INTRODUCTION

ECB16S-B/ECB18S-B 18

ECB16S-B/ECB18S-B

19 OM-ECB16/18S-B2019001-EN

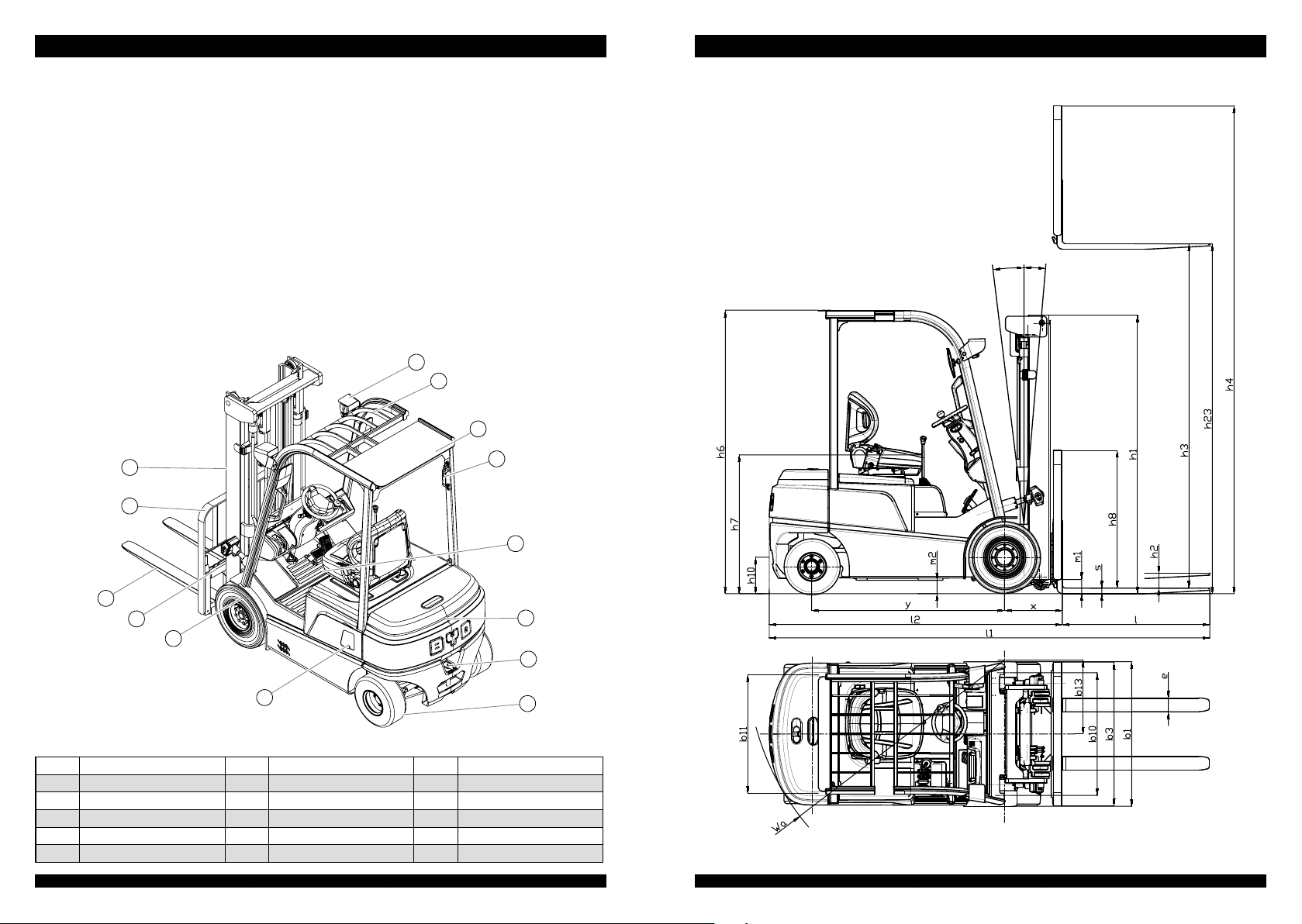

3Technical Specifications (Dual Drive)

