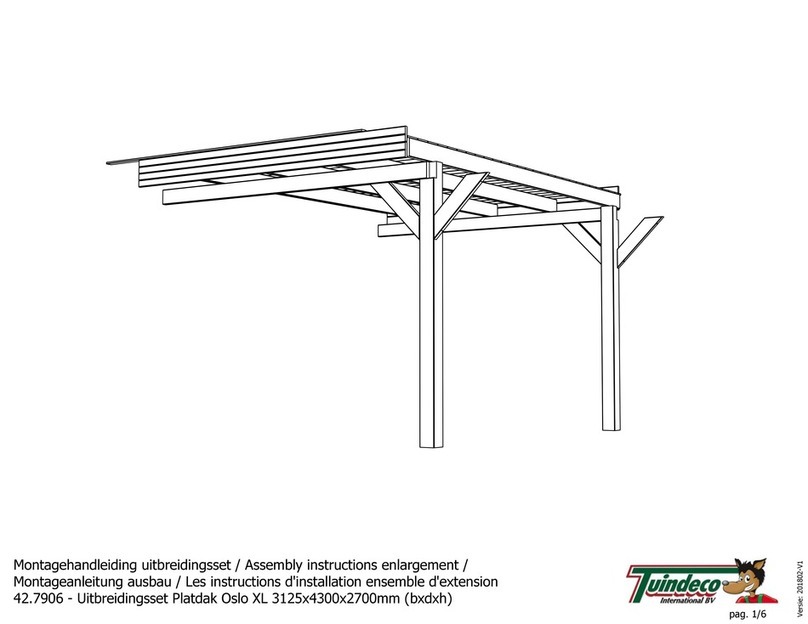

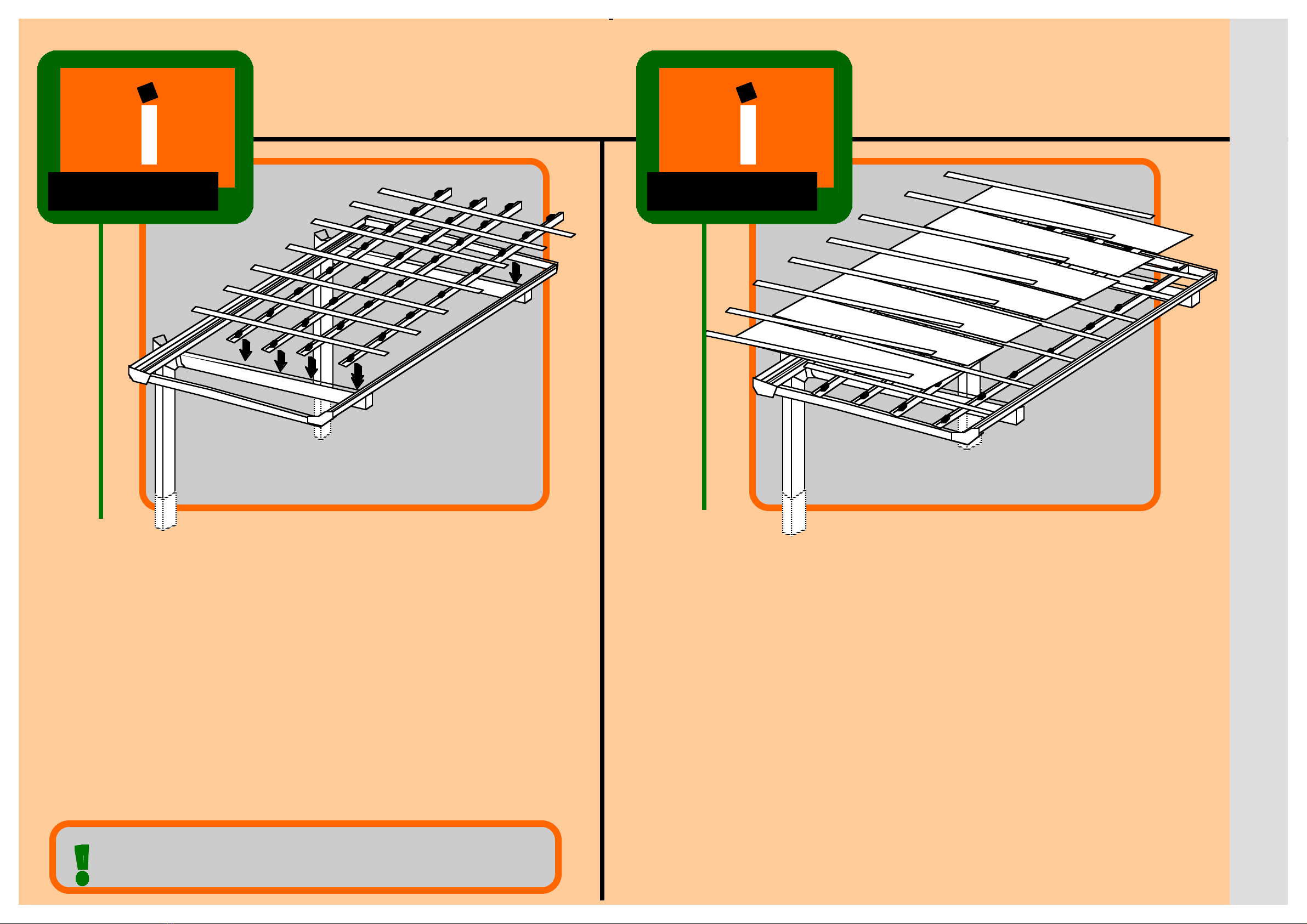

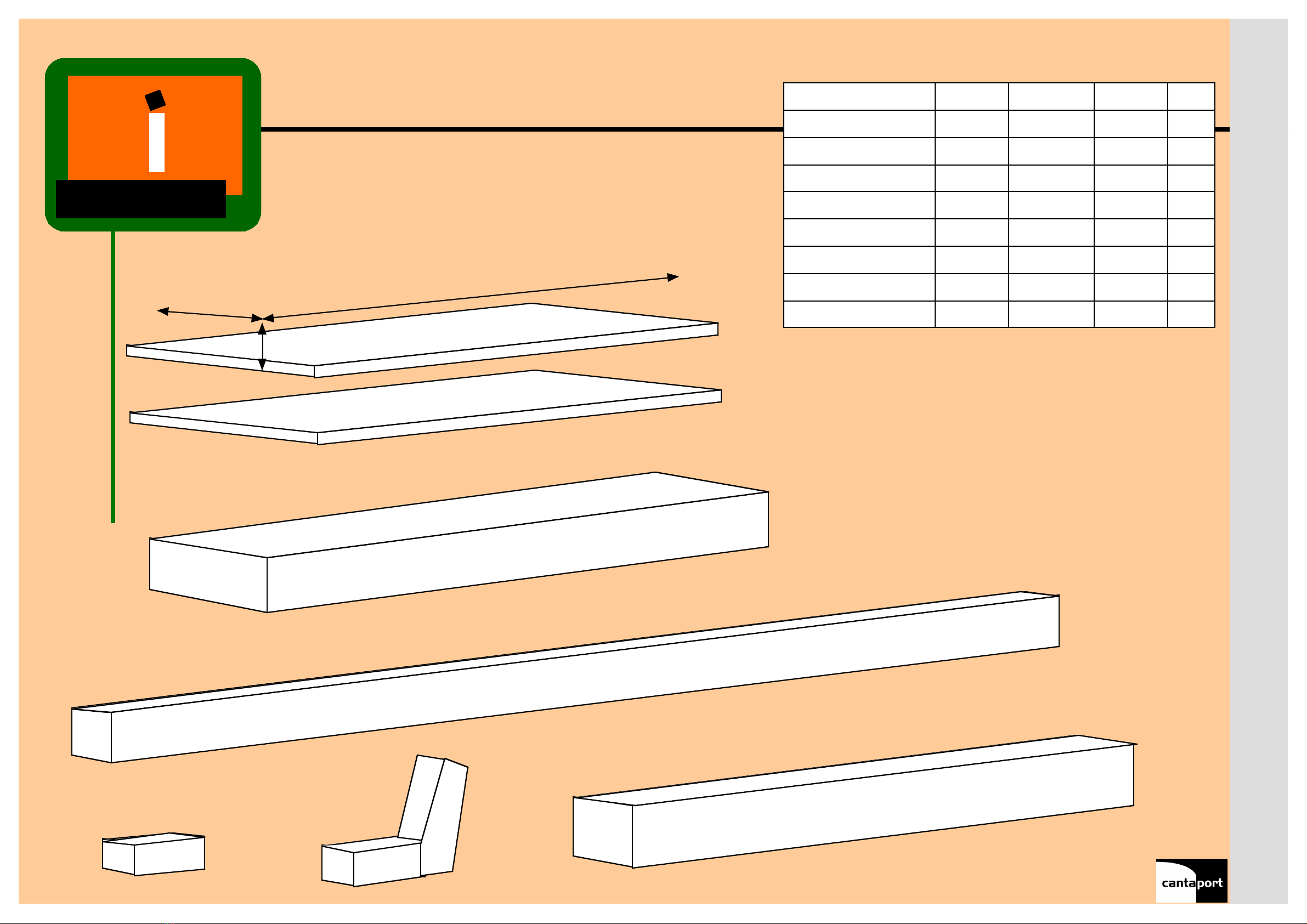

The next stage is to assemble the bearers and the bottom rafters. In the parts box you will

find a package with black rectangular adhesive rubbers. Peel back the paper strip and stick

the rubbers on to the bearers. The bearers have been marked with an etched line along the

top part of the bearer. Stick the rubber centred to the etched line. The black rubbers are to

minimise any vibration that may be caused to the sheets under extreme weather.

The bearers are now ready to be installed. The bearer is positioned onto the beams. Each

bearer has 2 holes pre drilled for each beam. These holes line up with the holes on the

beams. Place the bearer on to the beam and push the ends into the side fascia. Once in the

correct location and the holes match up, you can then proceed to fixing the bearer. Please

note that the holes are not the same width as the fixing screws. The reason is so the screws

can provide a tight fixing. The screw will be tight to begin with but will loosen once it has

cleared the required depth. The end of the bearers are also tightened with a screw at each

end into the side fascias.

