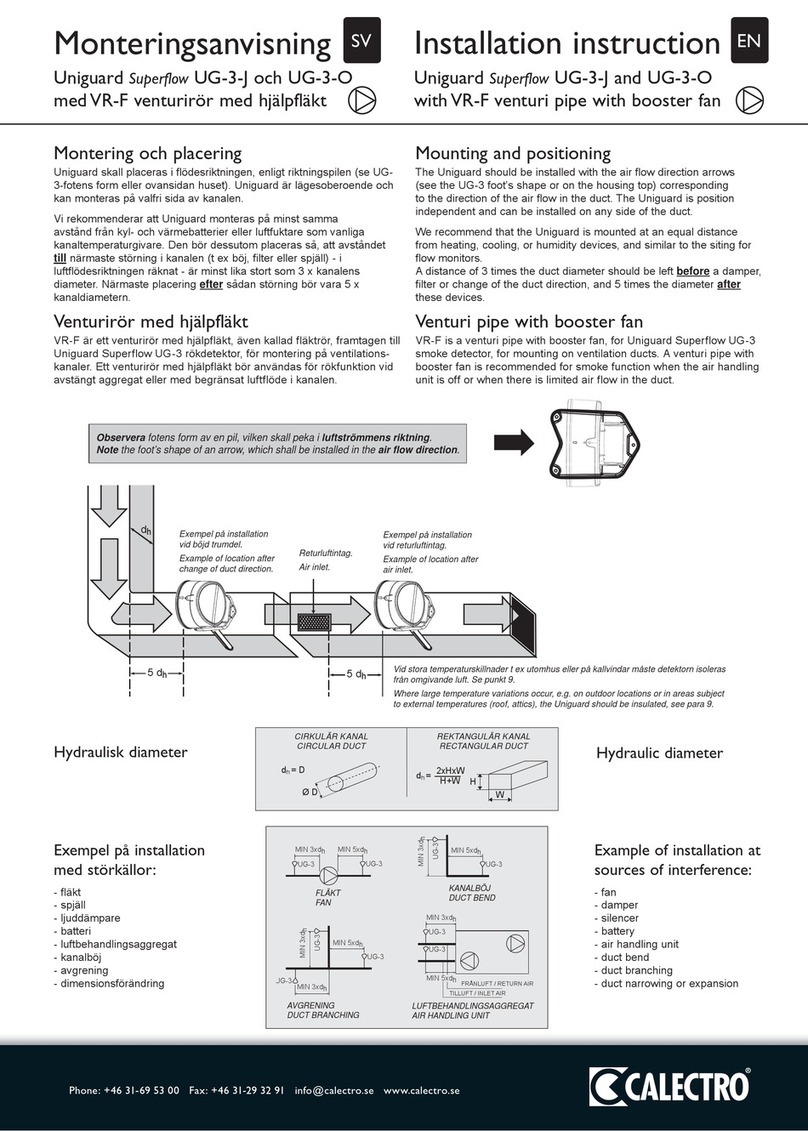

CALECTRO Uniguard 8 User manual

Other CALECTRO Smoke Alarm manuals

CALECTRO

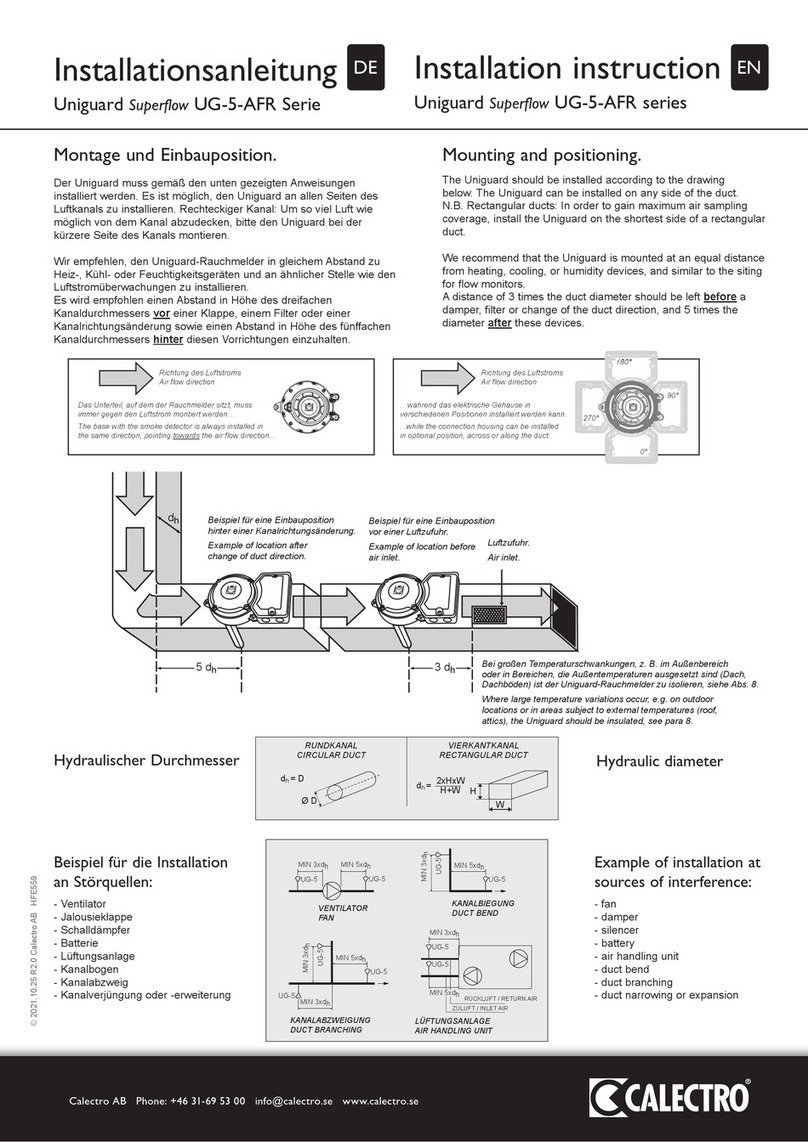

CALECTRO UG-5-AFR-230V User manual

CALECTRO

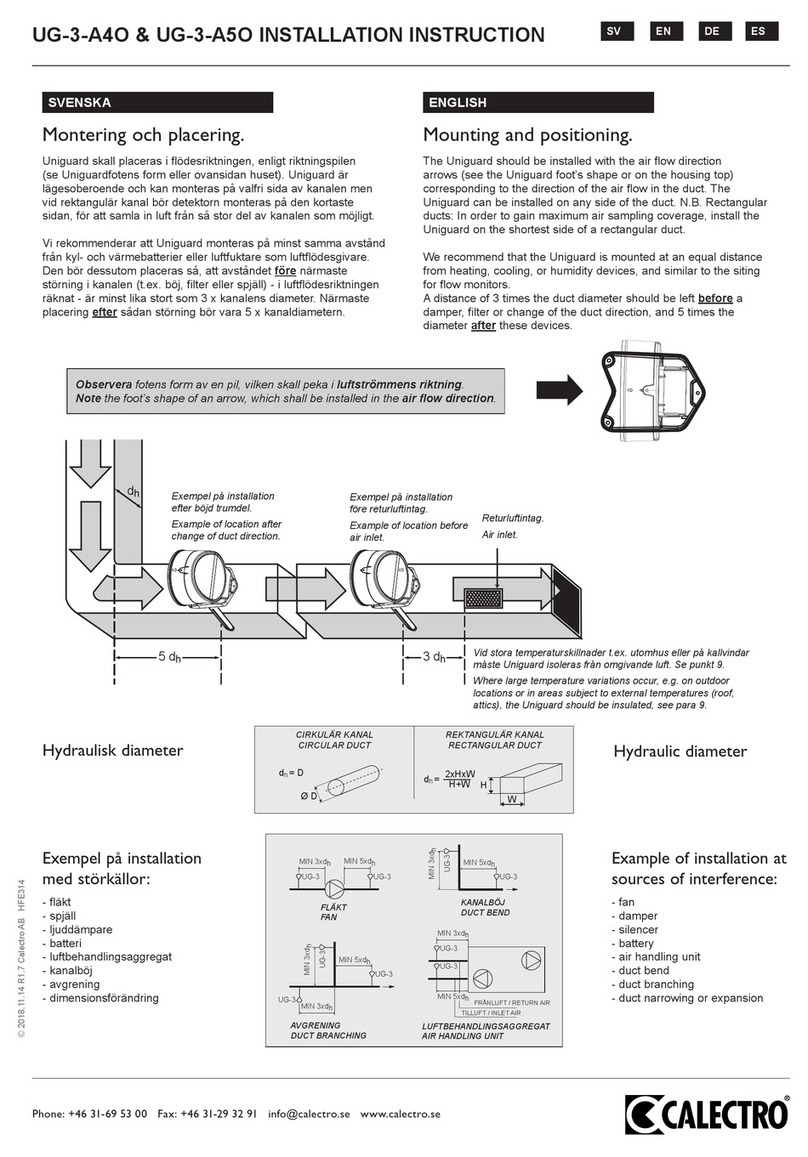

