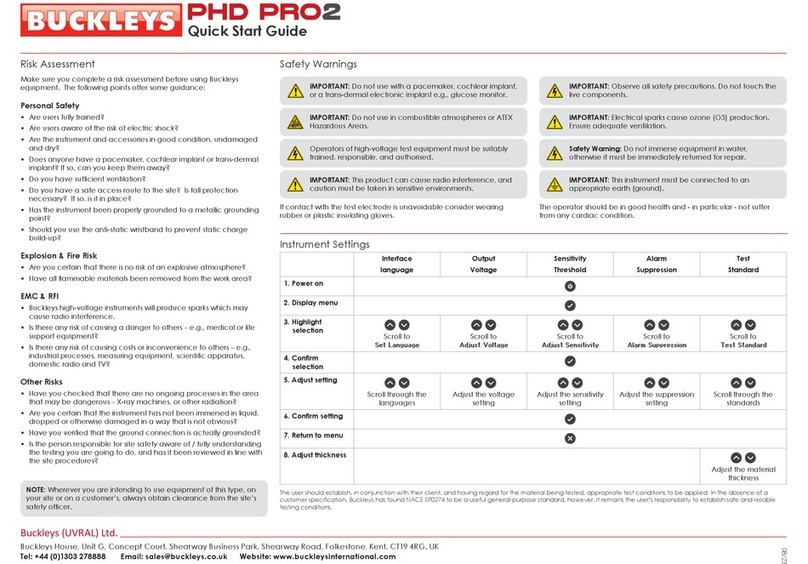

For the thicker types of material in the range 1mm to 30mm the formula used in the

NACE Standard SP-02-74 has been found to work well in most cases.

SP-02-74 test voltage formula

Alternatively

After the test voltage has been calculated, it is necessary to check that the

voltage is not so high as to damage the material under test. The dielectric strength

is the voltage at which the material starts to break down, this is expressed in volts

per mm, normally referring to DC.

To take an example, using the above formula, a 2mm thick sheet of PVC would

require a test voltage of at least 11,180 volts.

Referring to the plastic manufacturer’s technical data, the dielectric strength of

PVC is 8,400 volts per mm. 2mm x 8,400 =16,800V, so the test voltage is not

expected to damage the material.

If the dielectric strength of the material was only 5,000 volts per mm, then the test

voltage would be too high, and this may result in damage to the part under test. In