5

ENG

rtM +0400030EN - rel. 1.3 - 02.03.2017

The installation guide is designed to offer practical help to the installer.

It describes the installation of the rTM SE system, explaining all the steps

required until completion, and highlighting all the procedures that must

be performed to ensure best results, from the preliminary site inspection

up to installation and maintenance.

For further details and technical information see the rTM SE user manual

(code +0300030IT).

The following steps are recommended for correct installation of the rTM

SE system:

- site inspection;

- selection of the devices, installation plan and quotation;

- system configuration;

- installation;

- commissioning.

1. INTRODUCTION

2. SYSTEM COMPOSITION

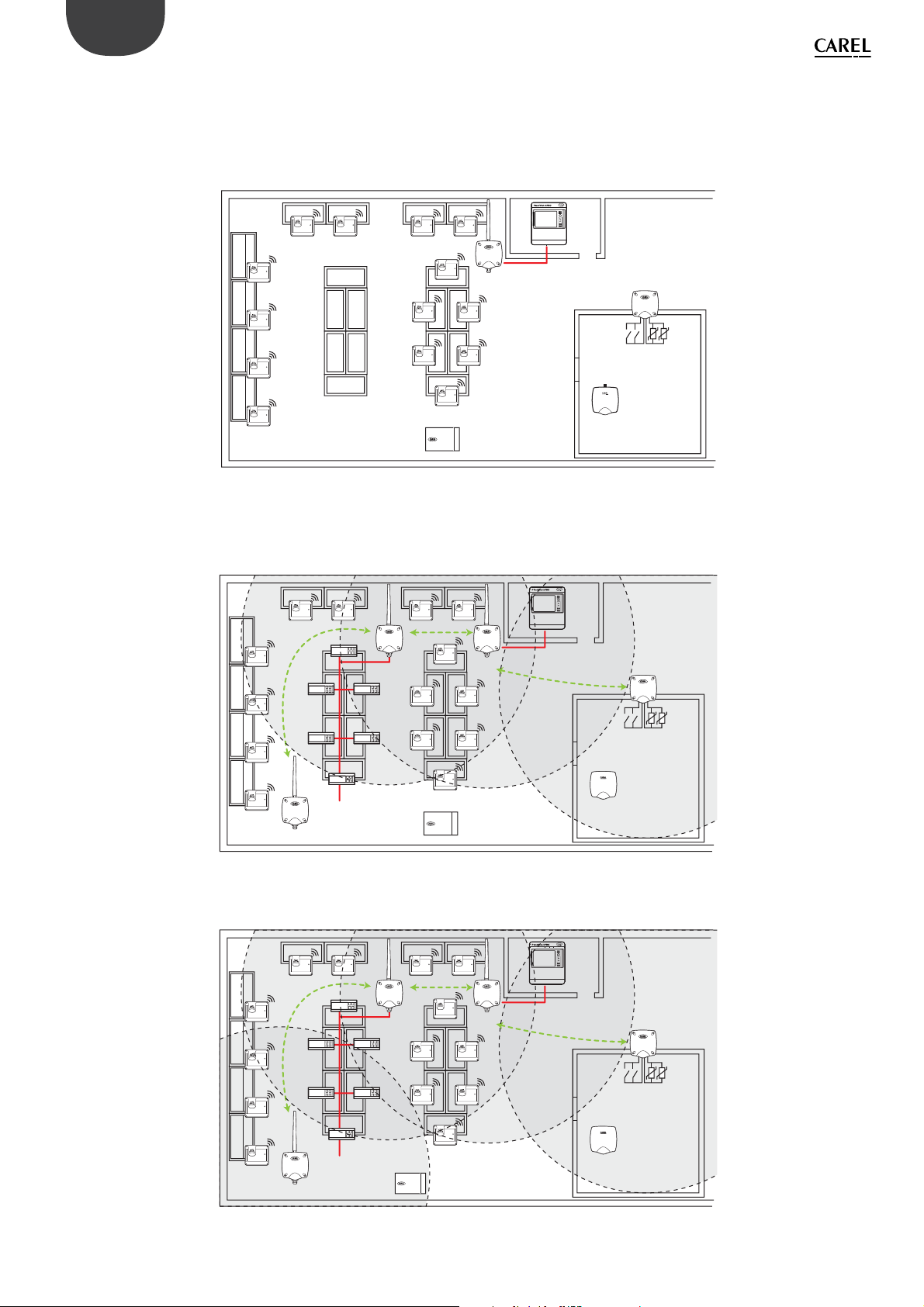

The rTM SE system is made up of devices that provide the ZigBee™

wireless infrastructure, i.e. Access Points, Routers, Bridges and other

components with specific functions, such as sensors, actuators, counters

electricity meters, and so on. To identify the best components for the

design requirements from those described below, the following aspects

need to be considered:

• what needs to be measured, monitored and controlled;

• intensity of use (choice between battery or mains powered devices);

• installation site (accessibility to the point of measurement, obstacles

blocking the wireless signal).