CALECTRO UG-3-A4O UNIGUARD SUPERFLOW User manual

CALECTRO

CALECTRO Superflow UG-5-AFR-230V-MB User manual

CALECTRO

CALECTRO UG-3-A4O User manual

CALECTRO

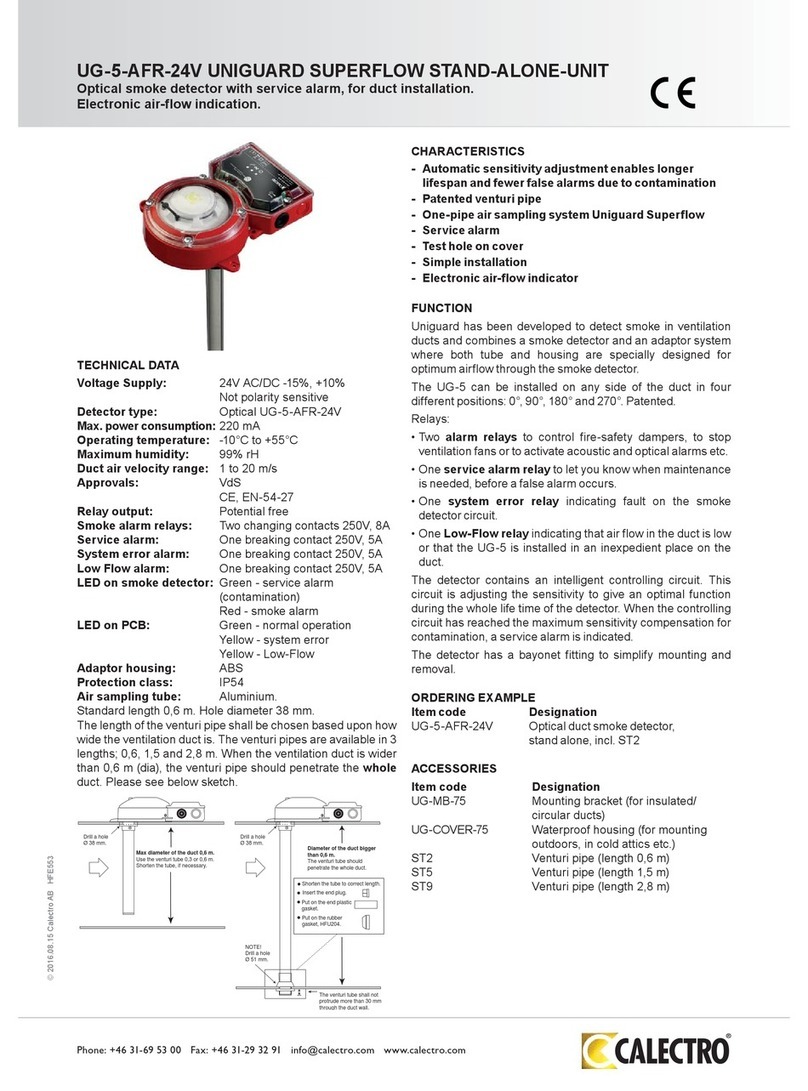

CALECTRO UG-5-AFR-24V UNIGUARD SUPERFLOW User manual

