SERVICE MANUAL

8SM-ECB70/802019001-EN

ECB70/80

9

SM-ECB70/802019001-EN

7.Warning Equipment

(1)Check if working lights work properly.

(2)Check if turning lights work properly.

(3)Set the gear to “Reverse” and check if reversing lights work and reversing beeper

sound

(4)Press horn to see if it works.

(5)Check if other warning equipment work properly.

8.Braking System

(1)Fully depress and then release the braking pedal and check if there is any abnormality.

(2)Check if the parking brake works properly when it is applied. Check the operating force

needed to fully apply the parking brake. Check for abnormal wear on the parking brake.

(3)Check the braking fluid level.

9.Driving, Steering and Operating

(1)Turn the steering wheel clockwise and anti-clockwise and check if the steering is

smooth.

(2)Operate the mechanical levers and check if lifting and tilting are smooth.

(3)Depress the acceleration pedal to see if the forklift can accelerate normally.

(4)Check for abnormal sounds during forklift operation.

10.Electric System

(1)Check the electrical wiring of the forklift.

(2)Check the fuse and relay.

(3)Check the main controller.

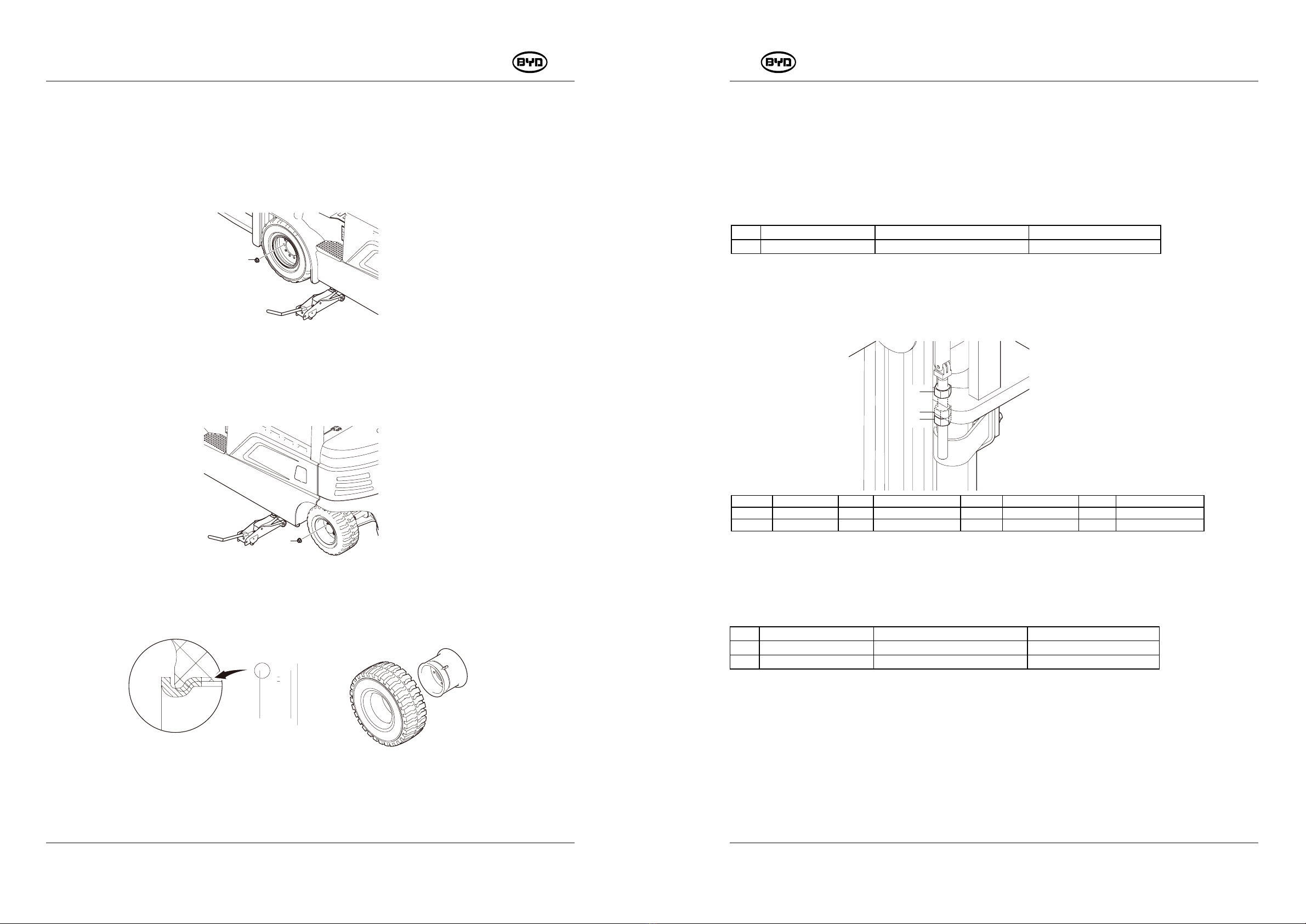

11.Counterweight

(1)Check the counterweight bolts.

(2)Check the tow pin.

12.Clean

(1)Clean the forklift.

13.Others

(1)Check if there are other problems.

