+050004242 - rel. 1.1 - 07.01.2021

CAREL INDUSTRIES HQs

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy)

T

el.

(+39)

0499716611

–

Fax

(+39)

0499716600

–

http://www

.carel.com

–

e-mail:

[email protected]CAREL si riserva la possibilità di apportare modifiche o cambiamenti ai propri prodotti senza alcun preavviso.

CAREL reserves the right to modify the features of its products without prior notice.

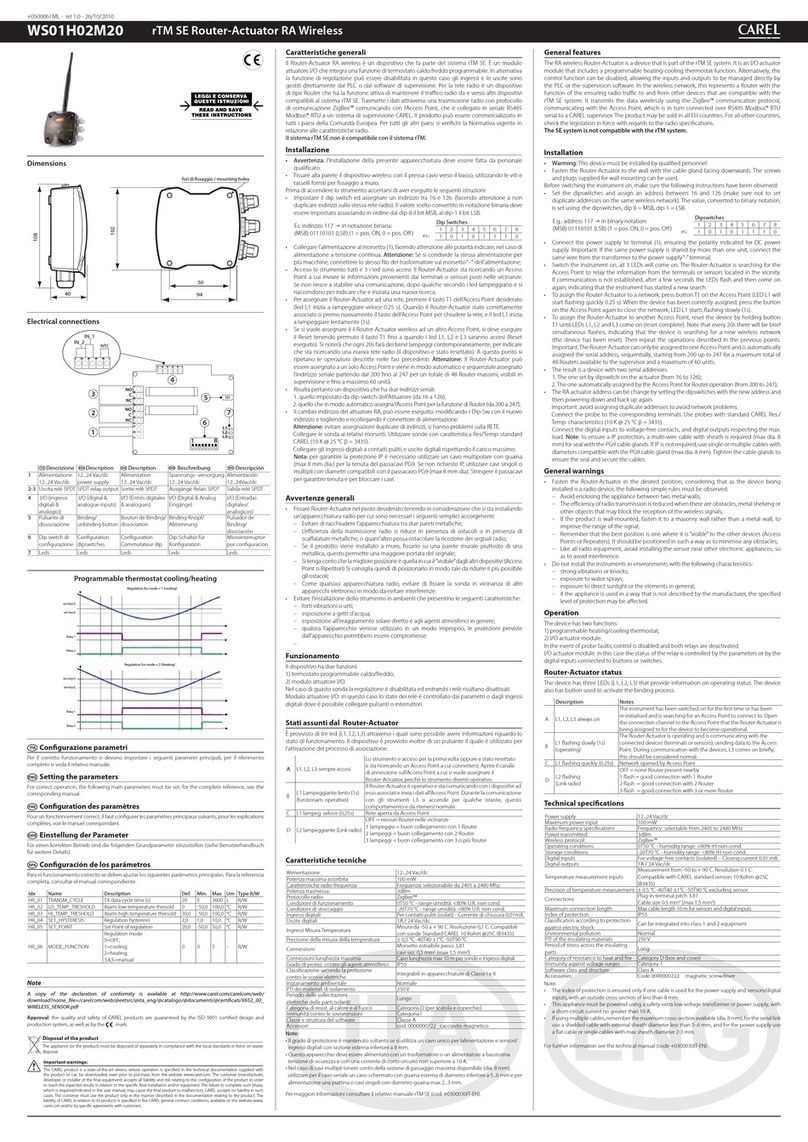

Dimensions (mm)

71x29

10

3

74

81

36

58

65,29

28.5

Panel mounting

Pozidriv type

do not tighten

excessively

Front (with 2 screws ø 2,5x12 mm)

Rear (with 2 quick-t side brackets)

Fig. 1

Fig. 2

12

PUSH

Fig. 3

PJS8* is a microprocessor electronic controller with LED display for the

management of refrigerated compressed air dryers. The refrigerated dryers

managed by PJS8* Dryer are equipped with ON/OFF compressors.

Available supply voltages of easy dryer are 230 Vac, 115 Vac or 12 Vac-Vdc

PJS8* is suitable for controlling dryers with independent management of the compressor

(evaporator probe) and the condenser fan (condenser probe) in the 3-relay version PJS8C*.

Condensate drainage is activated by a relay controlled at fixed intervals, depending

on a specific parameter, independently of the activation of the compressor and fan. The

condensate drain function operates continuously when the unit is ON.

On PJS8Y* models equipped with two relays only, the compressor and fan are managed

using the same relay (with a single probe on the evaporator), and the condensate drain

function is managed by its own relay based on the set times (default setting). Alternatively,

the compressor and condenser fan can be managed separately as on the 3-relay model, in

which case the condensate drain function will no longer be managed by PJS8* Dryer.

