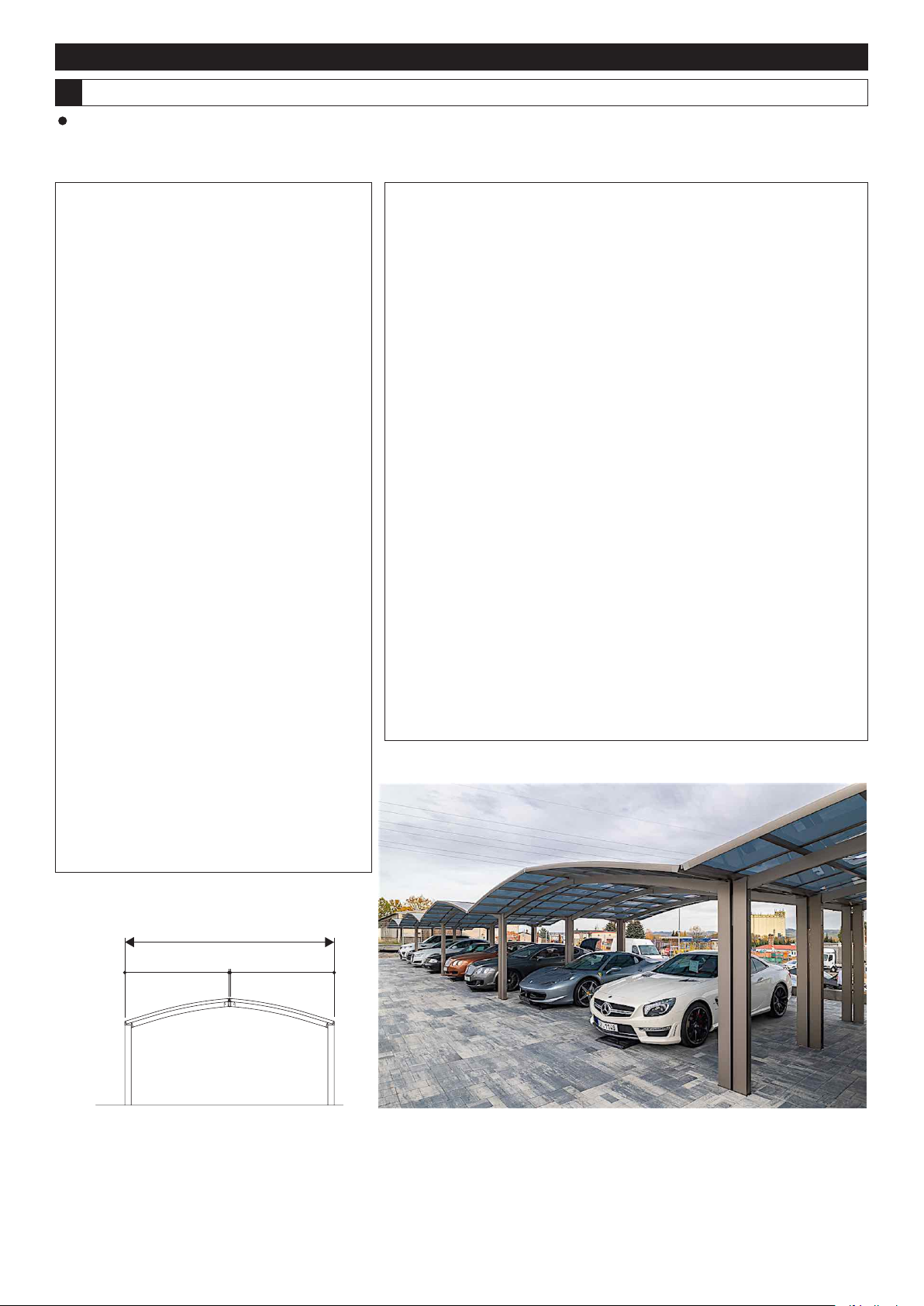

D=3000

292575

2449.2 H18

2899.2H23

3399.2H28

150

P=715

L=4312

726 726

95

8562600856

H=1800H18

H=2250H23

H=2750H28

POST=H

L=5027

726 P=715 726

1063.52900

95

1063.5

H=1800H18

H=2250H23

H=2750H28

POST=H

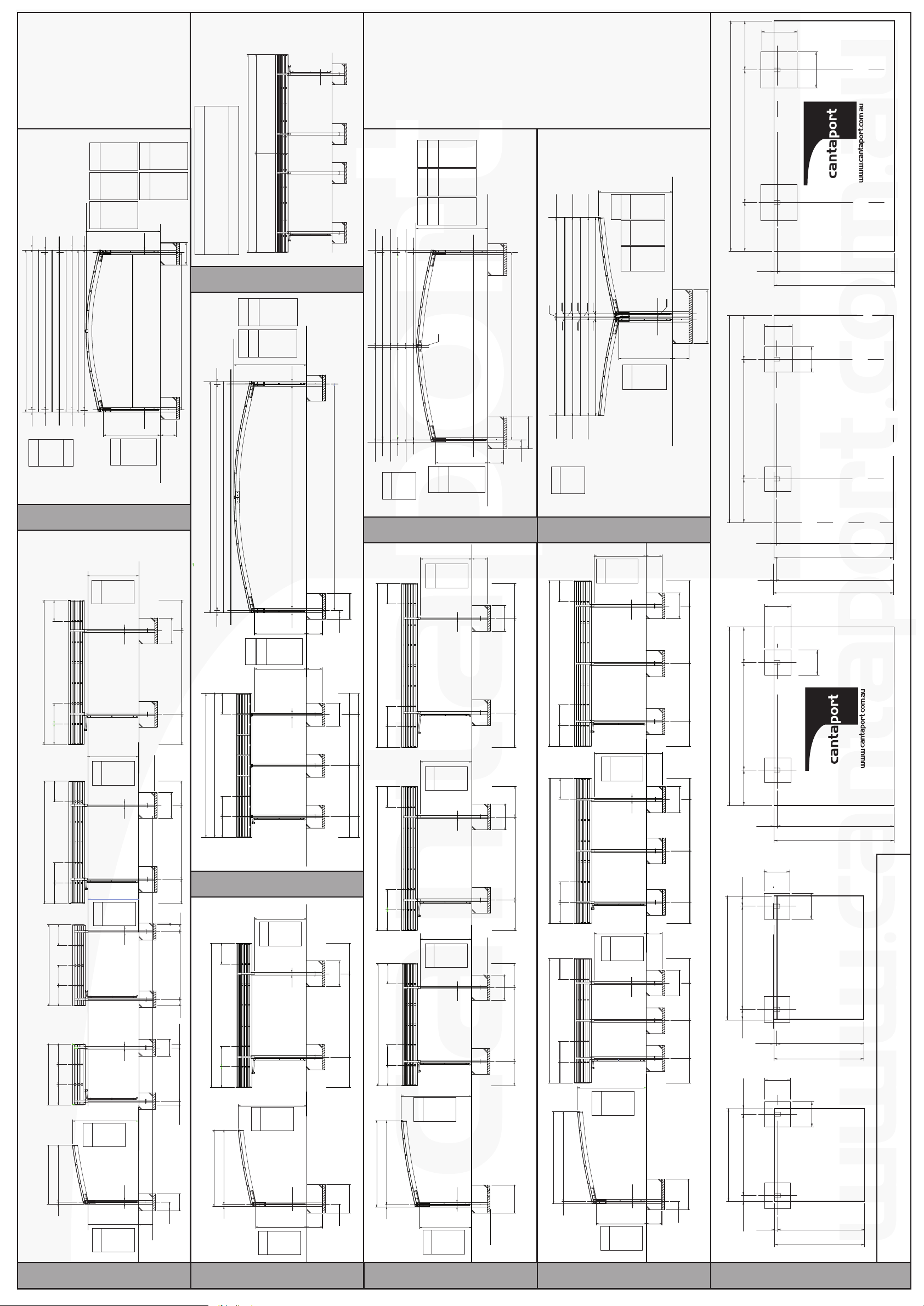

KCR-PJR4330 KCR-PJR5030 KCR-PJR5830

TOP=H

H=1800H18

H=2250H23

H=2750H28

POST=H

TOP

L=5027

726 P=715 726

1063.52900

95

1063.5

H=1800H18

H=2250H23

H=2750H28

POST=H

900

D=2700

75 2625

2422.6H18

2872.6H23

3372.6H28

900

150

300

H=1800H18

H=2250H23

H=2750H28

POST=H

KCR-PJR5027

TOP=H

TOP

900

KCR-PJR2921 KCR-PJR5021

P=715

L=4312

726 726

95

H=1800H18

H=2250H23

H=2750H28

POST=H

856

2600

856

P=715

L=2882

726 726

95

2412400241

H=1800H18

H=2250H23

H=2750H28

POST=H

715

L=2167

726 726

133.5

95

1900133.5

KCR-PJR2221 KCR-PJR4321

140

300

800

2354.6H18

2804.6H23

3304.6H28

D=2100

2030

70

L=5027

726 P=715 726

1063.5

H=1800H18

H=2250H23

H=2750H28

POST=H

2900

95

1063.5

H=1800H18

H=2250H23

H=2750H28

POST=H

TOP=H

TOP

KCR-PJR WIDE BEAM

KCR-PJR WIDE BEAM TRIPLE

800