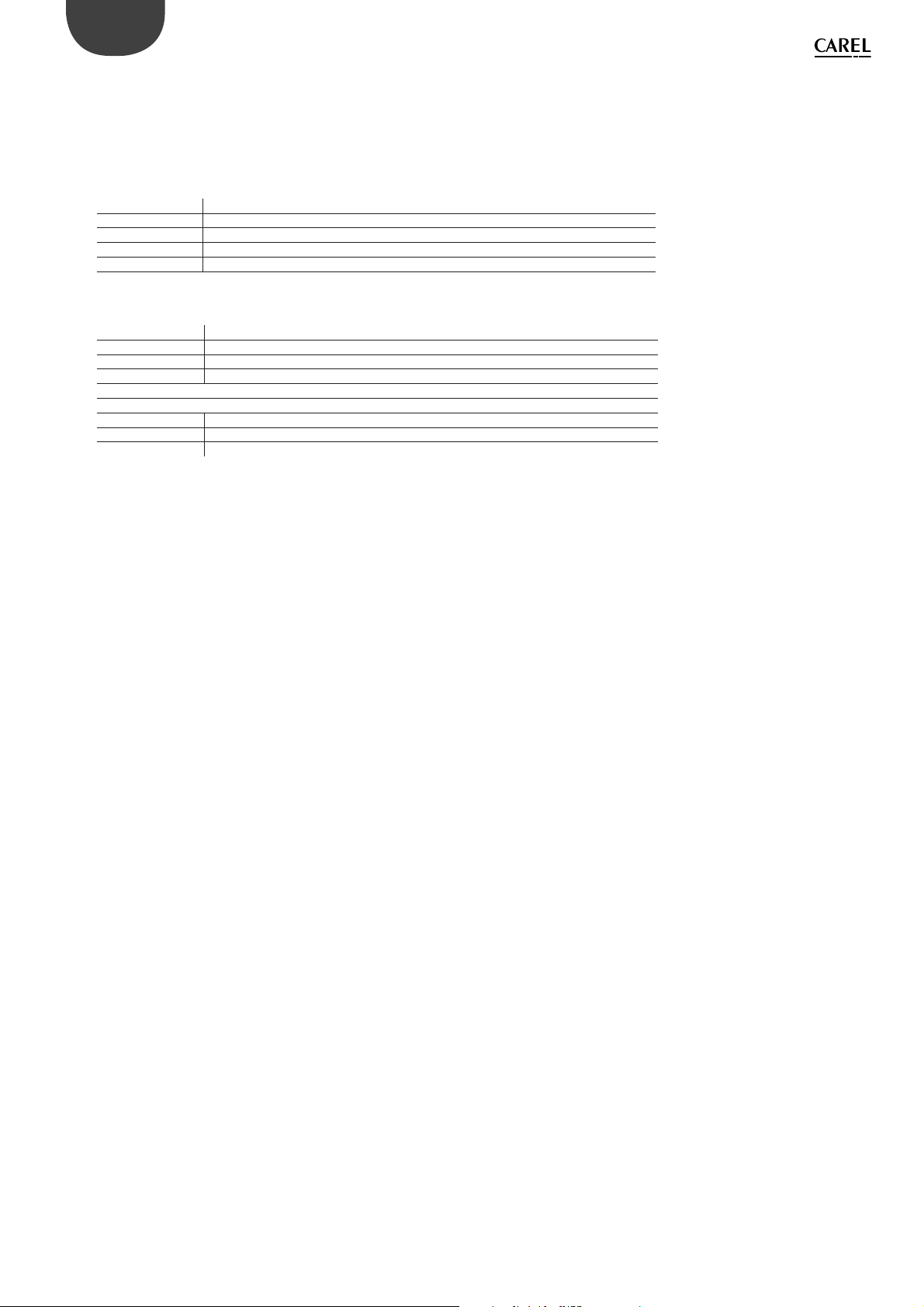

rTM SE system wireless sensors

• BP SE sensor code WS01U01M00 (powered by long life battery)

– 1 Temperature (built-in probe)

– IP65 sealed case, no wiring required.

– Suggested application: showcases, HACCP procedures.

• EP SE sensor code WS01W02M00 (powered by long life battery)

– 2 Temperatures

– 2 digital inputs

– The temperature values are measured by CAREL NTC probes

(supplied separately).

– The digital inputs can monitor defrost status, door open, light on,

external alarm etc. (wiring to voltage-free contacts needed).

– Suggested application: cold rooms, refrigerated cabinets etc.

