EPS14

5SM-EPS142016002-EN

REGULAR MAINTENANCE

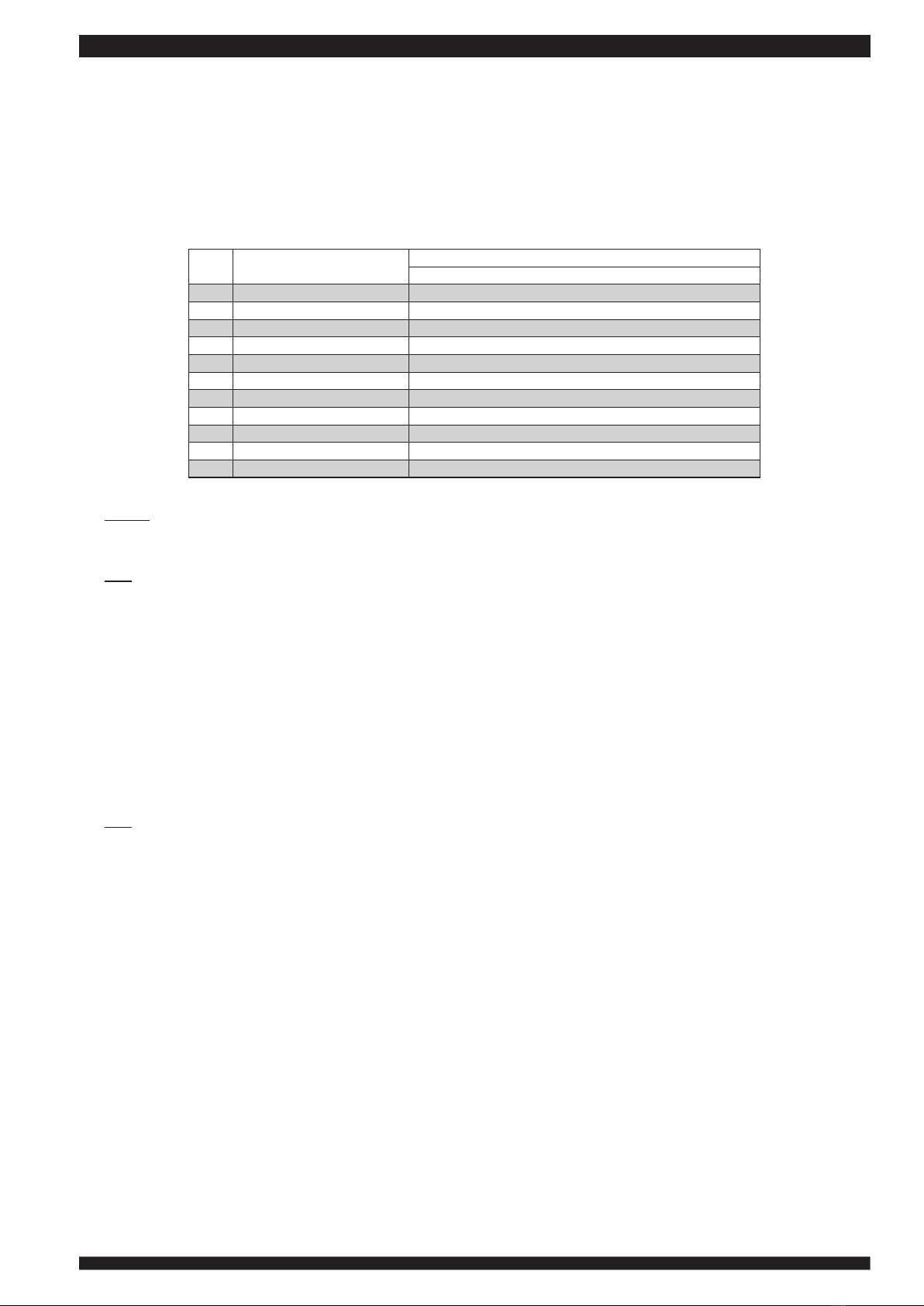

Integral and Items

The period is accumulated in months or hours of operation whichever comes first. For example, if the truck works less than 250

hours in 6 weeks, conduct the following inspection and checks every 6 weeks, otherwise conduct the following inspection and checks

every 250 hours.

Category Item

6 (Weeks) 3 6 12 Months

250 500 1000 2000 Hours

Chassis Gear Oil Level Checking First Check Inspection

Mast

Lift Chain Adjustment Adjust

Lift Chain Lubrication Lubricate

Mast Cleaning Clean

Mast Clearance Adjustment Adjust

Hydraulic

Hydraulic Oil Replacement Replace

Oil Filter with Breather Filter Replace

Electric Electric Checking Inspection

Others Critical Fasteners Torque Checking Inspection

Note

If the working environment is harsh, the maintenance interval should be reduced, and advice from aftersales personnel should be

sought.

Category, Amount And Type of Supplementary Material

Item Category Amount Type

Gear Oil Level Checking Gear Oil 1.05 L SAE 80W-90

Lift Chain Lubrication Machine Oil As Needed 20# (Winter), 40# (Other Seasons)

Hydraulic Oil Replacement Hydraulic Oil 9 L ISO VG46 ( ≤46°C), ISO VG68 ( ≤68°C)

Note

The given quantities are maximum values and take the actual quantities as the standard.

Content Description

1. Chassis

Check the gear oil level, add it if necessary.

2. Mast

(1) Check the tension the lift chains, adjust them if necessary.

(2) Lubricate the lift chains.

(3) Clean the lift chains.

3. Hydraulic

(1) Replace the hydraulic oil periodically.

(2) Replace the oil filler with breather filler periodically.

4. Electric

(1) Check the circuit of the truck.

(2) Check fuses and relays.

Check the controller.

5. Others

Check the torque on the critical fastener.