Carefree of Colorado Service Manual MARQUEE

052549-301 5

MOTOR REPLACEMENT

This operation can be done while the awning is mounted on the RV. Use care to not damage the walls etc.

1. Disconnect power to the awning.

2. If the awning is extended: (Refer to Detail A) Carefully push the lead rail

toward the case so that the arms collapse. While holding the lead rail in this

position, firmly tie the elbows of the spring arms together. Use a minimum 1/2"

rope - do not use bungee cords. When tying the rope, use a non-slip knot such

as a square knot or equivalent.

3. If the awning is closed: Firmly brace the lead rail in the closed position. A second person can hold the lead

rail steady during the disassembly process.

CAUTION

FAILURE TO SECURE THE LEAD RAIL AS DESCRIBED WILL ALLOW THE SPRING ARMS TO UNEXPECTANTLY

EXTEND OUT POSSIBLY CAUSING PERSONAL INJURY AND DAMAGE TO THE AWNING.

4. Remove the 4 screws holding the end cap to the case, do not remove the motor attach screws at this time.

5. Pull the end cap and motor partially out from

the awning case. CAUTIONS

WHEN PULLING THE MOTOR OUT OF THE CASE,THE

SERVICING TECHNICIAN MUST USE CARE TO NOT

BREAK OR DAMAGE THE MOTOR CABLES.

WHEN PULLING THE MOTOR,DO NOT LET THE

ROLLBAR COME OUT MORE THAN 1"; OTHERWISE THE

ROLLBAR IDLER WILL DISENGAGE FROM THE

OPPOSITE END PLATE.IF THIS OCCURS,REINSERT

THE IDLER ONTO THE ENDPLATE BEFORE CONTINUING.

6. Disconnect the motor wires from inside the coach and pull out or clip the motor wires. If cutting the

motor wires be sure to leave enough wire that can be stripped and spliced.

7. Pull the motor, crown, roller bearing and drive hub out of the roll bar and remove the attaching screws holding

the motor to the end cap. Make note of the motor orientation on the end cap.

NOTE: If the awning is closed when the motor is removed the spring arms will try to open.

Support the roll bar and allow the awning to open slowly then secure the arms by tying

the elbows together as described in step 2.

8. Remove the crown, roller bearing and drive hub from the old motor and install on the new motor.

9. Attach the new motor to the end plate paying attention to match the orientation from the old motor.

NOTE: To improve the motor mounting, the motor screws have been lengthened to increase the

screw thread engagement. The original screws were M4 x 20mm. Current production and

replacement screws are M4 x 25mm. The motor replacement kit (R001531) includes new

screws and washers.

•When replacing a motor that is attached using the shorter screws, discard the existing

screws and attach the motor using the longer screws and the washers included with the

motor replacement kit.

•The current production end caps have been upgraded to use the longer screw. If replacing

a motor with the longer screws, DO NOT use the washers. The motor is attached with just

the screws.

10. Partially slide the new motor assembly into the roll bar. Ensure that the motor drive gear and crown are

properly seated inside the roll bar.