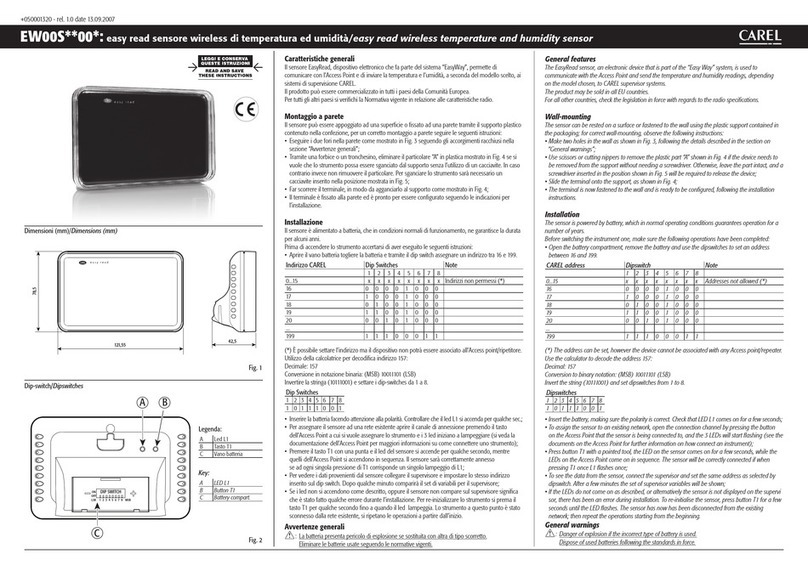

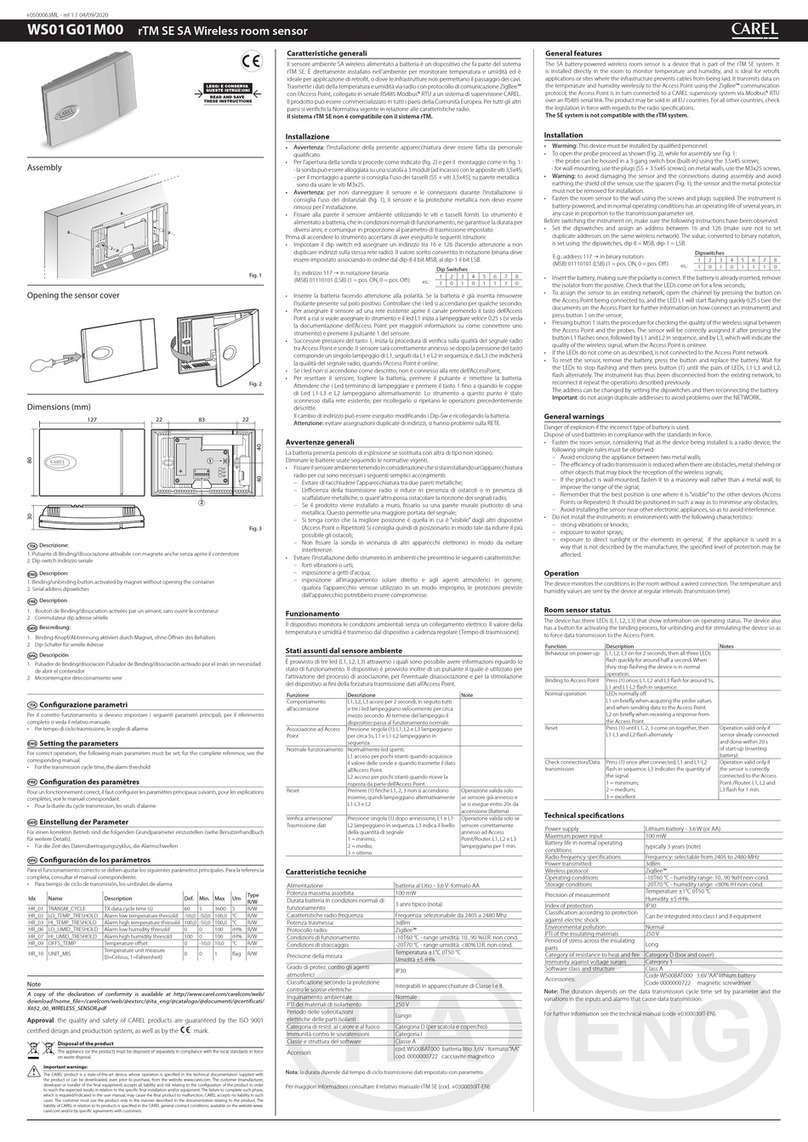

• SA room sensor code WS01G01M00 (powered by long life battery)

– Room temperature and humidity

– Wall-mounted, appearance suitable for residential uses. No wiring

required.

