1-3. Special Tools

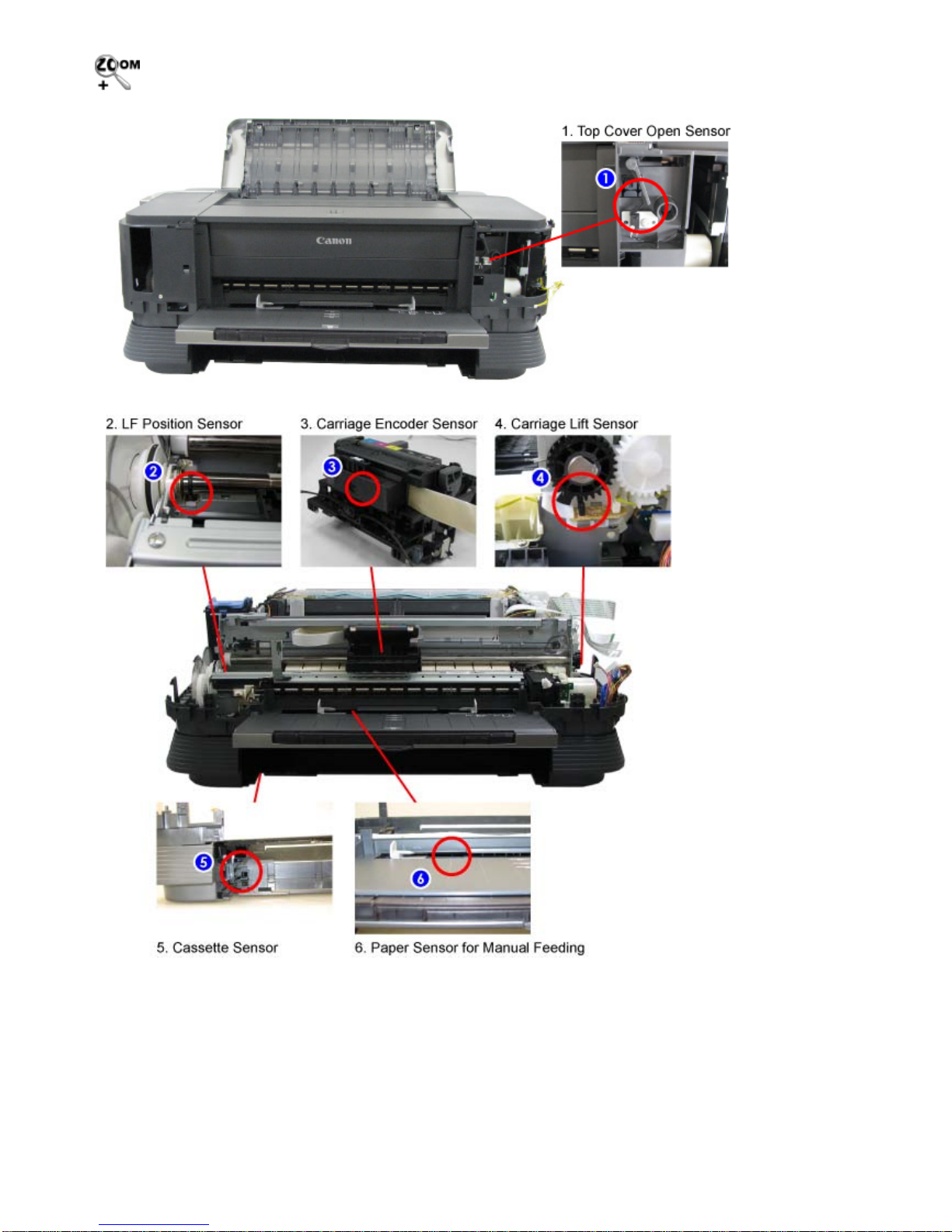

1-4. Sensors

Name Tool No. Application Remarks

FLOIL KG-107A QY9-0057-000 To the printer's sliding portions. In common with other models

on the market.

No. Sensor Function Possible problems

1Top cover open

sensor Detects opening and closing of the

top cover. - The carriage does not move to the center.

2LF position sensor Detects the standard rotation

position of the feed roller. - LF position error

3Carriage encoder

sensor Detects the position of the timing

slit film, and controls printing. - Printing shifts from the correct position.

