13

EN

7) INSTALLING THE AUTOMATION SYSTEM

1 Remove the vent screw VS with its RS gasket. (see fig.12 and note "Vent screw")

2 Before fixing the gear motor, the protection cover encoder circuit P (Figure 7) must be attached. The cover must be positioned on the side of the

motor facing the gate, therefore the position is different if the gear motor is to be placed on the left or right door.

3 Establish the height of the automation from the ground (preferably as close to the centre of the wing as possible and along a solid cross rail).

Remember that under the operator there is a vent hole (fig.12) and in certain conditions (e.g. rain or snow) it may draw liquid into the automation.

For this reason it is best not to install the operator too close to the ground.

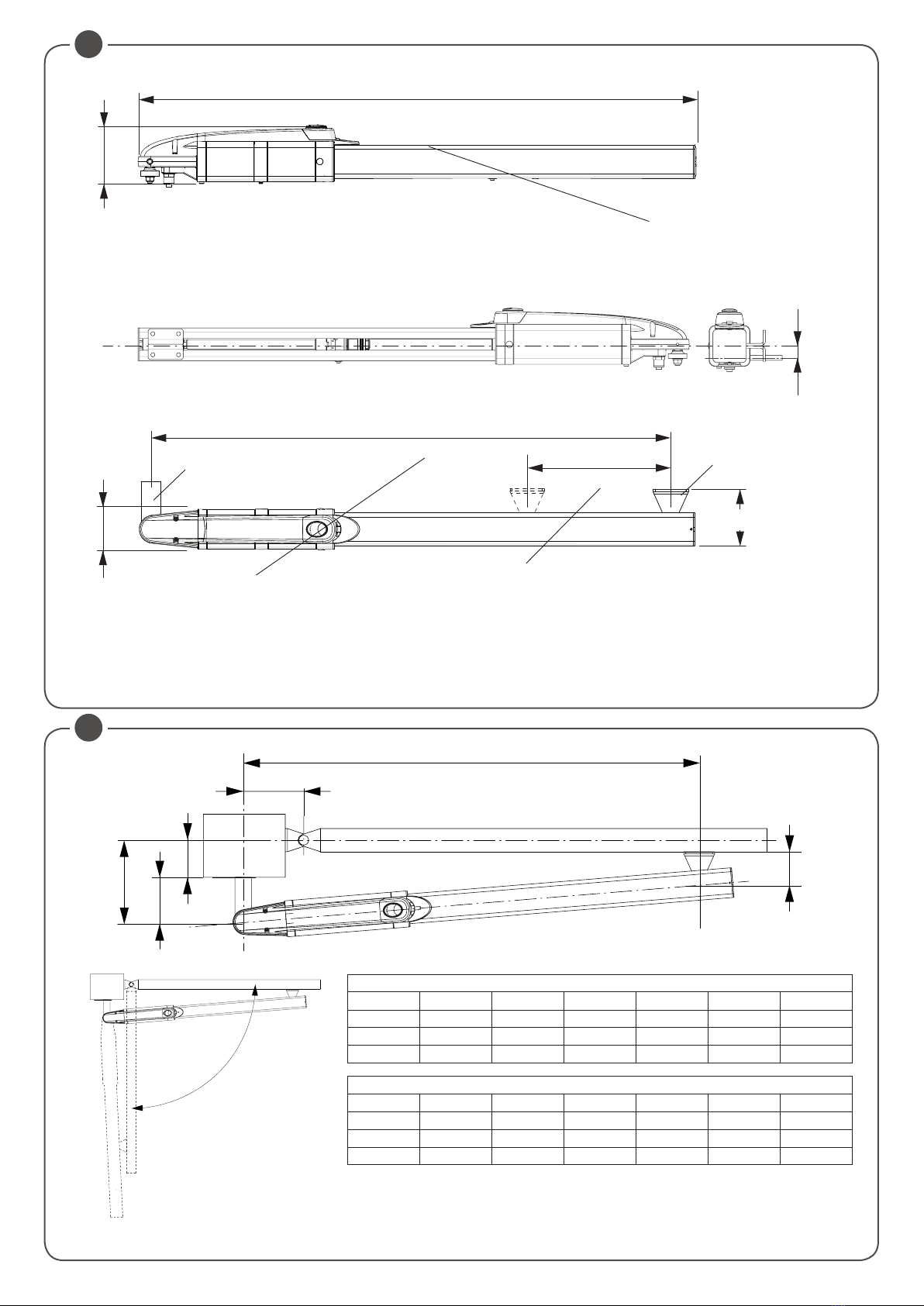

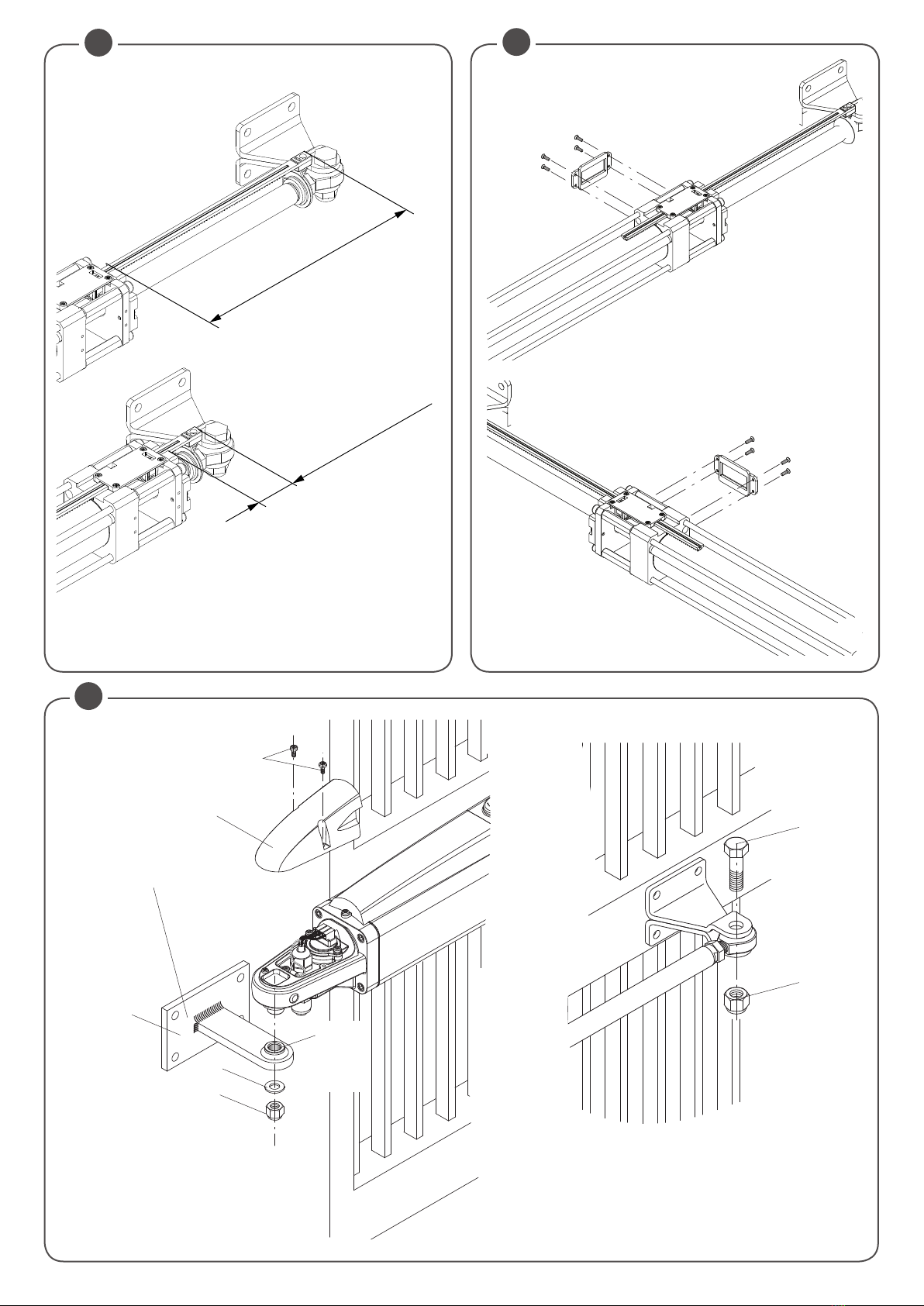

4 Weld or otherwise anchor plate P in place, see installation distances (Fig.2) and the installation diagram (Fig.8):

- remove screws V and cover C

- insert pin P in bracket P as in the figure

- lock everything in place by washer R and self-locking nut D

Observe the distances given in the tables at fig. 2, correcting the length of the plate if necessary. In some cases a recess may have to be made in the post.