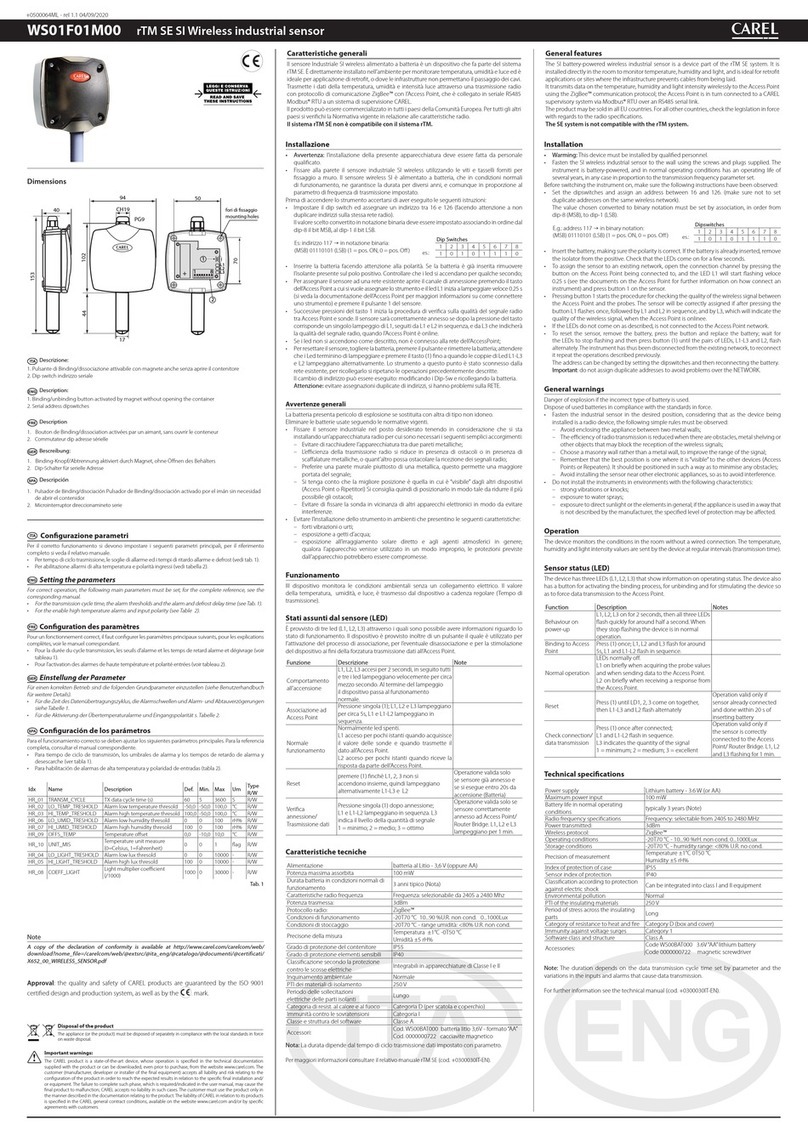

• SI sensor for industrial environments code WS01F01M00 (powered by

long life battery)

– Room temperature, humidity and light sensor

– Wall-mounted, appearance suitable for residential uses. No wiring

required.

