ENGLISH

ENGLISH

4.3.5 Version with PNP transistor output via M12 connector ..................................................................16

4.3.6 Version with relay output ...........................................................................................................................................16

4.3.7 Version with relay and frequency outputs ....................................................................................................17

5.1 General recommendations .....................................................................................................................................................18

5.2 Functionalities ...................................................................................................................................................................................18

5.3 Programming keys ........................................................................................................................................................................19

5.4 Default Configuration ..................................................................................................................................................................19

5.5 Normal Mode .....................................................................................................................................................................................20

5.6 Possible switching modes of the 8039 .......................................................................................................................21

5.7 Calibration Mode .............................................................................................................................................................................22

5.8 Simulation Mode .............................................................................................................................................................................25

6.1 Cleaning .................................................................................................................................................................................................26

6.2 Error messages ................................................................................................................................................................................26

6.3 When a problem occurs ............................................................................................................................................................27

7.1 Connection examples with a 8039..................................................................................................................................28

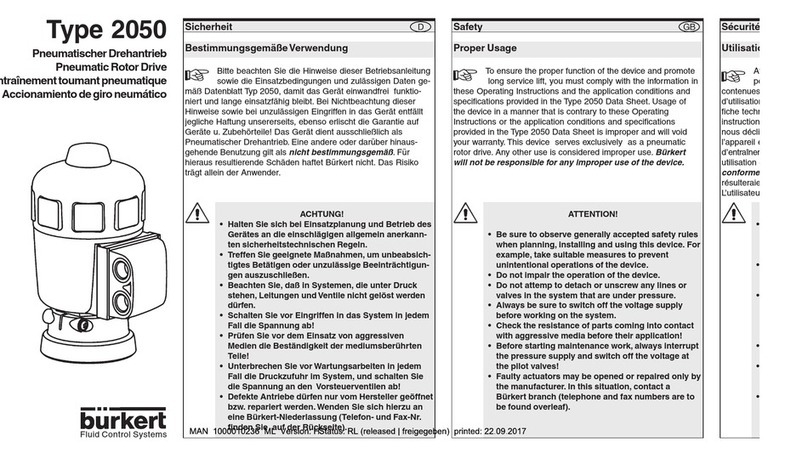

7.2 Description of the label of controller 8039...............................................................................................................31

7.3 Flow rate-velocity-DN diagrams .........................................................................................................................................32