5

Intended use

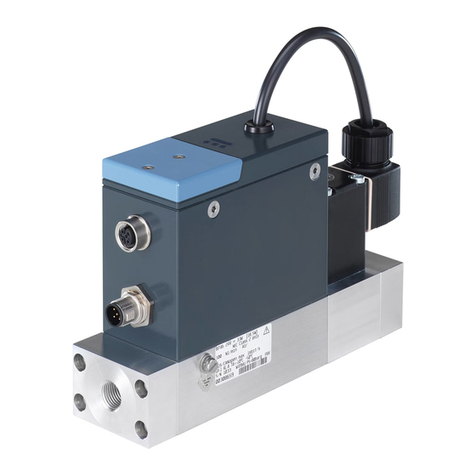

Type 8045

2. INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

The insertion electromagnetic flowmeter type 8045 is intended

exclusively to measure flow rate in liquids.

▶This device must be used in compliance with the characteristics

and commissioning and use conditions specified in the contrac-

tual documents and in these Operating Instructions.

▶Never use this device for security applications.

▶This device must be protected against electromagnetic interfer-

ence, ultraviolet rays and, when installed outdoors, the effects of

climatic conditions.

▶Only operate a device in perfect working order.

▶Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

▶Only use the device as intended.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurrences that may arise during instal-

lation, use and maintenance of the devices.

• the local safety regulations for which the operating company is respon-

sible including the staff in charge of installation and maintenance.

Risk of injury due to high pressure in the installation.

▶Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Danger due to electrical voltage.

▶If a 18...36 V DC powered version is installed either in a wet environ-

ment or outdoors, all the electrical voltages must be of max. 35 V DC.

▶Disconnect the electrical power for all the conductors and isolate

it before carrying out work on the system.

▶Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Risk of injury due to high fluid temperatures.

▶Use safety gloves to handle the device.

▶Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

▶Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

English