The base rafters are then fixed onto the bearers. Always start from the high end (fascia) and

work back to the gutter. The base rafter is required to be hard up against the top fascia to be

water tight. The bearer has a recessed cut out to which the base rafter rests on to. Repeat the

same procedure until all the rafters have been installed.

The frame now is ready for the next stage of the roof cover.

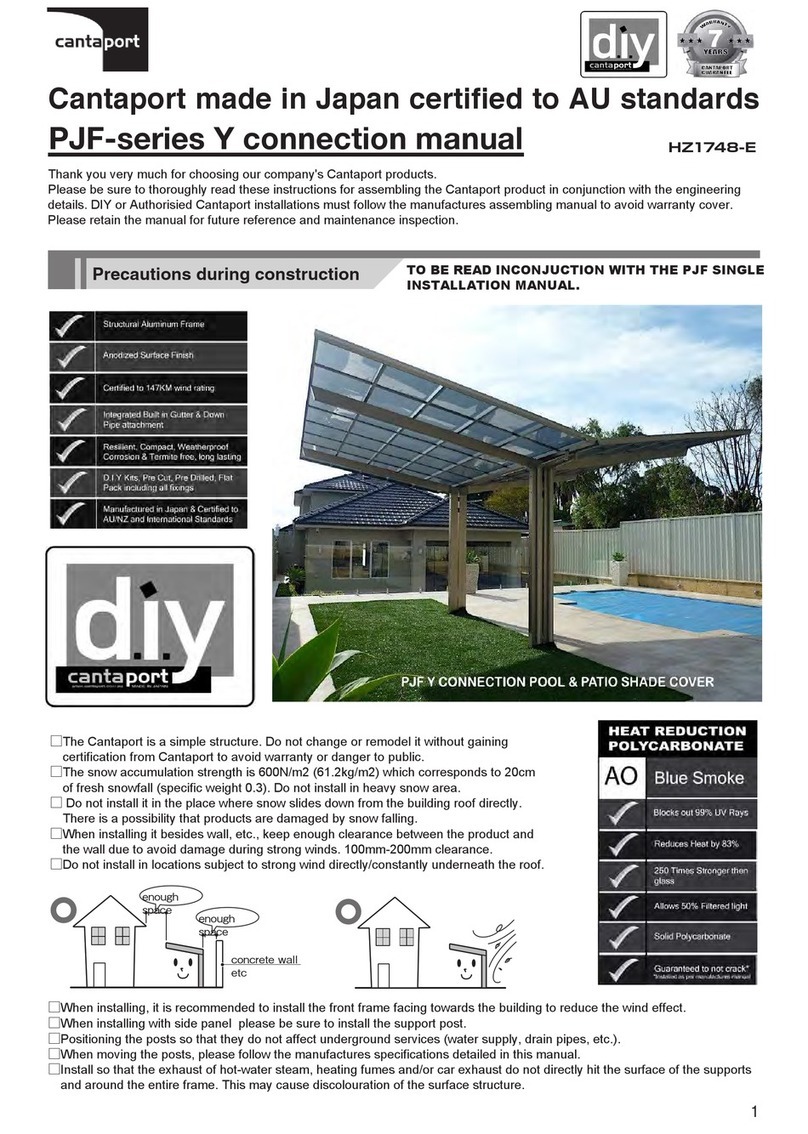

The final stage is the roof cover. The polycarbonated roof sheet blocks out 75% heat, 100%

UV rays and is considered hail proof. The sheeting is also very flexible for installation.

When installing the roof sheets, always make sure that you have access for the last sheet to

reach over to fix the cover rafter strip. If the cantaport is free standing without any structure

around the unit, you can start at either end. Should the side of the cantaport be situated against

a wall or structure with a restricted setback of less then 500mm, it is recommended that you

start from the restricted side.

The polycarbonated sheets have a protective plastic film on the top and bottom. On the

plastic film is a sticker indicating the side facing the sun. Always have that side of the sheet on

top of the cantaport. Peel the film from the top sheet after it has been installed. Always start

with the sheet inserted into the top fascia. Then let the sheet take shape over the bottom

rafters. Position the sheet equally onto the rafters and place the other end of the sheet into the

gutter. One side of the bottom rafter can then be fixed with the top rafter cover strip. Once you

have fixed all the screws into the top rafter cover strip, then continue the same procedure with

the remaining sheeting and top cover rafter strips.

The sheets should always be flat on the rafters without any gaps. The screws to the top cover

rafter strip should always be fixed correctly without any gaps. The screw is driven into a

channel that will connect the bottom and top rafter together. The process compresses and

holds the sheets together.

Finally black rubber seals are provided to be inserted to the underside of the sheeting. The

seals are pushed in between the rafters and the gutter. The down pipes provided can be

fixed to either post depending on the fall that was set out during the installation of the posts.

The protective plastic film can be removed from the sheets. Always refer to the manufactures

manual for more detailed information & instructions.