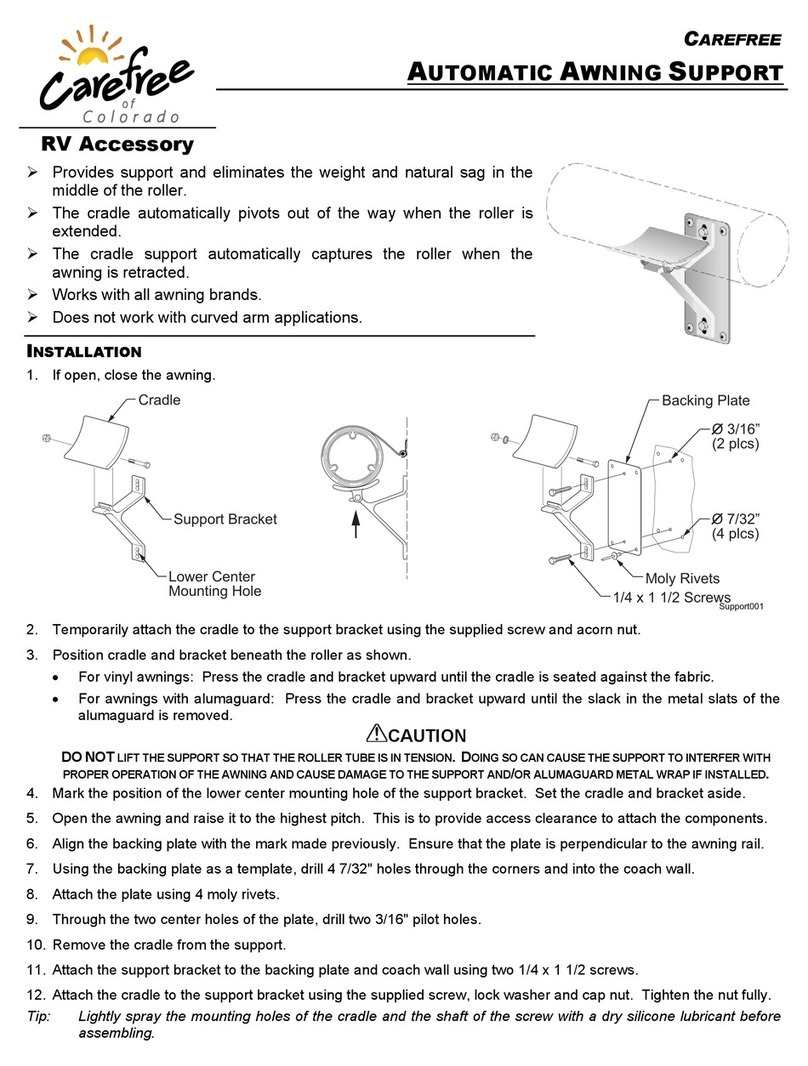

Marquee012

Spring Arms

Firmly Tie

Elbows Together

Figure 4. Tying the Arms.

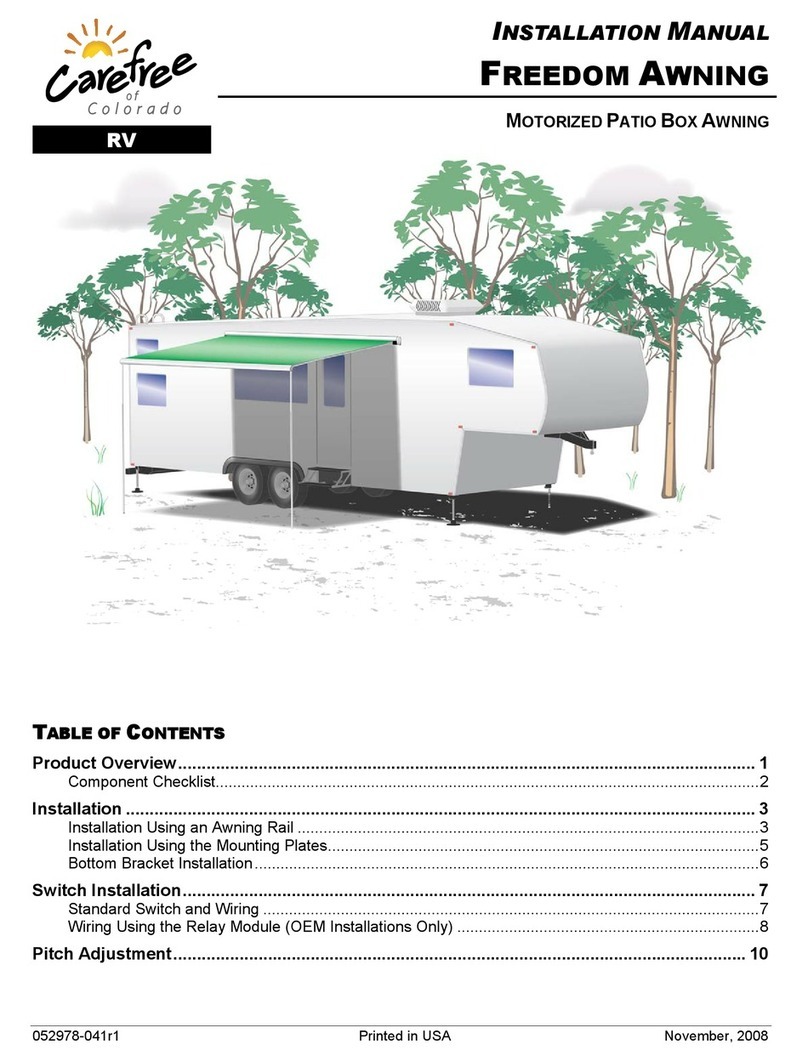

Marquee012

Motor

Crown

Roller Bearing

Drive Hub

Motor

Screws

Wall Closeout

End Cap

Figure 5. Replacing the Motor.