THE COMPLETE CALMER RESIDUE MANAGEMENT DELUXE

UPGRADE KIT INCLUDES PER ROW:

Note: Your reference for Right and Left (Stalk Rolls) is as you are sitting in the combine cab looking

at the corn head.

THIS SYMBOL MEANS: ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in

death or serious injury. This signal word is to be limited to the most extreme situations

typically for machine components which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result

in death or serious injury, and includes hazards that are exposed when guards are removed.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

NOTICE is used to address safety practices not related to personal safety.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator

should be a responsible adult familiar with farm machinery and trained in this equipment’s

operations. Do not allow persons to operate or assemble this unit until they have

read this manual and have developed a thorough understanding of the safety

precautions of how it works.

SAFETY SIGNS

Sharp Objects signs are placed on the exterior of all stalk roll boxes. See

the sign, right, for reference and understand the associated cutting dangers

with the enclosed product.

BEFORE OPERATION

• Carefully study and understand this manual.

• Do not wear loose-fitting clothing which may catch on moving parts.

• Always wear protective clothing and substantial shoes.

• Always wear provided cut-resistant gloves when installing stalk rolls

3 www.CalmerCornHeads.com (309) 629-9000 4

Case IH 4000/NH 980CR Upgrade Kit

C

D

BE

A

B

C

D

E

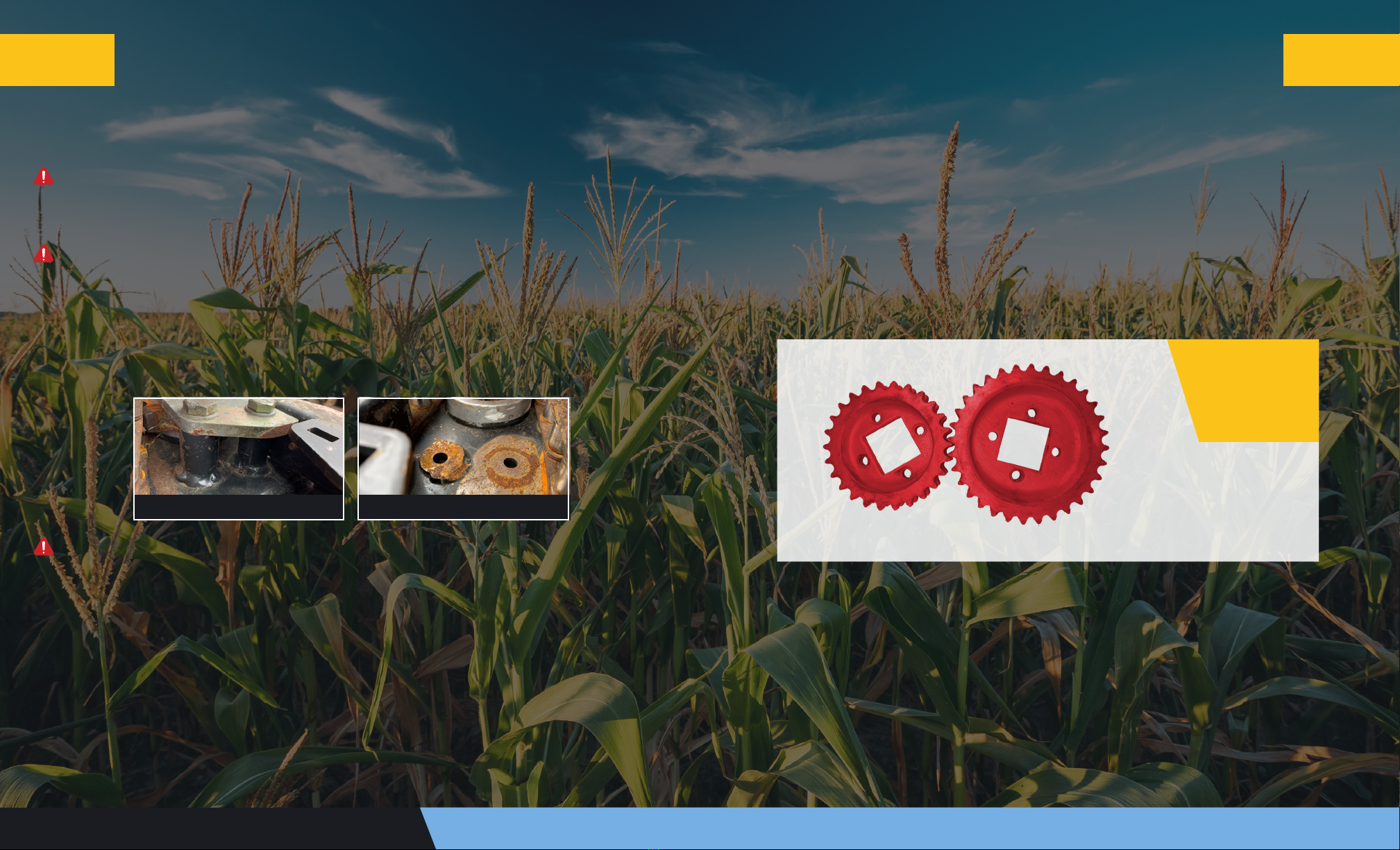

(2) BT Chopper®Stalk Roll Shells

(1) Left Manual Stripper Plate

(1) Right Hydraulic Stripper Plate

(2) Spiral Grass Knives

(2) 13-Tooth Accelerator Drive Sprockets

F

G

H

I

(2) 13-Tooth Idler Sprockets

(1) Medium-Strength Threadlocker Tube

(20) 3/8” - 16 x 1¾” Socket Head Cap

Screws

(1) Cut-O Wheel

Cut-O Wheel

G

H

(2) CUT-RESISTANT

GLOVES

The Complete Calmer Residue Management Deluxe Upgrade Kit Includes Per Head:

OIL BATH SPROCKETS

(1 pair for 6 row heads,

2 pairs for 8+ row heads)

(1) Angle Grinder

(1) Pair of Goggles

(2) Hex Bits

(1) Template for Modifying Row Units

(2) Pairs of 26:32 or 19:24 Oil Bath Sprockets

(1 pair for 6 row heads)

(2) Oil Bath Gaskets

(1 for 6 row heads)

I

AF