800 900

900

H=1800H18

H=2250H23

H=2750H28

POST=H

2485.8H18

2935.8H23

3435.8H28

D30+30D27+27

2449.2H18

2899.2H23

3399.2H28

2422.6H18

2872.6H23

3372.6H28

D33+33

900

150

300

3225

75

D1=3300

35

D2=3300

D1=3000

292575

D2=3000

2925 75

W=6035

3225 75

W=6635

PostInternalD33+D33=6335

150

D33+33

D30+30

PostInternalD30+D30=5735

PostInternalD27+D27=5135

PostCenteredD33+D33=6485

PostCenteredD30+D30=5885

PostCenteredD27+D27=5285

D27+27 W=5435

HEIGHT

900

D1=2700 D2=2700

75 2625 2625 75

D=3300

3225

75

L=5027 3.3m DEPTH ONLY

726 P=715 726

P=715

L=4312 SETOUT FOR 3.3m DEPTH ONLY

726 726 P=715 726

L=5742 3.3m DEPTH ONLY

726

TOP

H=1800H18

900

150

300

738.51775

95

1775738.5

900

H=1800H18

H=2250H23

H=2750H28

POST=H

95

8561300856 1300

H=1800H18

H=2250H23

H=2750H28

POST=H

871

95

2000 2000871

900

KCR-PJR4333 KCR-PJR5033 KCR-PJR5833

H=1800H18

H=2250H23

H=2750H28

POST=H

TOP=H

2485.8H18

2935.8H23

3435.8H28

H=2250H23

H=2750H28

POST=H

NOTE: 3300 WIDE MODELS REQUIRE 3 POSTS & 3 BEAMS

D2=3300

3225

75

D1=3300 W=6638

3225

75

D2=3000D1=3000 W=6038

29252925

2625

