cassette. There is no paper.

Load paper and press

[OK].

selected as the paper source. Set

the paper in the cassette, and press

the OK button.

Note that the cassette is for plain

paper only.

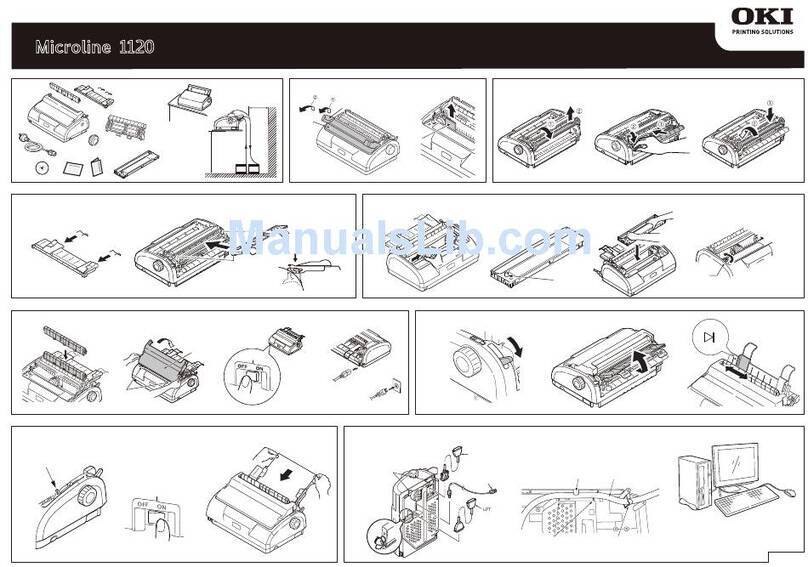

arm unit

- Pressure

roller

unit

- Cassette

unit

Paper jam. [1300] --- The paper is jammed.

Clear the paper and

press [OK].

Remove the jammed paper and

press the OK button.

For paper jam in the rear guide,

confirm that the rear guide is not

dislocated.

- Pick-up

arm unit

- ASF unit

- Pressure

roller

unit

- Cassette

unit

- Rear

guide

unit

Paper jam in the

rear guide. [1303] ---

Paper jam in the

under guide. [1304] ---

Ink may have run

out. [1600] U041 The ink may have run

out. Replacing the ink

tank is recommended.

Replace the applicable ink tank,

or press the OK button to clear the

error without ink tank

replacement. When the error is

cleared by pressing the OK

button, ink may run out during

printing.

- Spur unit

Ink tank not

installed. [1660] U043 The following ink

tank cannot be

recognized.

(Applicable ink tank

icon)

Install the applicable ink tank(s)

properly, and confirm that the

LED's of all the ink tanks light

red.

- Ink tank

- Carriage

unit

Print head not

installed, or not

properly

installed.

[1401] U051 Print head is not

installed. Install the

print head.

Install the print head properly.

If the error is not cleared, confirm

that the print head contact pins of

the carriage are not bent.

- Print

head

- Carriage

unit

Faulty print head

ID. U052 The type of print head

is incorrect. Install

the correct print head.

Re-set the print head. If the error

is not cleared, the print head may

be defective. Replace the print

head. If the error still persists,

confirm that the print head contact

pins of the carriage are not bent.

- Print

head

- Carriage

unit

Print head

temperature

sensor error.

[1403]

Faulty EEPROM

data of the print

head.

[1405]

Inner cover error [1841],

[1846] --- Inner cover is open.

close the inner cover

and press [OK].

Close the inner cover, and press

the OK button.

If the error is not cleared, examine

that the inner cover sensor is

properly installed.

- Spur unit

- Inner

cover

unit