rTM SE system ZigBee™ wireless structure

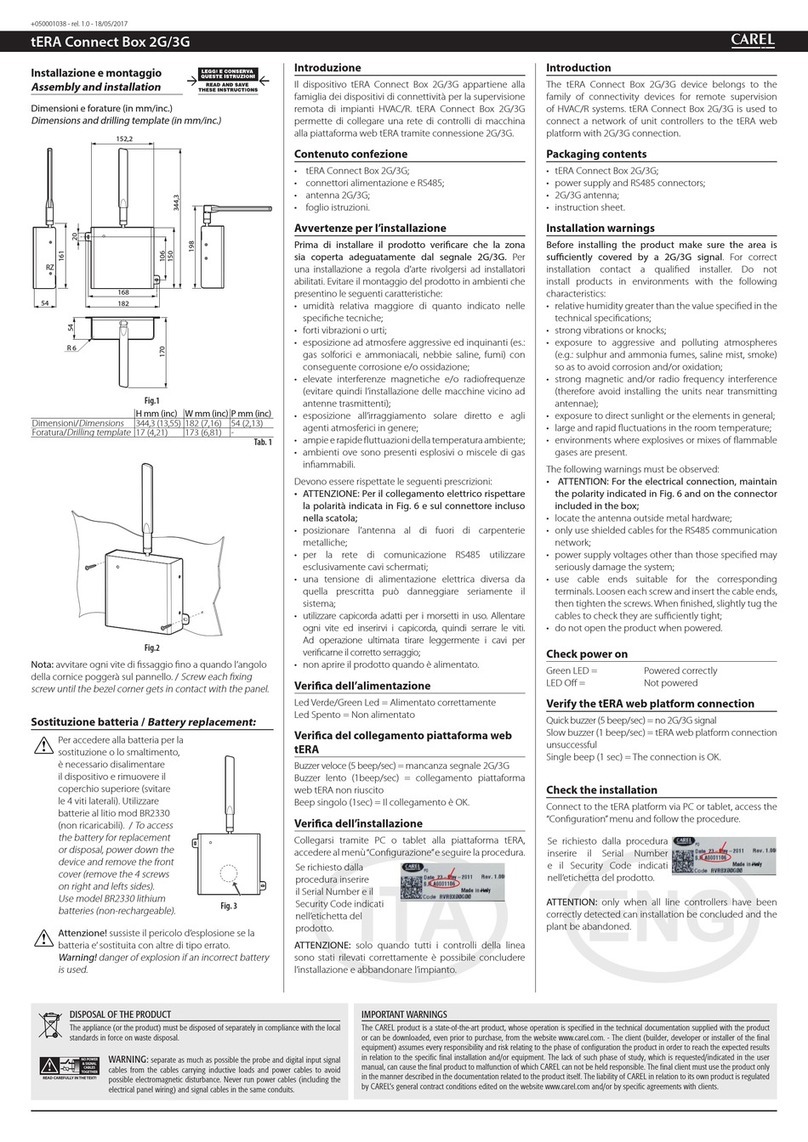

• Access Point: ZigBee™ wireless receiver / transmitter

– code WS01AB2M20 (powered at 12 Vac/dc).

– This is the connection point between the rTM SE system wireless

components and the wired data line to a Carel supervisor or BMS

(Building Management System), with Modbus® protocol over RS485.

– Each device in the rTM SE system is, during configuration, assigned

to a specific Access Point and consequently to a specific wireless

network.

– Up to 7 Access Points can be connected to each serial line.

Below is a detailed description of the operations that must be carried out

for correct maintenance.

Important: configuration and installation of the rTM SE system

must be performed by qualified personnel. Prior training at CAREL is

suggested.

• Router: ZigBee™ wireless repeater

– code WS01RC1M20 (powered at 230 Vac).

– Repeating the wireless signals means:

– larger surfaces and greater distances can be covered between

Access Point and sensors;

– obstacles or unfavourable conditions for wireless coverage can be

overcome;

– the network of sensors can be extended to include a greater number

of units.

Other rTM SE devices with Router function incorporated

The rTM SE system also allows other devices, fitted with external power

supply, to act as wireless repeaters, incorporating the Router function.

– EP1 router sensor code WS01VB2M10 (powered at 12/24 Vac/dc).

– Same functions as the EP SE sensor, integrating the Router function.

– 2 NTC temperature probes, 2 digital inputs (see EP SE sensor).

– The external power supply makes it useful for applications that