Identification

1.1 Manufacturer BYD BYD

1.2 Model ECB16S-B ECB18S-B

1.3 Drive Electric Electric

1.4 Operator type Seat Seat

1.5 Loading capacity Q kg 1600 1800

1.6 Load center c mm 500 500

1.7 Axle centre to fork face x mm 370 370

1.8 Wheelbase y mm 1400 1400

Weight

2.1 Service weight kg 3150 3150

2.2 Axle load, with load, front/rear kg 3985/765 4312/788

2.3 Axle load, without load, front/rear kg 1390/1760 1393/1907

Wheel

3.1 Service weight kg SE SE

3.2 Axle load, with load, front/rear kg 18x7-8 18x7-8

3.3 Axle load, without load, front/rear kg 15x4.5-8 140/55-9

3.4 Wheels, number front/rear (X=driven wheels) 2x/2 2x/2

3.5 Track width, front b10 900 900

3.6 Track width, rear b11 900 900

Basic

Dimensions

4.1 Tilt of mast/fork carriage forward/backward α/βdeg 5/7 5/7

4.2 Height, mast lowered h1 mm 2020 2020

4.3 Free lift h2 mm 120 120

4.4 Lift height h3 mm 3000 3000

4.5 Height, mast extended h4 mm 4040 4040

4.6 Height of overhead guard h6 mm 2050 2050

4.7 Seat height h7 mm 990 990

4.8 Coupling height h10 mm 250 250

4.9 Overall length l1 mm 3145 3145

4.10 Length to face of forks l2 mm 2075 2075

4.11 Overall width b1 mm 1060 1060

4.12 Fork dimensions s/e/l mm 40/100/1000 40/100/1000

4.13 ISO2328, frame/type A, B 2A 2A

4.14 Fork carriage width b3 mm 1040 1040

4.15 Ground clearance, below mast m1 mm 95/100 95/100

4.16 Ground clearance, center of wheelbase m2 mm 85/90 85/90

4.17 Aisle width for pallets 1000x1200 crossways Ast mm 3400 3400

4.18 Aisle width for pallets 800x1200 lengthways Ast mm 3590 3590

4.19 Turning radius Wa mm 1820 1820

4.20 Inward turning radius b13 mm 433 433

Performance

Data

5.1 Travel speed, with/without load Km/h 16/16 16/16

5.2 Lift speed, with/without load mm/s 420/480 420/480

5.3 Lowering speed, with/without load mm/s 480/460 480/460

5.4 Max.drawbar pull, S2=5min, with/without load KN 9/8 9/8

5.5 Max.gradeability, S2=5min, with/without load % 20/20 20/20

5.6 Service brake 4.5/4 4.5/4

5.7 Service brake Mech./Hydr. Mech./Hydr.

Drive

6.1 Drive motor rating, S2=60min kW 5Kwx2 5Kwx2

6.2 Lift motor rating at S3=15%ED kW 16 16

6.3 Battery voltage, nominal capacity 80/270 80/270

6.4 Battery weight Mpa 650 650

7.1 Type of drive control AC AC

7.2 Operating pressure for hydraulic system MPb ≤16 ≤18

7.3 Sound level at the driver's ear dB(A) ≤75 ≤75

7.4 Towing coupling, type PIN PIN

1. Mast Specifications (Single Drive)

2-Stage Standard Mast 2-Stage Free Lift Mast 3-Stage Free Lift Mast

Lift height h3 3000 3500 4000 4500 3000 3500 4000 4500 4800 5000 5500 6000 6500

Fork height h23 3040 3540 4040 4540 3040 3540 4040 4540 4840 5040 5540 6040 6540

Height, mast lowered h1 2020 2270 2570 2820 2027 2277 2577 2102 2202 2252 2402 2672 2872

Load backrest height h8 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Height, mast extended

(without load backrest) h4 3610 4110 4610 5110 3670 4170 4670 5160 5460 5660 6160 6660 7160

Height, mast extended

(with load backrest) h4 4040 4540 5040 5540 4040 4540 5040 5540 5840 6040 6540 7040 7540

Free lift (without load

backrest) h2 125 125 125 125 1431 1681 1981 1506 1606 1656 1806 2076 2256

Free lift (with load

backrest) h2 125 125 125 125 835 1085 1385 1062 1162 1212 1362 1632 1812

Mast/fork carriage tilt,

forward/rearward α/β5/8 5/8 5/8 5/5 5/8 5/8 5/8 5/5 5/5 5/5 5/3 5/3 5/3

Axle centre to fork face x 420 420 420 420 420 420 420 431 431 431 431 431 431

2.Mast Specifications (Dual Drive)

2-Stage Standard Mast 2-Stage Free Lift Mast 3-Stage Free Lift Mast

Lift height h3 3000 3500 4000 4500 3000 3500 4000 4500 4800 5000 5500 6000 6500

Fork height h23 3040 3540 4040 4540 3040 3540 4040 4540 4840 5040 5540 6040 6540

Height, mast lowered h1 2020 2260 2510 2809 2027 2320 2570 2045 2153 2245 2445 2645 2845

Load backrest height h8 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Height, mast extended

(without load backrest) h4 3625 4125 4625 5125 3605 4105 4605 5130 5430 5630 6130 6630 7130

Height, mast extended

(with load backrest) h4 4040 4540 5040 5540 4040 4540 5040 5540 5840 6040 6540 7040 7540

Free lift (without load

backrest) h2 120 120 120 120 1415 1715 1965 1415 1606 1615 1815 2015 2215

Free lift (with load

backrest) h2 120 120 120 120 970 1270 1520 1995 1162 1195 1395 1595 1795

Mast/fork carriage tilt,

forward/rearward α/β5/7 5/7 5/7 5/5 5/7 5/7 5/7 5/5 5/5 5/5 5/3 5/3 5/3

Axle centre to fork face x 365 365 365 365 365 365 365 385 385 385 385 385 385

2. Battery Specifications

1.6t/1.8t

Battery voltage, nominal

capacity V/Ah 80/270

Battery weight kg 650

Working Environment

Temperature:-10 ~ 40℃

Gradeability:≤20%

Others: no flammable gas, no flammable dust and no volatile flammable liquid