2

Table of Contents

Safety Instructions......................................................................4

Qualifications of installer and operator...............................................................................................4

Generally Safety instructions .............................................................................................................4

General Information...................................................................5

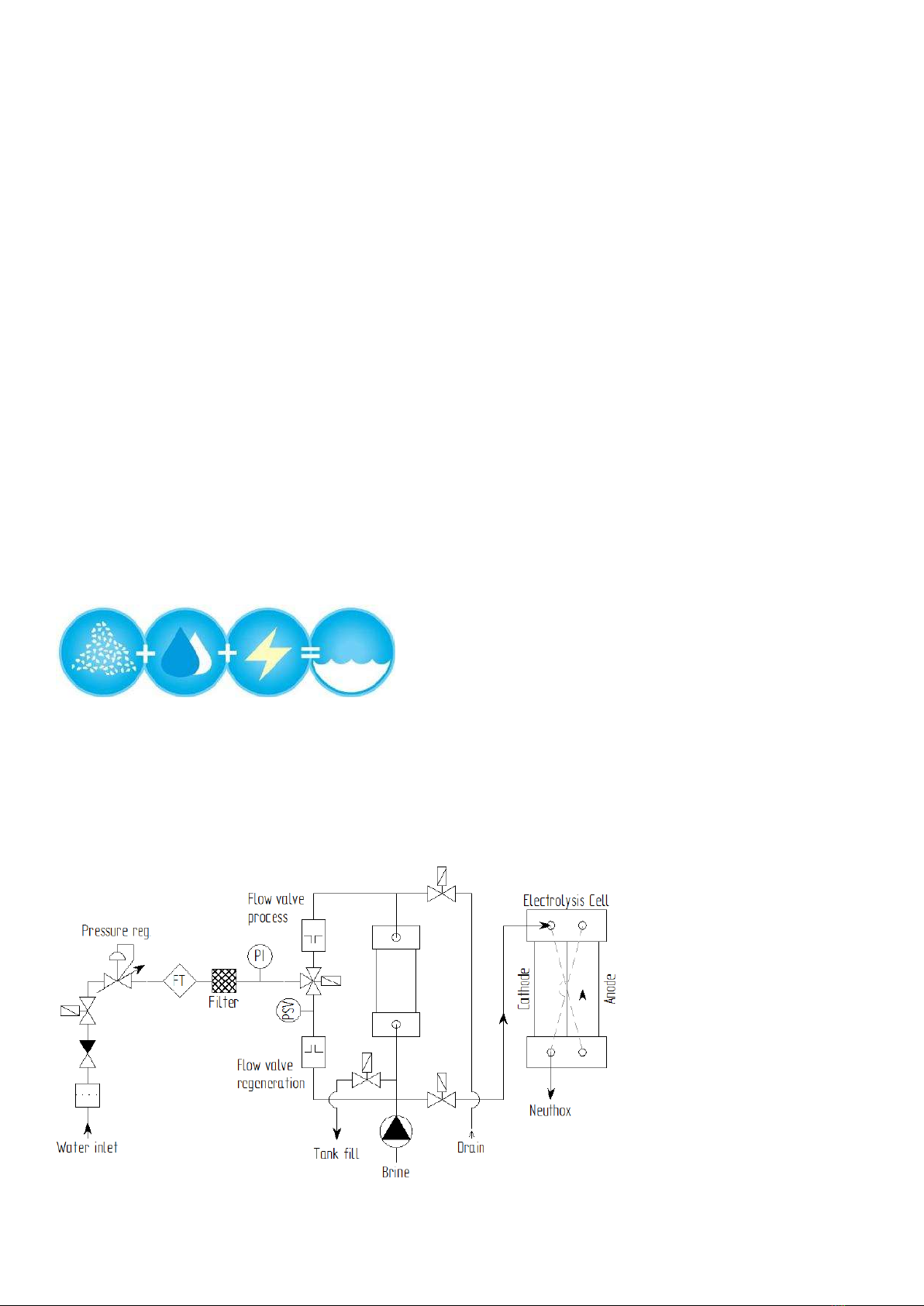

Neuthox .........................................................................................................................................5

The BWT Disinfection .......................................................................................................................5

Application .....................................................................................................................................6

Improper Operating Methods............................................................................................................7

Warranty........................................................................................................................................7

Nameplate......................................................................................................................................7

Type Key ........................................................................................................................................8

Product overview.......................................................................9

Electrical cabinet ..........................................................................................................................9

Hydraulic cabinet .........................................................................................................................9

Connections...............................................................................................................................10

Valve block................................................................................................................................10

Technical Data..........................................................................12

Assembly and Installation ........................................................13

Electrical Connection......................................................................................................................13

Check valve ..................................................................................................................................13

Brine tank .....................................................................................................................................13

Connecting the brine filter ...........................................................................................................14

Neuthox tank ................................................................................................................................14

Dosing Pump.................................................................................................................................15

Dosing connector...........................................................................................................................15

Water meter..................................................................................................................................15

Communication .............................................................................................................................15

Ethernet Modbus ........................................................................................................................15

SMS communication ...................................................................................................................15

Neuthox production configurations ..........................................15

Softener settings.............................................................................................................................16

Brine pump start up.....................................................................................................................16