COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

viii

CONTENTS

6.2.4 Detecting a Fault in the Fixing

Assembly ........................... 4-28

7 Power Supply System ....................... 4-30

7.1 Low Voltage Circuit ................. 4-30

7.1.1 Low Voltage Power Supply Cir-

cuit ..................................... 4-30

7.1.2 Protective Functions .......... 4-32

7.2 High-Voltage Power Supply Circuit

4-32

7.3 Controlling the Energy Save Mecha-

nism .......................................... 4-32

7.3.1 Outline ............................... 4-32

7.3.2 Operation ........................... 4-32

8 Others ................................................ 4-33

8.1 Fan ........................................... 4-33

8.1.1 Outline ............................... 4-33

8.2 Back-Up Batteries .................... 4-34

8.2.1 Back-Up Function ............. 4-34

8.2.1.1 Outline .......................... 4-34

8.2.1.2 Lithium Battery (BAT1) 4-34

8.2.1.3 Vanadium Lithium Second-

ary Battery (BAT2) ....... 4-36

8.2.2 Back-Up Data .................... 4-37

8.2.2.1 Types of Data ................ 4-37

8.2.2.2 Printing the Backup Data

List ................................ 4-38

9 ADF (if equipped with ADF

functions) .......................................... 4-40

9.1 Outline ..................................... 4-40

9.2 Picking Up and Moving

Originals ................................... 4-41

9.2.1 Outline ............................... 4-41

9.2.2 Moving Down the Original

Pickup Roller and Moving Up

the Original Stopper .......... 4-42

9.3 Detecting an Original Jam ....... 4-43

9.3.1 Outline ............................... 4-43

9.3.2 Types of Jams .................... 4-43

1 Points to Note When Disassembling/As-

sembling the Machine ......................... 5-1

2 Disassembly ........................................ 5-3

2.1 Externals/Auxiliary System ....... 5-3

2.1.1 External Covers ................... 5-3

2.1.1.1 Removing the Left Cover/Rear

Cover ................................... 5-4

2.1.1.2 Removing the Right

Cover .............................. 5-4

2.1.1.3 Removing the Front

Cover .............................. 5-5

2.1.1.4 Removing the Delivery

Cover .............................. 5-5

2.1.1.5 Removing the Delivery Up-

per Cover/Delivery Rear

Cover .............................. 5-6

2.1.1.6 Removing the

Cartridge ......................... 5-6

2.1.1.7 Removing the Upper

Cover .............................. 5-7

2.1.1.8 Removing the Right

Door ................................ 5-8

2.1.2 Removing the Control

Panel .................................... 5-8

2.1.3 Removing the Copyboard

Glass .................................... 5-9

2.1.4 Removing the Main Motor

Unit .................................... 5-10

2.1.5 Remove the Heat Discharge

Fan ..................................... 5-13

2.1.6 Removing the Reader Slide De-

tecting Switch .................... 5-15

2.2 PCBs ........................................ 5-16

2.2.1 Removing the Image Processor

PCB .................................... 5-16

2.2.2 Removing the Analog Processor

PCB .................................... 5-16

2.2.3 Removing the Sensor

PCB .................................... 5-19

2.2.4 Removing the DC Controller

PCB/Power Supply PCB ... 5-20

2.2.5 Removing the Printer Controller

PCB .................................... 5-24

2.2.6 Removing the NCU PCB... 5-24

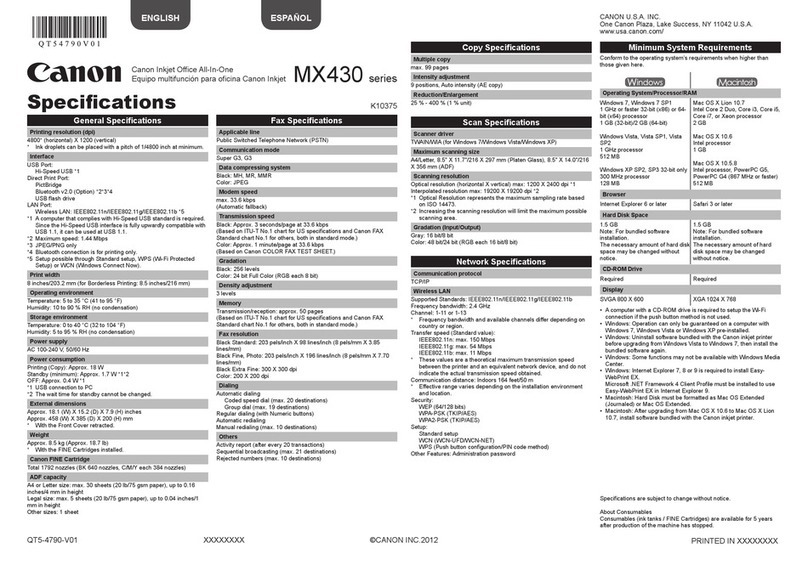

CHAPTER 5 MECHANICAL SYSTEM

Contents.p65 8/26/01, 5:04 PM8