It is essential that the installation distances are respected for the operator to work correctly.

With reference to the installation tables note that:

For the wing to open 90°: A+B must be equal to the operator stroke

For the wing to open more than 90°: A+B must be less than the operator stroke.

Keep the length differences within 40mm. Over this difference the wing movement becomes uneven. When reducing lengths A and B , increase the wing speed.

Comply with all statutory regulations.

5 Release the operator (see section “manual gate operation”)

Normally the gear motor is supplied already unlocked.

6 Slide out the ram shaft completely and then slide back in by approx. 10 mm. Lock the operator in place (fig.4).

Always leave a safety overrun of 10 mm in both the closing and opening strokes. The stroke length given in the technical data and installation tables

has already been reduced by the necessary 20 mm.

Before proceeding with the fixing of the actuator on the door check that the values measured on the Encoder rack, as shown in Fig. 6 are respected.

7 Make sure the operator is kept perfectly level and mark the point where the bracket will be attached to on the wing.

Temporarily weld or bolt the bracket in place as shown in Fig.8.

A horizontal position of the actuator is always preferable, but if necessary, the joints on the brackets allow for good operation even if tilted slightly,

as shown in Fig.5.

8

Release the operator and swing the gate by hand to check it moves freely to fully open and stops on the gate stop. The wing must move smoothly and evenly.

9 Anchor the bracket permanently.

NOTE: Vent plug (fig.12).

Next to the vent a dead hole has been provided where the plug and gasket can be kept for future use. On removing the plug and during the first opera-

tor manoeuvres a small quantity of oil may leak out. This is perfectly normal and should not be considered a fault.

8) MANUAL AND EMERGENCY GATE OPERATION (FIG.9-10)

If there is a power failure or malfunction the wings can be moved by hand as follows:

Models with hydraulic lock (i.e. HD.35 C -HD.35 AC - HD.50 AC):

• Use the special key supplied with the operator to open the protective cover of the release mechanisms (Fig.9).

• Turn the knob anticlockwise to disengage the automation. (Fig.10)

• The wing can now be opened and closed manually.

• To engage the automation turn the knob anticlockwise.

• Lock the cover shut.

Models without hydraulic lock (i.e. HD.35 - HD.45 - HD.50):

Since these models are reversible, simply open the electric lock and the wing can be moved manually.

Slowly push the wing by its outer end, accompanying it all the way to the gate stop. The movement may be made easier by slackening the release knob.

9) ADJUSTING THE THRUST

The actuator push force adjustment is performed electronically from the central control unit.

CAUTION! This adjustment is directly linked to the safety level of the automation.

Make sure that the thrust applied on the wing complies with statutory regulations.

10) THE PROTECTIVE COVERS (FIG.11)

Take great care in ensuring that the drain hole faces the ground.

11) WIRING (FIG.13)

The operator is supplied with the wiring cable already installed and wired (Fig.13). To connect it to the control unit see the diagram and instructions for

the control unit. The power cable is best protected by a 12mm spiral sheath that has to be inserted in the coupling provided.

12) TOPPING UP/CHANGING OIL (FIG.15)

The oil level in all hydraulic operators must be periodically checked.

For normal use, it is recommended to replace the oil every 5 years, for particularly intensive use, replacement is preferable every 2/3 years.

For refilling, after disconnecting the system power supply, simply remove the two V screws securing the terminal block, remove the three H screws

securing the C plastic cover and remove the T cap. The level should not exceed the quantity shown in Fig.15.

CAUTION!: Always shut-off the mains power before working on the gate

Only use BIO OIL.

13) WIRE DIAGRAM (FIG.14)

Legend:

1 Hydro 24V geared motor

2 Photocells

3 Key selector or digital keyboard

4 Beacon

5 Antenna

6 Control unit.

7 Electric lock

N.B.: The power cables must be kept separated from the auxiliary cables.

IMPORTANT: Installation of an electric lock is essential on models without hydraulic lock or if the wing is over 2 m long