1

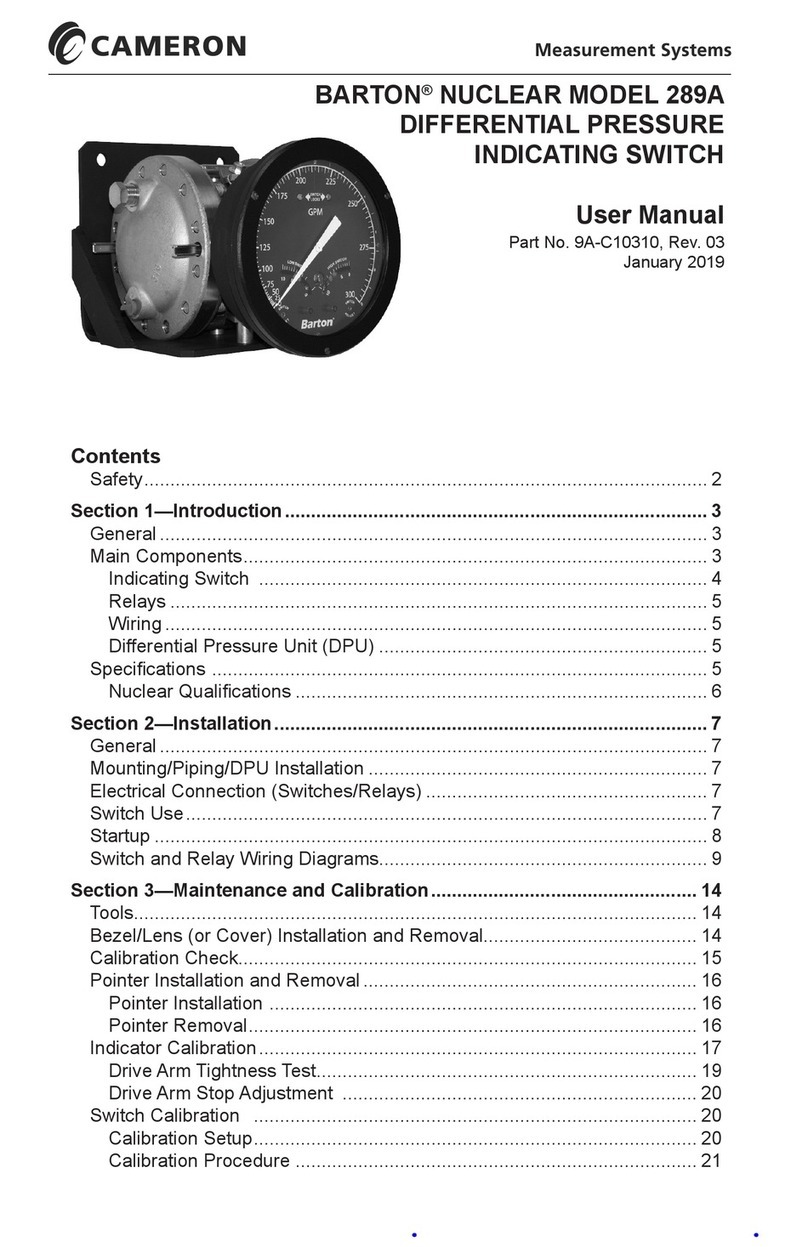

3-3. Piping — Standard Practices (Cont.)

7. Rotate the housing as necessary to place the connection in the proper

position. The DPU has connections in the pressure housings to accom-

modate various pipe sizes (refer to Section 6- Drawings).

8. Install a valve manifold connecting the DPU and the source of differen-

tial pressure to facilitate operation and checking of the DPU.

9. Locate all shutoff valves and bypass valves to be readily accessible from

the front of the instrument. Locate block valves at the source of dif-

ferential pressure.

B. Flow Applications

Assure that the DPU high-pressure housing is connected to the upstream

tap of the primary device.

NOTE: To prevent overheating the DPU during blowdown, the operator

should monitor the temperature by placing his hands on the pipe between

the DPU and the manifold pipe containing the vent valves.

C. Liquid Level Applications

The process media may be used as a reference leg seal uid when it is of a

type that will condense in the reference leg under all conditions.

If the process or process media characteristics are such that the above con-

ditions cannot be met, a special reference leg seal uid will be required. The

special seal uid media characteristics are such that the above conditions

cannot be met, a special reference leg seal uid will be required. The special

seal uid must not be volatile and must not be miscible with the process

media. Also, the difference in the densities of the special seal uid and the

process media will require compensation in calculating the differential pres-

sure range of the DPU.

WARNING

EXPLOSION HAZARD. ORGANIC COMPOUNDS, OIL, GREASE,

DIRT, OR SCALE OF ANY KIND CANNOT BE TOLERATED IN AN

OXYGEN INSTALLATION.

3-4. General Startup Practice Considerations

Observe the following practices when starting up an instrument.

1. Always start with the block valves closed.

2. Perform a zero check on the instrument as follows.

NOTICE: For gas service, it is recommended that zero check be performed

with both block valves closed. If the gas ow is pulsating, there may be a

standing wave effect in the process line which can displace the indicator

and appear as a zero error.

a. Open the bypass valve(s), then open one shutoff valve. This proce-

dure equalizes the pressure between both sides of the instrument. The

instrument should indicate zero.

b. If the instrument does not indicate zero, check for gas or liquid entrap-

ment in the lines or in the DPU (depending on the orientation of the

piping layout and service).

10