CALECTRO

CALECTRO Uniguard Superflow UG-5-AFR Series User manual

CALECTRO

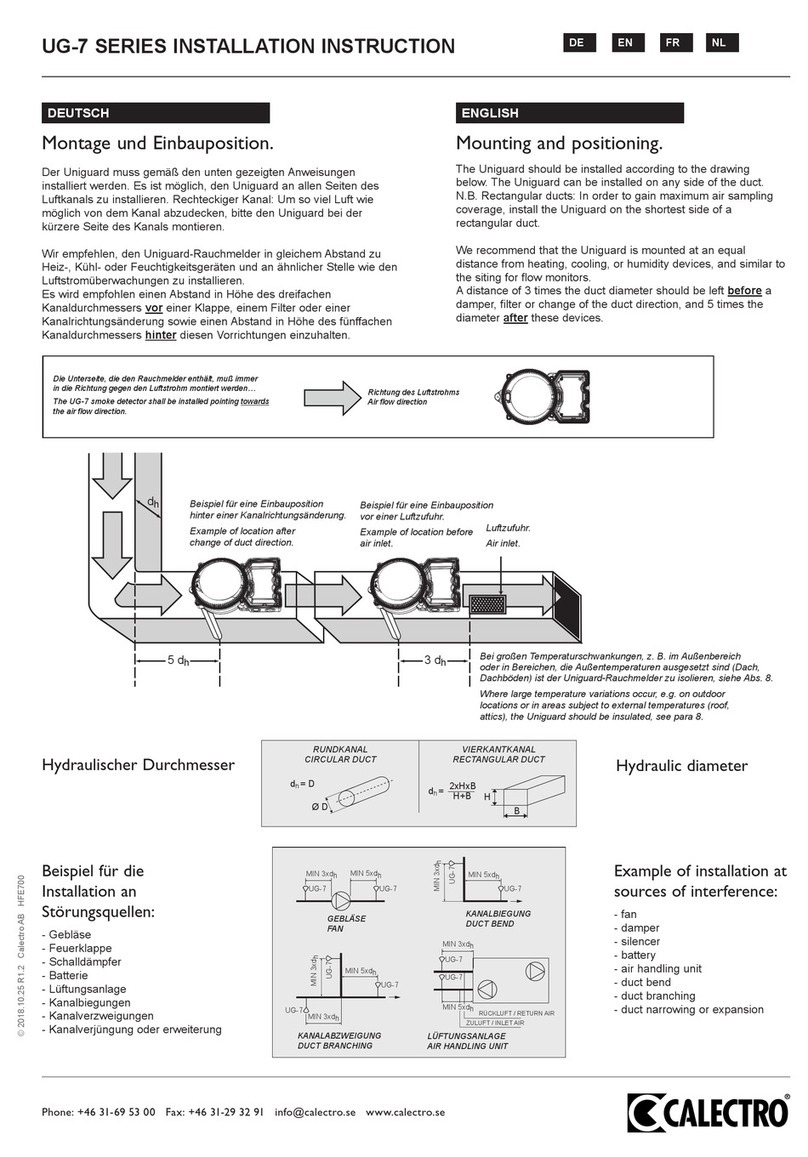

CALECTRO UG-7 Series User manual

CALECTRO

CALECTRO Uniguard Superflow UG-3-O User manual

CALECTRO

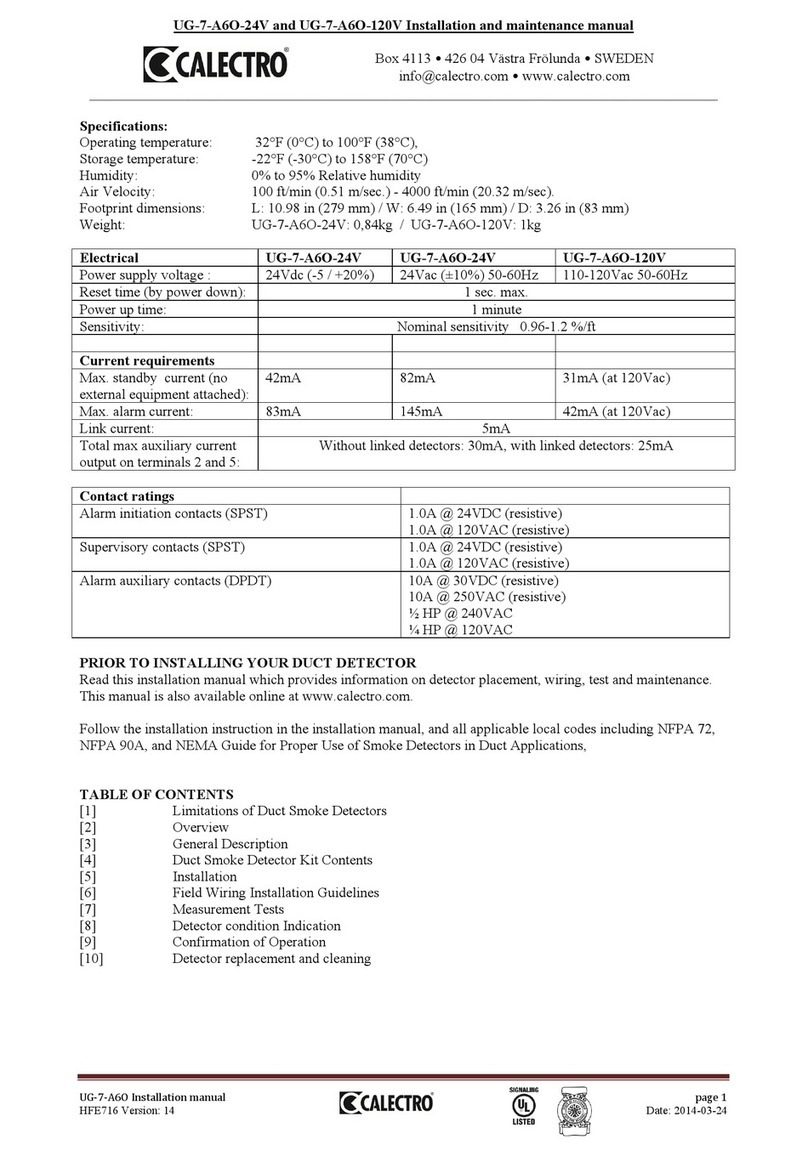