D2=2700D1=2700

2625

W=5438

38

75 75

75 75

38

38

H=1800H18

H=2250H23

H=2750H28

1000

150150

38

2485.8H18

2935.8H23

3435.8H28

D33+33

D30+30

D27+27

W=6638

W=6038

W=5438

D30+30D27+27

2449.2H18

2899.2H23

3399.2H28

2422.6H18

2872.6H23

3372.6H28

POST=H D33+33

NOTE: 3300 WIDE MODELS REQUIRE 3 POSTS & 3 BEAMS

1000

NOTE: 3300 WIDE MODELS REQUIRE 3 POSTS & 3 BEAMS

H=1800H18

H=2250H23

H=2750H28

POST=H

2515.3H18

2965.3H23

3465.3H28

900

150 Post Internal D80=7700 150

Post Centered D80=7850

300

D=8000

7575

7850

7050

7575

D=7200

Post Internal D72=6900

Post Centered D72=7050

2430.2H18

2880.2H23

3380.2H28

D=7200

D=8000

HEIGHT

L=5027

726 P=715 726

95

738.51775738.5 1775

900

8712000 2000871

W=5742

W=5027

L=5742

900 NOTE: WIDE BEAM TRIPLE MODELS REQUIRE 3 POSTS & 3 BEAMS

900

140 140

2374.1H18

2824.1H23

3324.1H28

2340.7H18

2790.7H23

3290.7H28

WB=51 WB=54 WB=60

H=1800H18

H=2250H23

H=2750H28

POST=H

Post Centered WB 51=4951.2

Post Centered WB 54=5266

Post Centered WB 60=5855.4

2436.8H18

2886.8H23

3386.8H28

4951.2 ( WB-51) 70

D=5406 (WB=54)

5266 (WB=54) 70

D=5091.2 (WB=51)

