HZ1747-E

1

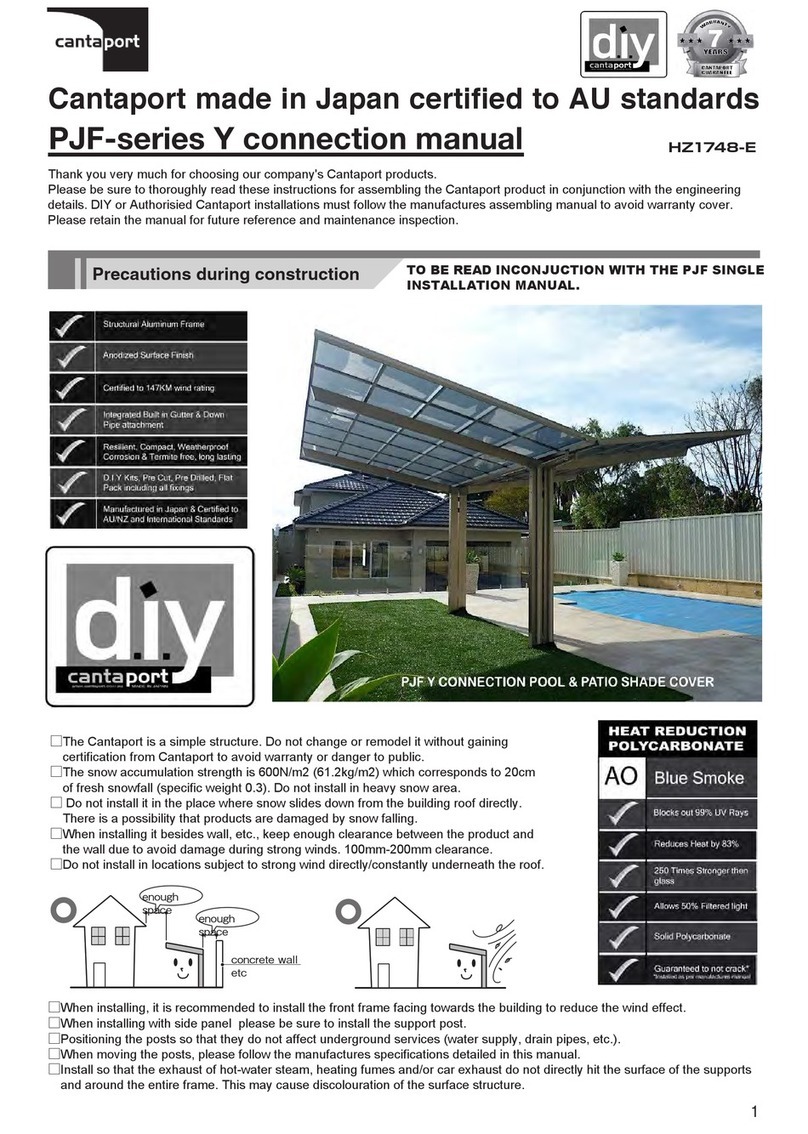

Cantaport made in Japan certified to AU standards

PJF-series M connection manual

Thank you very much for choosing our company's Cantaport products.

Please be sure to thoroughly read these instructions for assembling the Cantaport product in conjunction with the engineering

details. DIY or Authorisied Cantaport installations must follow the manufactures assembling manual to avoid warranty cover.

Please retain the manual for future reference and maintenance inspection.

Precautions during construction

□The Cantaport is a simple structure. Do not change or remodel it without gaining

certification from Cantaport to avoid warranty or danger to public.

□The snow accumulation strength is 600N/m2 (61.2kg/m2) which corresponds to 20cm

of fresh snowfall (specific weight 0.3). Do not install in heavy snow area.

□Do not install it in the place where snow slides down from the building roof directly.

There is a possibility that products are damaged by snow falling.