CALECTRO UG-7-A6O-120V Manual

CALECTRO

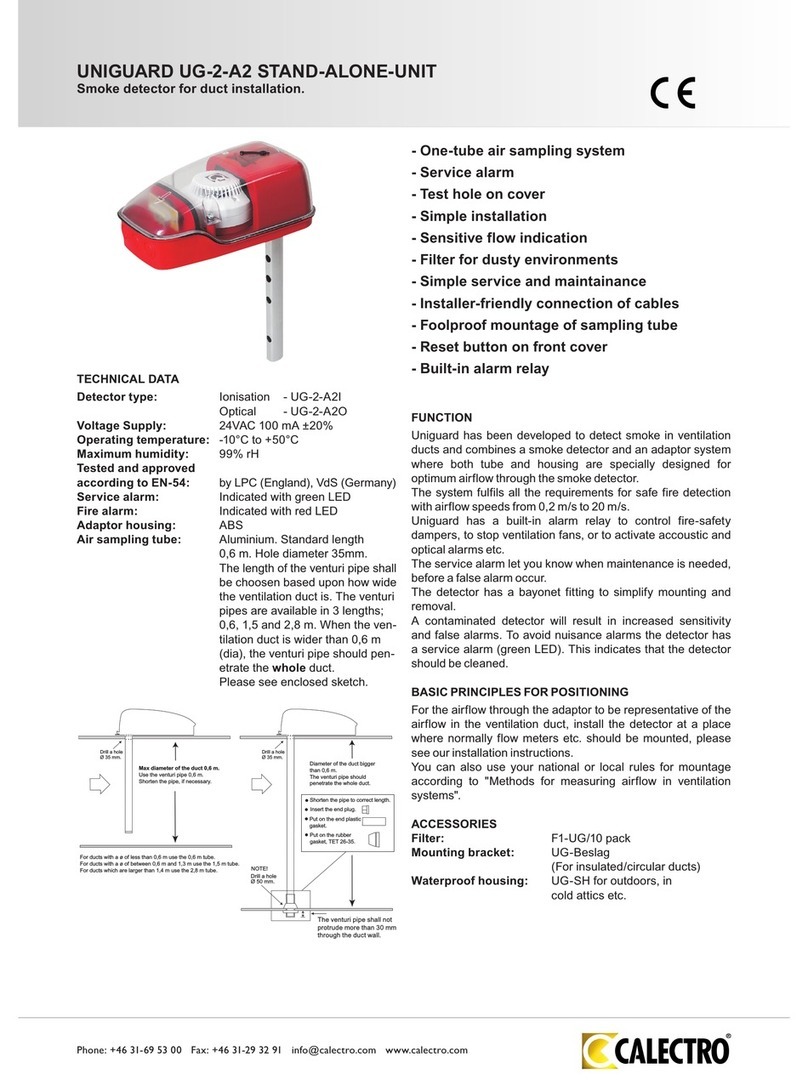

CALECTRO UNIGUARD UG-2-A2 User manual

Popular Smoke Alarm manuals by other brands

x-sense

x-sense SD19-W user manual

FireAngel

FireAngel Thermoptek ST-622 user manual

teko

teko Astra-42A user guide

Siemens

Siemens PE-11C installation instructions

System Sensor

System Sensor DH500ACDC Installation and maintenance instructions

Resolution Products

Resolution Products RE612 CryptiX quick start guide