70

70

D=5995.4 (WB=60)

70

5855.4 (WB=60)

70

D=4815.4 (WB=48)

70

4675.4 (WB=48)

70

D=4223.2 (WB=42)

70

4083.2 (WB=42)

70

Post Internal WB 51=4811.2

Post Internal WB 54=5126

Post Internal WB 60=5715.4

Post Internal WB 42=3943.2

Post Internal WB 48=4535.4

Post Centered WB 42=3943.2

Post Centered WB 48=4675.4

4 POSTS

WB=48

2311.4H18

2761.4 H23

3261.4 H28

WB=42

2248.4H18

2698.4H23

3198.4H28

L=4312

L=5027

LENGTH

L=5742

L=4312

L=5027

LENGTH

L=5742

L=4312

L=5027

LENGTH

L=5742

HEIGHT

HEIGHT

HEIGHT

HEIGHT HEIGHT

HEIGHT

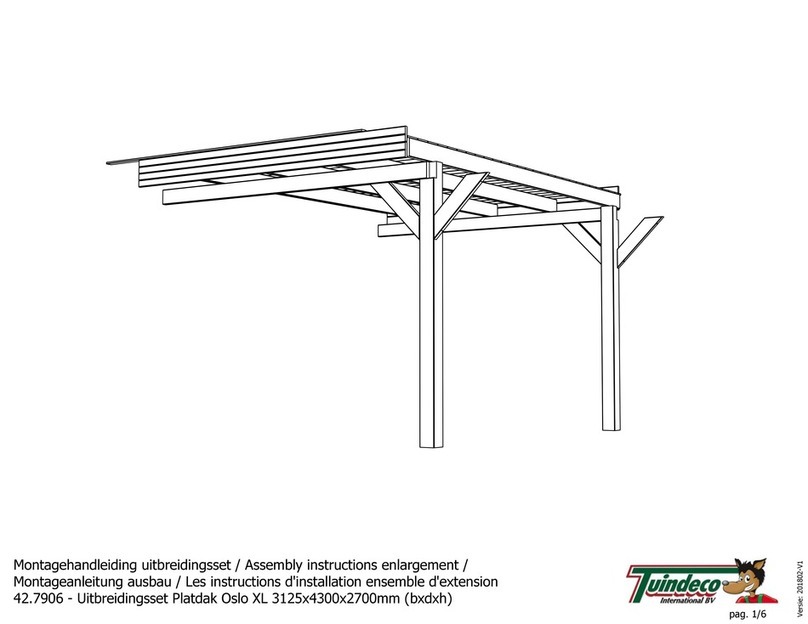

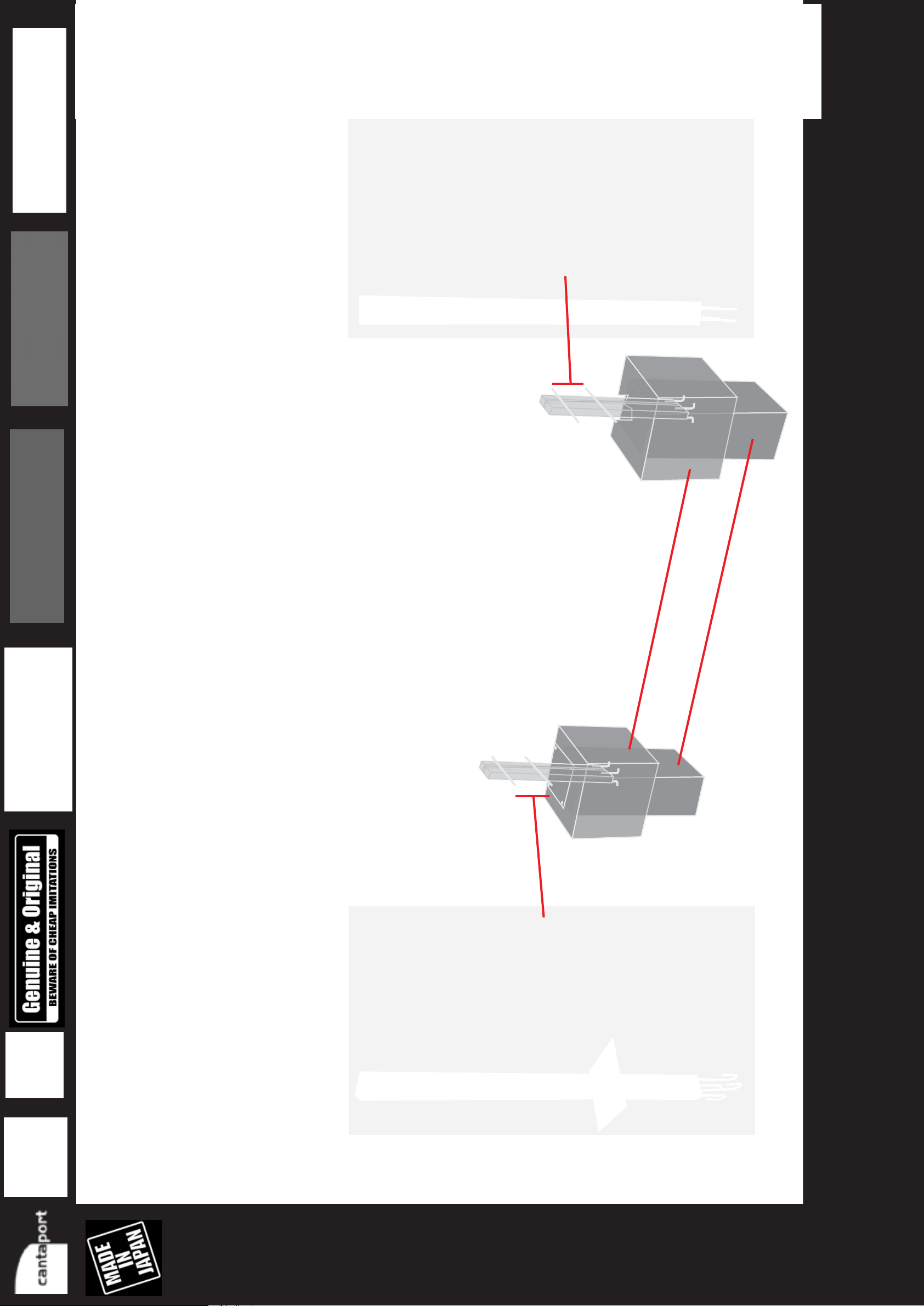

KCR-PJR M CONNECTION

KCR-PJR Y CONNECTION

KCR-PJR DEPTH 2100KCR-PJR DEPTH 2700

KCR-PJR DEPTH 3000KCR-PJR DEPTH 3300

KCR-PJR Y CONNECTION KCR-PJR M CONNECTION

KCR-PJR WIDE BEAM TRIPLE

KCR-PJR WIDE BEAM

KCR-PJR INLINE

DEPTH & SETOUT AS PER INDIVIDUAL SERIES

KCR-PJR43 L43+43 = 4312+4312=L 8602

KCR-PJR50 L50+50 = 5027+5027=L10032

LENGTH

KCR-PJR57 L57+57 = 5742+5742=L11462

OVERALL LENGTH = L+L

95

L L

NOTE: 3300 WIDE MODELS REQUIRE 3 POSTS & 3 BEAMS

P=715 726

1221

95

1221

W=5742

726

3300

H=1800H18

H=2250H23

H=2750H28

POST=H

133.5133.5

600

1900

L=2167

600

D=2100

702030

241 2412400

L=2882

600

600

D=2100

702030

856 8562600

L=4312

900

900

D=3000 [3300]

752925 [3225]

1063.5 1063.52900

L=5027

900

900

D=2100

702030

3225 [2975] {2675} 75

D=3300 [3000] {2700}

75

1221

2925 [3225]

D=3000 [3300]