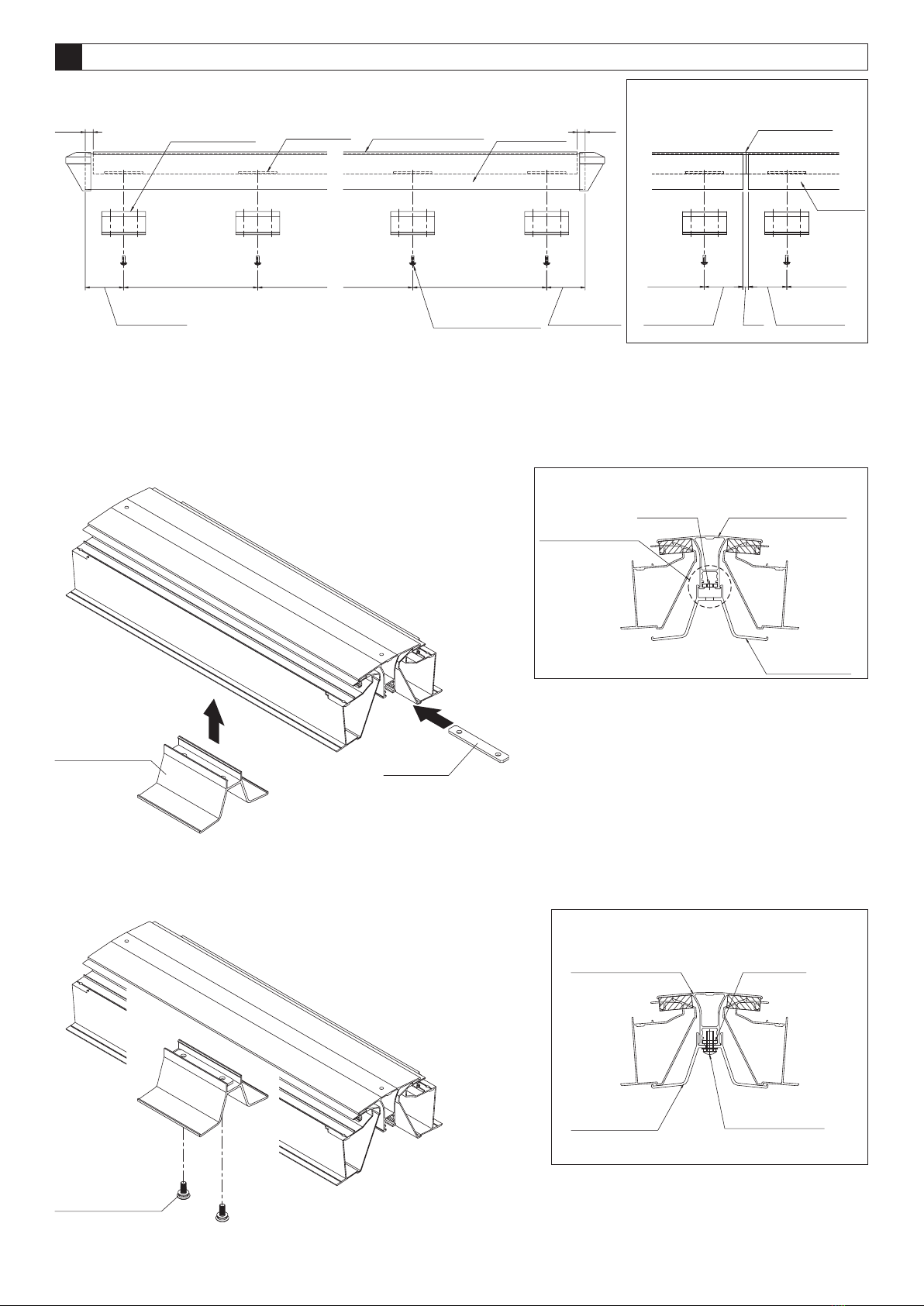

□When installing it besides wall, etc., keep enough clearance between the product and

the wall due to avoid damage during strong winds. 100mm-200mm clearance.

□Do not install in locations subject to strong wind directly/constantly underneath the roof.

□When installing, it is recommended to install the front frame facing towards the building to reduce the wind effect.

□When installing with side panel please be sure to install the support post.

□Positioning the posts so that they do not affect underground services (water supply, drain pipes, etc.).

□When moving the posts, please follow the manufactures specifications detailed in this manual.

□Install so that the exhaust of hot-water steam, heating fumes and/or car exhaust do not directly hit the surface of the supports

and around the entire frame. This may cause discolouration of the surface structure.

enough

space enough

space

concretewall

etc

TO BE READ INCONJUCTION WITH THE PJR SINGLE

INSTALLATION MANUAL.