Contents

Each HDZ comes with the following hardware as standard (this is all required to attach it to your Shapeoko). As of

October the only items you need to transfer from your existing X/Z is the homing switches, X/Z motors, spindle.motor

and mount.

● 1 x EZTram Dewalt/Makita/Carbide Compact Router spindle mounting plate

● 2 x M5 18mm screws for the top of EZTram plate

● 2 x M5 10mm screws for the bottom of EZTram plate

● 2 x Eccentric spacer for EZTram

● Shaft coupler

● 4 x 40mm Z motor supports

● 4 x 25mm X motor supports

● 8 x 10mm M5 Screws for motor stand-offs

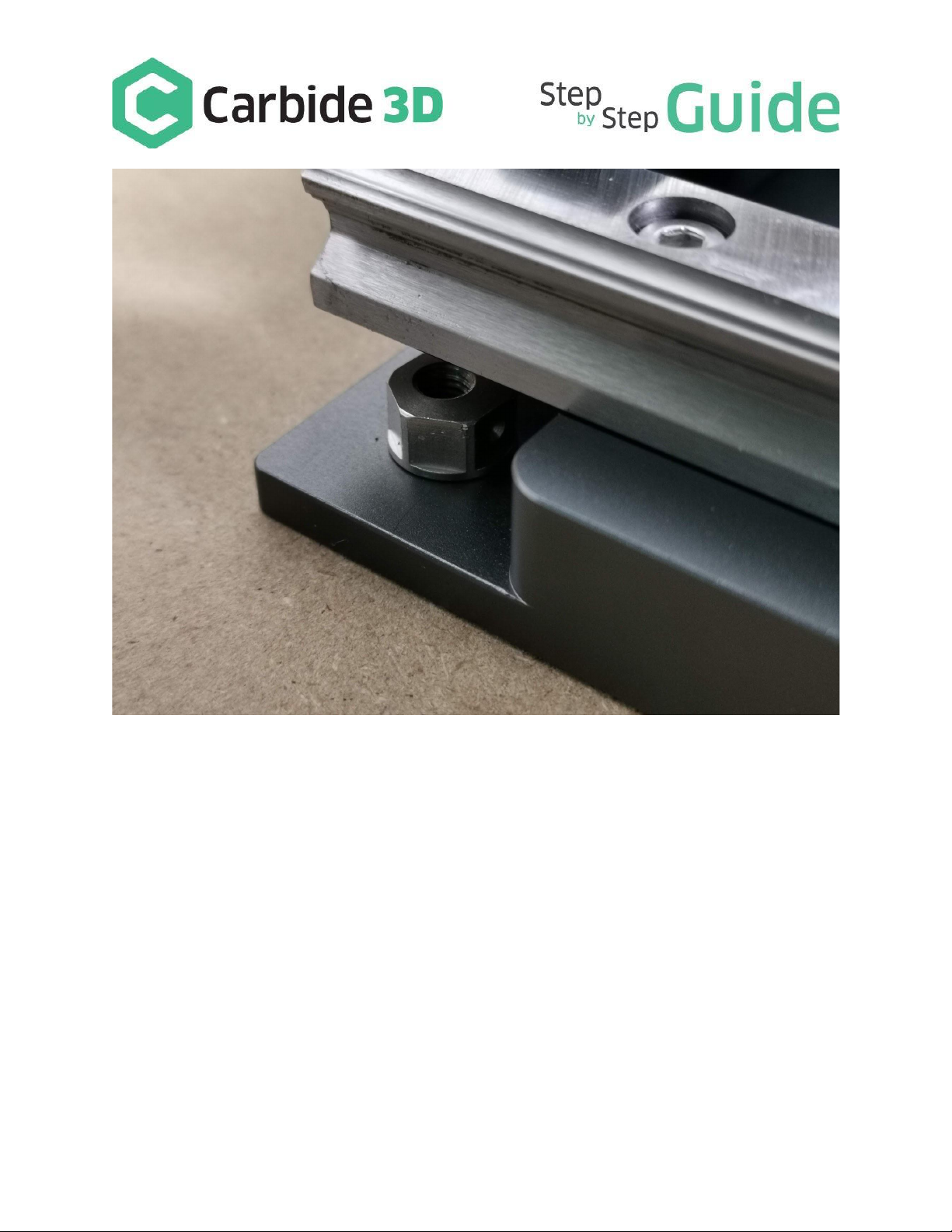

● 2 x HD Eccentric nuts

● 4 x Replacement V-wheel

● 4 x V-wheel shim

● 4 x M5 x 25mm Screw for V-wheels

● 2 x M8 30mm X pulley screws

● 2 x M8 Washer

● 2 x M8 Spacer

● 4 x M8 guide bearings

● 4 x Black sledge - this is used if you have to remove a carriage

Removal

Your first step is to remove your existing X/Z carriage from your Shapeoko. To do this;

● Turn off your machine and unplug it.

● Disconnect the router or spindle and remove it from the spindle mount.

● Remove one side of your X axis belt tensioners and place the belt from the X axis to one side.

● Label, then disconnect Z and X motors. Remove your Z and X Homing switches from the Z/X carriage along

with the drag chain bracket.

● To remove the axis loosen and remove your lower eccentric nuts and bottom V-wheels from the bottom of the

axis and remove.

● Your Z/X can now be lifted off your machine.

● Remove the X and Z motors from the old axis and disconnect.

The Z motor will have a gear pulley on it. Loosen the two small grub screws. In some cases this will still be hard to slide

off. We recommend using a screwdriver or needle nose pliers or the back of a claw hammer to lever it off. Once the

motors are off, also remove the spindle mount and screws.