900

1221

L=5742

3300

900

900

900

900

900

900

KCR-PJRPLAN LAYOUT

L=22 L=29

L=43 L=50 L=57

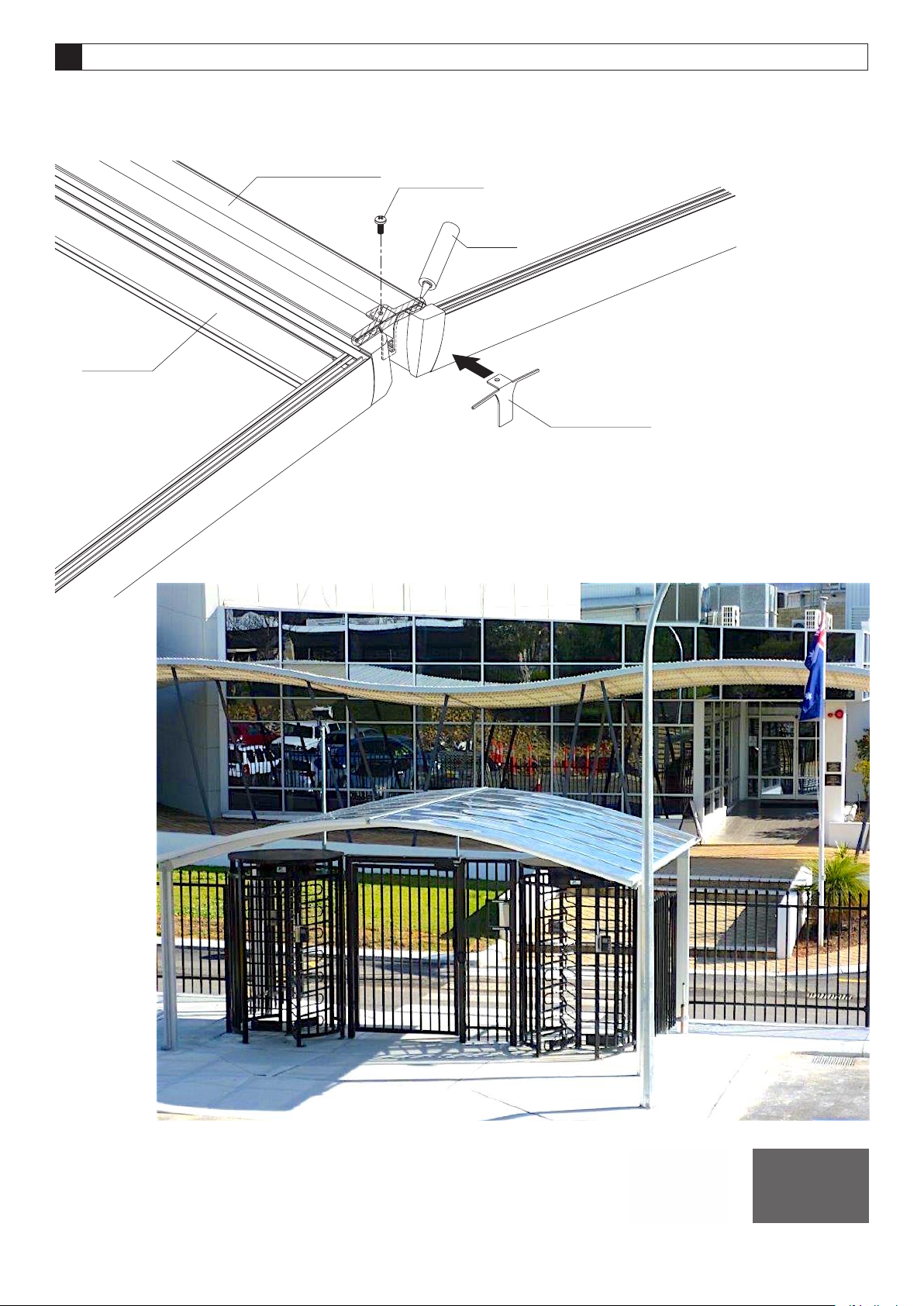

General Notes :

1. Engineering drawings to be read

in conjuction with all architectural and

other specification drawings.

2. Any discrepancies shall be referred

to the engineer for confirmation prior

to commencing construction.

3. For setting out dimensions refer to

architectural drawings.No dimensions

to be obtained by scaling drawings.

4. All dimensions and levels to be

checked on site prior to commencing

any work.

5. All work to comply with the latest

Australian Standards and Buildng

Codes of Australia

6. Installation to be installed in

accordance with manufacturer's

printed assemling manual.

Foundations

1. All soil testing to be carried out by

the enginner soil type and conditions.

2. Remove all topsoil containing

vegetation & deletrious fill materail

from the building site.

Concrete Notes :

1. All concrete shall be in accordance

with the concrete structure code

AS 3600.

2. Blended cement (type GB) shall

conform with AS 3972 3. Water must

not be added to the mix to increase

the slump at any time.

3. Concrete shall be supplied by an

approved pre-mixed company and

conform to the following unless noted

otherwise :

GRADE SLUMP MAX. AGG.