require very frequent transmissions (fast switching cycles of the

digital inputs that require wireless transmission), e.g.: CAREL“wireless

floating suction” system to reduce power consumption, adapting

the operation of the compressor rack to the load.

• Router-Bridge code WS01RB2M20 (powered at 12/24 Vac/dc)

– Completely transparently replaces a section of RS485 cable using

ZigBee™ wireless transmission between Router-Bridge and Access

Point. For the communication limits see the technical manual.

– A Router-Bridge can be connected to generic Modbus devices wired

to the Router-Bridge RS485 sub-network.

– These devices, physically connected to the Router-Bridge only, are

thus “detected” by the CAREL supervisor or the BMS as if they were

physically connected to the same RS485 network as the Access Point.

– Suggested application: Modbus® systems where it is difficult or too

costly to install sections of RS485 serial cables

• RA router-actuator code WS01H02M20 (powered at 12 Vac)

– This is an I/O expansion module with 2 relay outputs, 2 digital inputs

and 1 input for NTC temperature probe (10K@25°C). It includes a

configurable heating/cooling thermostat function.

– There are numerous applications for this device, which adds controls

and actuators to any position in the space covered by the rTM SE

wireless system.

• Code WS01E02M00 rTM SE CI WIRELESS COUNTERS (powered by long

life battery)

– Suitable for measuring power consumption or volume flows (gas,

water etc.) based on pulse signals generated by standard devices.

Can be used with any Modbus® system connected to the associated

Access Point.

– 2 pulse counter digital inputs

– 2 NTC temperature inputs (10K@25°C)