Regular Maintenance

Period and Items

Period for regular inspection and maintenance, whichever comes first. For example, if the

vehicle works less than 250 hours in 6 weeks, conduct the following inspection and checks every

6 weeks, otherwise conduct the following inspection and checks every 250 hours. Perform the

maintenance service accordingly

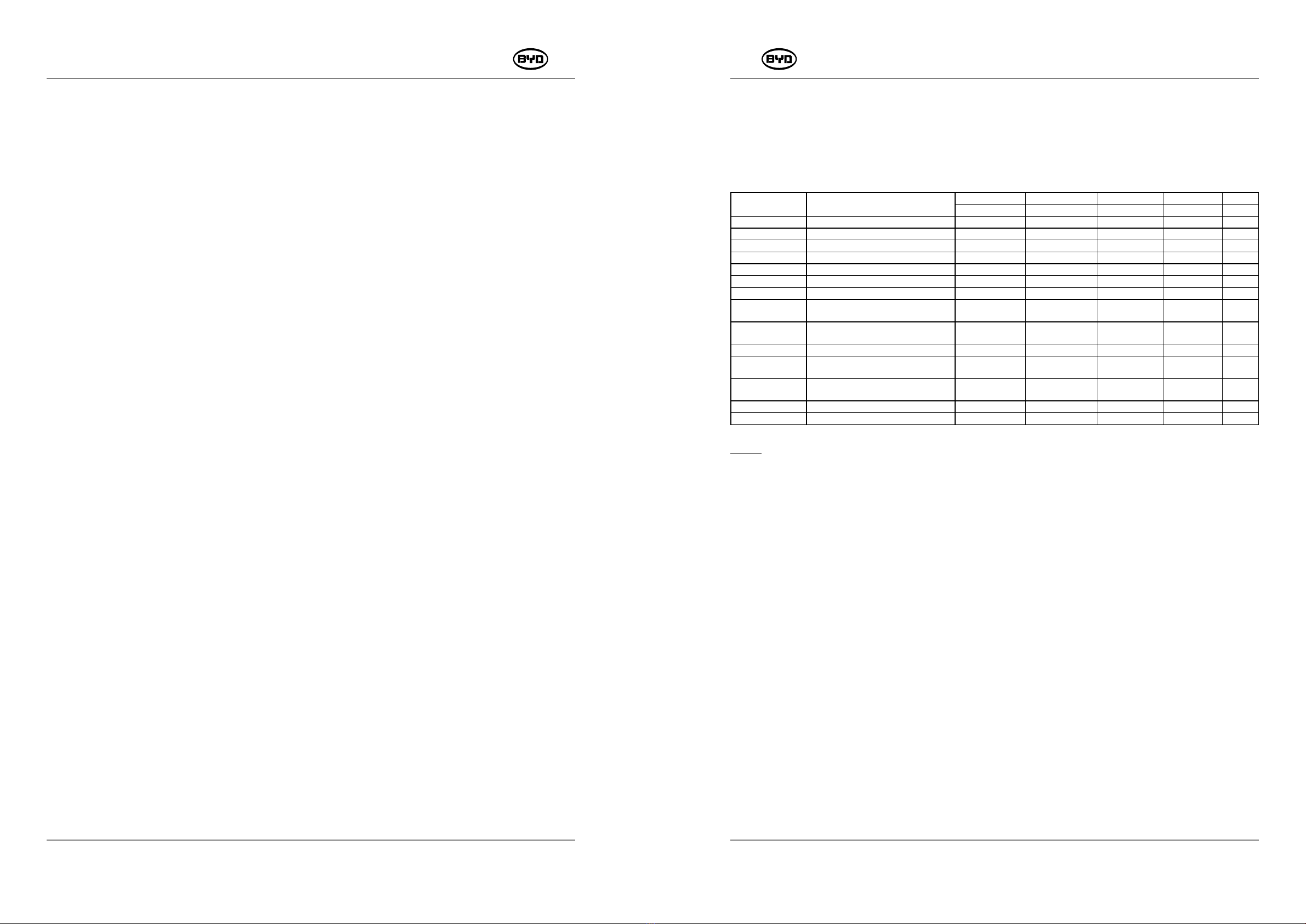

Category Items 6 weeks 3 6 12 Months

250 500 1000 2000 Hours

Chassis System Steering Axle Lubrication

Braking Fluid Replacement

Gear Oil Replacement 1st replacement Replacement

Mast Chains Adjustment Check

Lift Chains Lubrication Lubrication

Mast Cleaning Clean

Mast Lubrication Lubrication

Hydraulic System Hydraulic Oil Replacement of Main

Oil Tank

Replacement

Hydraulic Oil Replacement of Tilt

Mechanism

Replacement

Return Filter Element Replacement 1st replacement Replacement

High Pressure Filter Element

Replacement

1st replacement Replacement

Return Filter's Air Filter

Replacement

Replacement

Electric System Electric System Check

Others Torque on Critical Fasteners Check Check

Note

If the working environment is harsh, the maintenance interval should be reduced, and advice

from BYD after sales personnel should be sought.

Content Descriptions

1.Chassis System

(1)Lubricate the drive axle.

(2)Replace the brake fluid.

(3)Replace the gear oil.

2.Mast

(1)Check the tightness of the chain and adjust if necessary.

(2)Lubricate the chains.

(3)Clean the mast.

3.Hydraulic System

(1)Replace hydraulic oil regularly.

(2)Replace return filter element

(3)Replace high pressure filter element

(4)Replace air filter

4.Electric System

(1)Check the electrical wiring of the forklift.

(2)Check fuse and relay.

(3)Check the main controller.

5.Others

Check torque on critical fasteners