FOOTINGS N20 80mm 30mm

METAL WORK NOTES :

1. All workmanship and materials

shall be in Accordance with

- AS/NZS 1866:1977-Aluminium and

Aluminium Alloys

- AS 1400-1998 Steel Structures

-AS/NZS 1665:2004 Welding Of

Aluminium Structures

- AS 1554.1 PT1 - Welding Of Steel

Structures

2. All hollow sections to be fully sealed

with 2mm plates, minimum, U.N.O

3. Erection of metal work shall be

commenced with braced bay and

erector shall provide all temporary

bracing required for the safe

completion of the work.

4. All bolts/screws/washers types and

their treatment of, is to comply with

all relevent australian standards

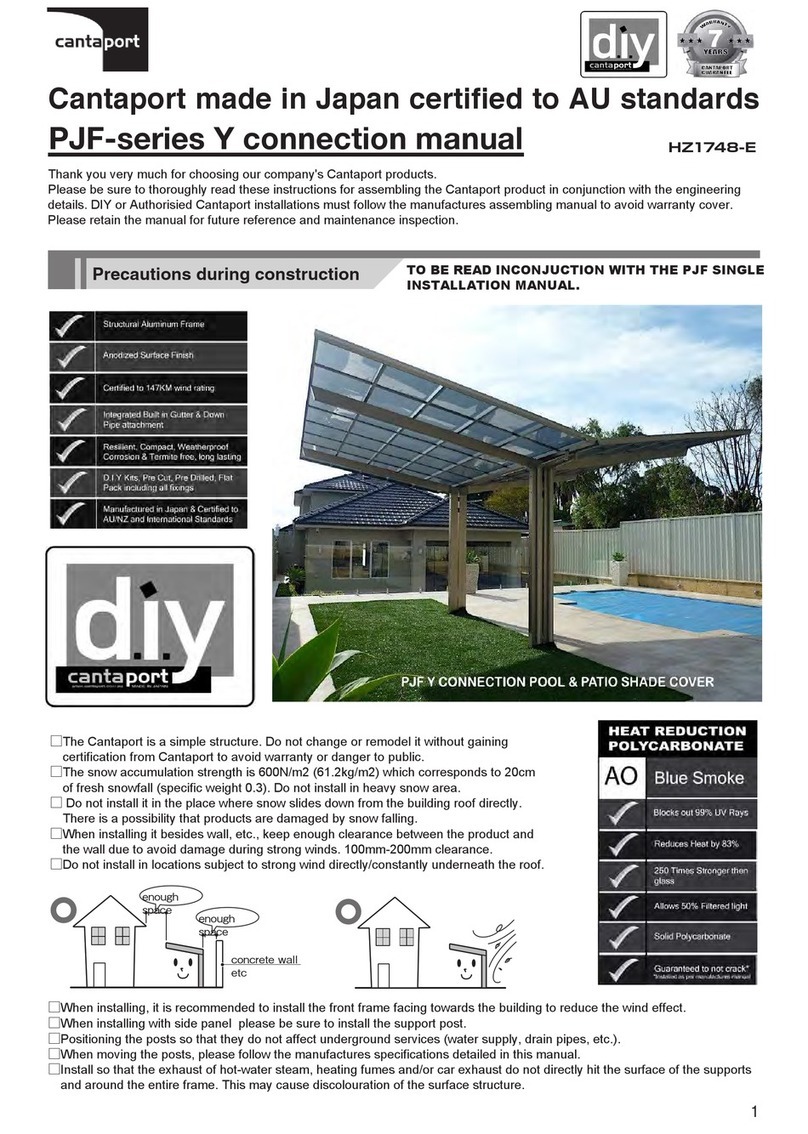

CERTIFICATION OF CANTAPORT KCR-PJR SERIES: THE CANTAPORT IS CERTIFIED FOR REGION A &TERRAIN CATEGORY2&3.

THE CANTAPORT IS DESIGNED ONLY WHEN THE POST IS BUILT IN THE FOOTINGS, BUT NOT ON CONCRETE SURFACES. THE

CANTAPORT STRUCTURE IS STUCTURALLY CAPABLE OF SUPPORTING THE DESIGN LOADS IN ACCORDANCE WITH ALL

RELEVENT AUSTRALIAN STANDARDS.

990000

900 900

900

900

900

900

900

900