Safety instructions

5

2 Safety instructions

2.1 Potential hazards

Danger!

Never point the operation-ready device at people.

Danger from high pressure!

Burn Hazard

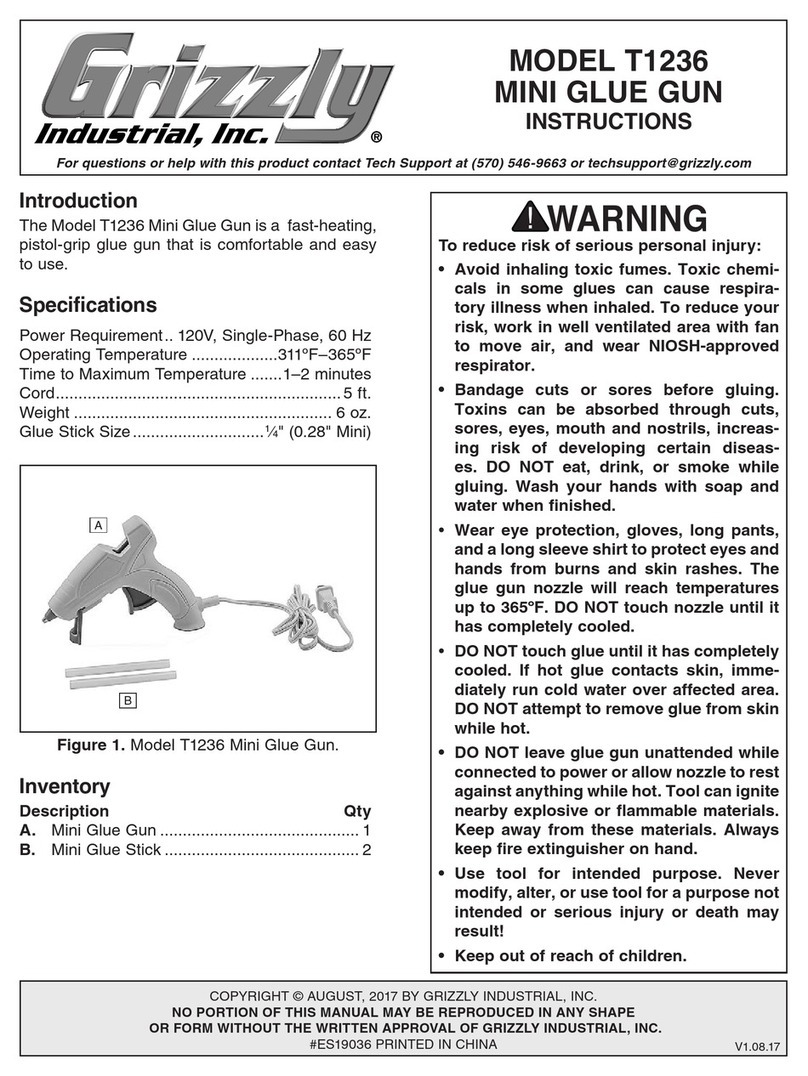

Nozzle (1) and molten adhesive can be over 392° F (200° C) hot.

Wear heat-resistant gloves if contact is unavoidable.

Risk of Explosion!

When working with oxygen or combustible gases there is risk of explosion!

Xi Odor nuisance!

Hot-melt adhesives give off fumes which can cause odour nuisance – so ensure

adequate ventilation.

Improper use may in isolated cases lead to irritation of the mucous membrane. In this

case seek immediate medical advice!

2.2 Instructions for safe operation

Guard against malfunctions and operating errors by always following these instructions

precisely:

• In no circumstances may the maximum permitted operating pressure (87 psi, 6 bar) be

exceeded.

• Remove combustible or heat-sensitive objects from the area of the nozzle.

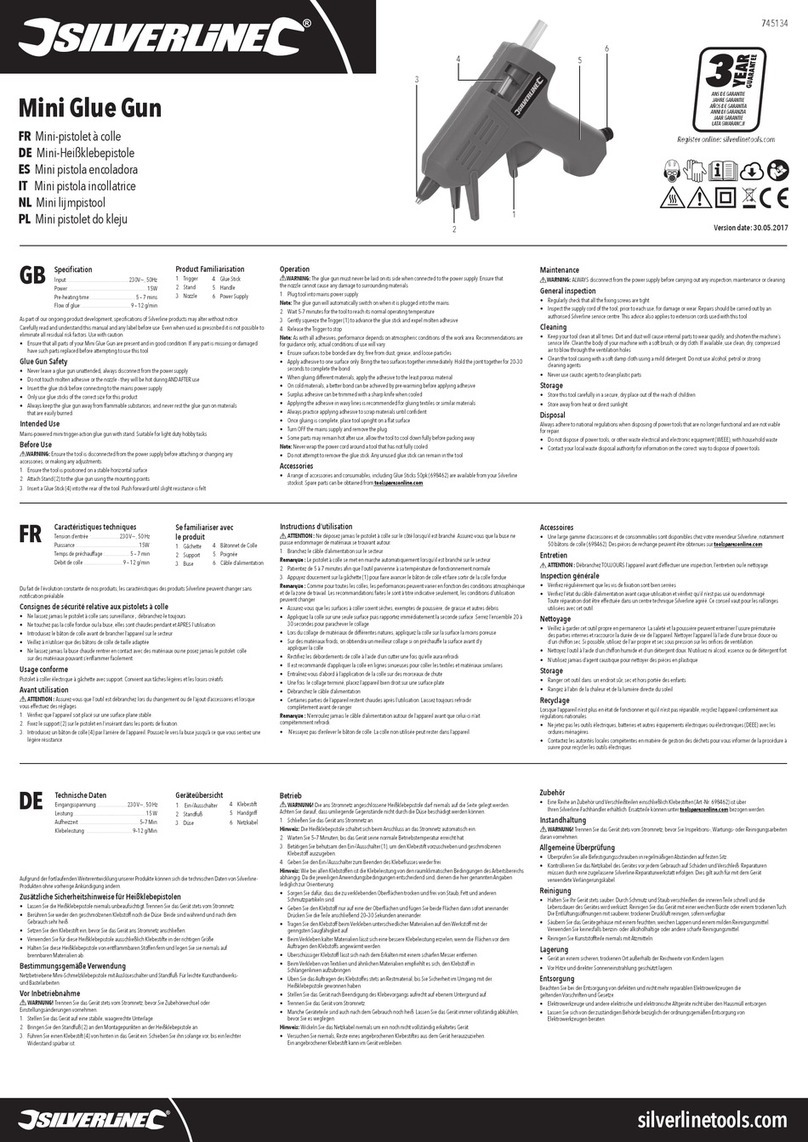

• When warm the device must be put down on the stand foot (8) or, alternatively on the

working console (see section 11, Accessories). It must not be laid on its side.

Otherwise melt may escape uncontrolled through the vent holes and present a burn

hazard.

• Never operate the trigger (6) forcibly.

• Protect the device from moisture and damp (protection against electric shock).

• Observe the instruction leaet for the hot-melt adhesive (protection against processing

errors).

• Operate the device only with the nozzle pointing downwards. It must not be operated

above head height!

• Unplug from the mains before performing any operation on the device (servicing,

cleaning).

• The device must be powered only from sockets with a protective conductor.

• Any extension cable used must have a protective conductor. Check that the protective

conductor is undamaged before use.

• Unplug from the mains after each use. Allow the device to cool down completely before

putting it away.

• If you notice any damage to the device or leads, unplug from the mains immediately.

Have the device promptly checked over by an expert. It must not be used again until it

has been properly repaired (see Sections 6 and 7).

USA