2- Manual FA01797-EN - 05/2022 - © CAME S.p.A. - The contents of this manual may be changed at any time and without notice. - Translation of the original instructions

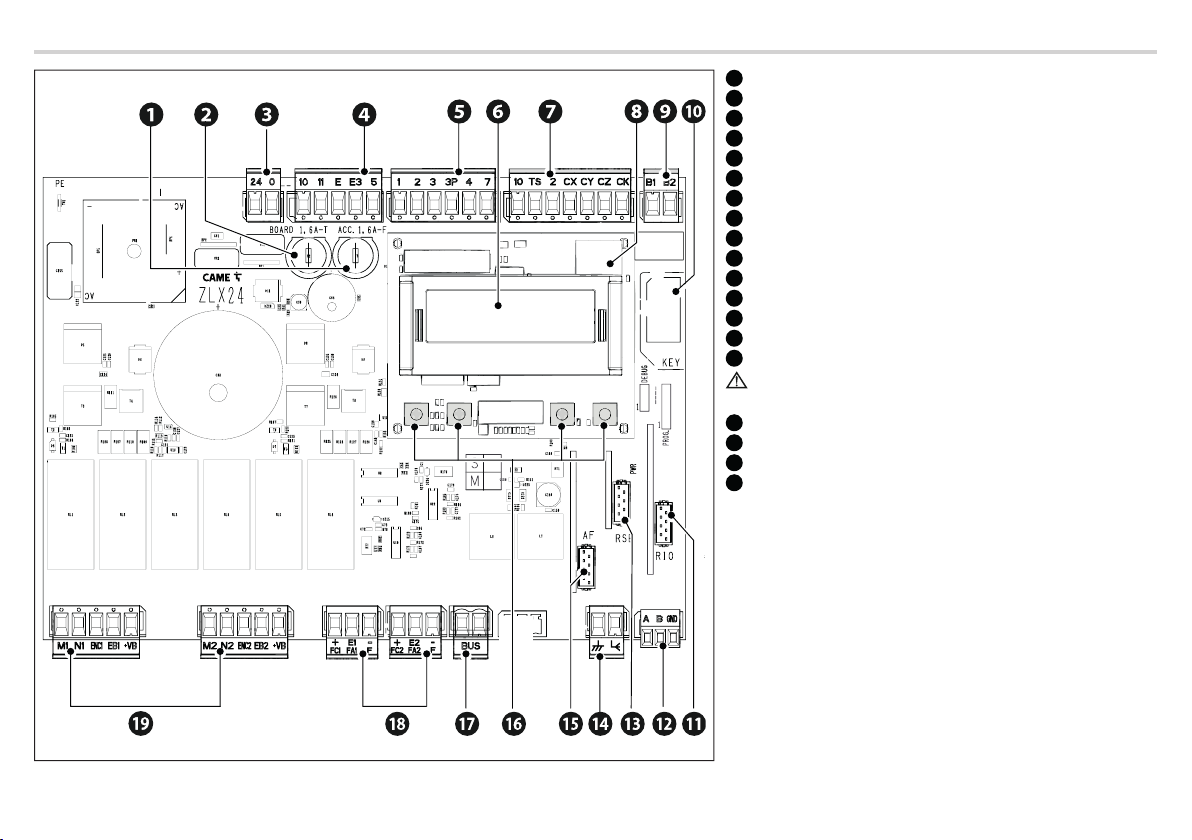

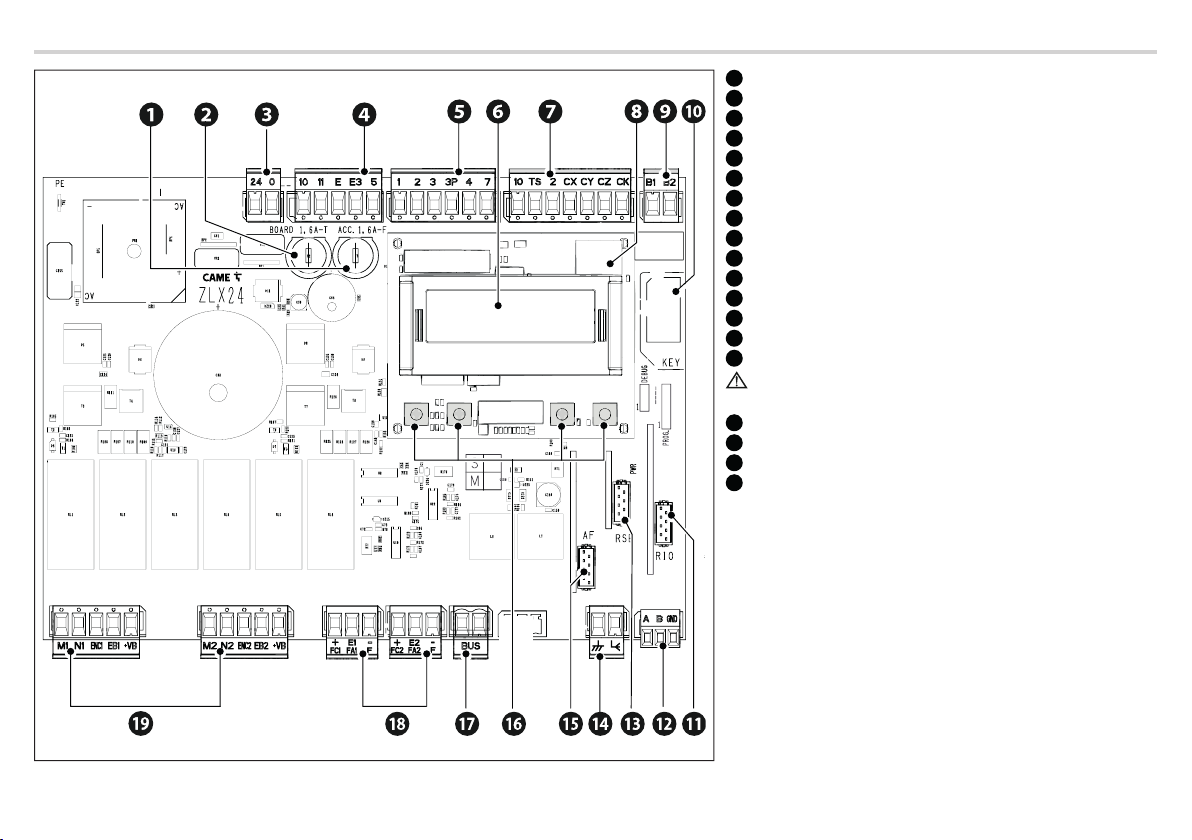

Description of control board components

1Accessories fuse

2Control board fuse

3Terminal board for power supply to the control board

4Terminal board for connecting the signalling devices

5Terminal board for connecting control devices

6Display

7Terminal board for connecting the safety devices

8Memory Roll card connector

9Terminal board for B1-B2 output

10 Connector for CAME KEY*

11 RIO CONN card connector*

12 Terminal board for CRP connection**

13 RSE card connector**

14 Terminal board for connecting the antenna

15 Connector for plug-in radio frequency card (AF)

Use only AF43S or AF868 with diagram number DIS29101 or

above.

16 Programming buttons

17 Terminal board for BUS devices*

18 Terminal boards for connecting micro limit switches and/or encoders

19 Terminal board for connecting the gearmotor with encoder or with

slowdown switch and electric lock

(*) Cannot be used

(**) Not suitable for spare part ZL19N