- Carriage position error

4Carriage lift

sensor Detects the position of the carriage

lift cam. - Carriage lift mechanism error

5 Cassette sensor Detects the cassette. - No cassette

6Paper sensor for

manual feeding Detects paper in the front tray and

manual feed slot - No paper in the front tray

- Paper in the manual feed slot

- Paper not properly set in the manual feed

slot

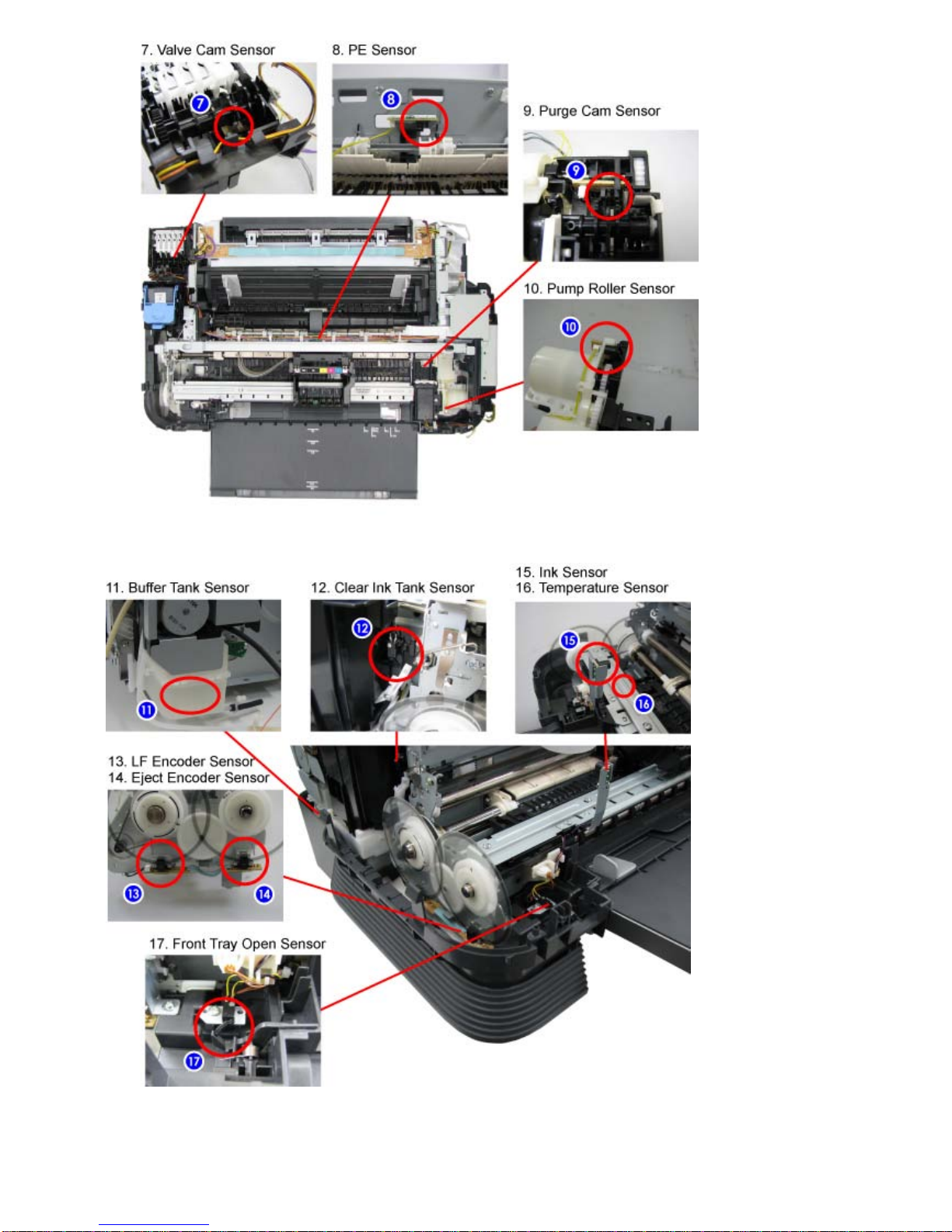

7Valve cam sensor Controls valve unit operation. - Reactor error

8PE sensor Detects paper feeding and ejection. - No paper

- Paper jam

9 Purge cam sensor Controls purging operation. - PG cam sensor error

10 Pump roller

sensor Detects the position of the pump

roller - Pump roller sensor error

11 Buffer tank sensor Detects Clear ink in the buffer

tank - No Clear ink

- Reactor error

12 Clear ink tank

sensor Detects the Clear ink tank. - No Clear ink tank

13 LF encoder sensor Detects rotation of the LF encoder,

and controls its drive. - Uneven printing

- LF position error

14 Eject encoder

sensor Detects rotation of the eject

encoder, and controls its drive. - Uneven printing at the trailing edge of paper

- Eject encoder error

15 Ink sensor Detects the position of an ink tank. - No recognition of an ink tank

- Wrong position of an ink tank

16 Temperature

sensor Detects the temperature of the

inside of the printer. - Internal temperature error

17 Front tray open

sensor Detects opening and closing of the

front tray. - Front tray closed