The condensate drain relay is sized for a valve with a power consumption of 18 W and cosφ

> 0.7

Operation

PJS8* manages compressor operation based on the value read by the evaporation

temperature probe (probe 1, dew point). The controller manages different operating modes

and temperature ranges. At pre-set intervals (parameter dr2), the condensate is drained,

activated by relay 1 on the models where this is available.

Initialization: At power ON or when switching from OFF -> ON using the button or via digital

input, the compressor remains off for the time set by parameter “c0”, the controller then

switches to Normal operation.

Normal operation:This mode is active when the value read by probe 1 (dew point) is greater

than the threshold set for StL. The compressor operates as normal in this mode.

ECO: This mode is active when the temperature read by probe 1 falls below the threshold

set for StL and remains below the threshold for a minimum time, set for tE. The compressor

is off. ECO mode ends when the temperature rises above the threshold set for StH, causing

the compressor to start.

OFF: The controller is still powered on, however all of the functions of the algorithm are

disabled, including the condensate drain function.

Fan: The condenser fan is activated based on the settings of F4 and F5.When the compressor

is started the first time, the fan will start at F4 + 0.2 degrees to compensate for rapid increases

in temperature. Subsequently, the fan switches on and off at F4 + F5 and F4. By setting F6 =

1, probe 2, the fan and the related alarms are disabled.

Condensate drain: The drain relay is activated at pre-set time intervals. This controls a

valve to drain the condensate. The activation interval and the opening time depend on the

settings of dr1 and dr2. The valve can be activated manually by pressing the DOWN/DRAIN

button.

Alarms

ALARM TYPE CONDITIONS EFFECTS

High dew point Compressor running see alarms

and signals

table

probe 1 value greater than“Adp” for the time “tdp”

Probe 1 dew point probe 1 value exceeds the faulty probe limits

(-50.0/+90.0°C)

High temperature compressor stopped

probe 1 value greater than“dh1”for the time “dtH”

Low temperature with

compressor OFF

compressor stopped

probe 1 value less than“L1” for the time “tL”

Note: this alarm is only monitored after switching from OFF -> ON using the

button, during the compressor OFF time“c0”.

Low temperature with

compressor ON

compressor running

probe 1 value less than“L2” for the time “tL”

Condenser probe 2 probe 2 value exceeds the faulty probe limits

(-50.0/+90.0°C)

Alarms and signals table

Alarm message compressor fan valve buzzer reset

ECO mode ECO OFF Depends on

probe 2 Timed OFF automatic

High dew point Adp OFF Depends on

probe 2 Timed ON manual

Condensate drain drn Independent Depends on

probe 2 Timed OFF automatic

Dew point probe

alarm P1 ON Depends on

probe 2 Timed ON automatic

Condenser probe

alarm P2 ON Depends on

probe 2 Timed ON automatic

High temperature

alarm H1 ON Depends on

probe 2 Timed ON automatic

Low temperature

with compressor OFF L1 OFF Depends on

probe 2 Timed ON automatic

Low temperature

with compressor ON L2 OFF Depends on

probe 2 Timed ON manual

External alarm AI OFF OFF closed ON Automatic

OFF status OFF OFF OFF closed OFF Automatic

Unit parameter error EE OFF OFF OFF OFF Call techni-

cal service

Operating parameter

error EF OFF OFF OFF OFF

Manual

with factory

reset

Probe 1 temperature reading

There are three temperature ranges displayed, defined by the pair of parameters“r5”and

“r6”:

• Temperature between r5 and r6: the display shows the message“On”. Pressing Up+Set

for 2 seconds, the temperature is displayed for 30 seconds.

• Temperature lower than r5 or higher than r6: the display shows the actual value read by

the probe, filtered with a suitable coefficient to avoid sudden changes or instability of

the displayed value.

Logging

The controller can log some variables of interest to the user and make them available on

the user interface.

Par. Description UOM Min. Max. Default Visibility Note

ECd Percentage of ECO mode in

the last /3 hours % 0 100 0 C Read-only

ECY Percentage of ECO mode

since last reset % 0 100 0 C Read-only

ECh No. of hours in ECO mode

since last reset hours 0 32000 * 0 C Read-only

Ch No. of hours with compressor

ON since last reset hours 0 32000 * 0 C Read-only

Mh Total unit hours hours 0 32000 * 0 C Read-only

ndP Number of high dew point

alarms - 0 999 0 C Read-only

nH1 Number of high temperature

alarms - 0 999 0 C Read-only

nL1 Number of low temperature

with compressor OFF alarms - 0 999 0 C Read-only

nL2 Number of low temperature

with compressor ON alarms - 0 999 0 C Read-only

* When the hours exceed 999, the display shows a decimal point, indicating that the value

is to be multiplied by x1000.

Example: 3.3 = 3300 hours; 12.8 = 12800 hours

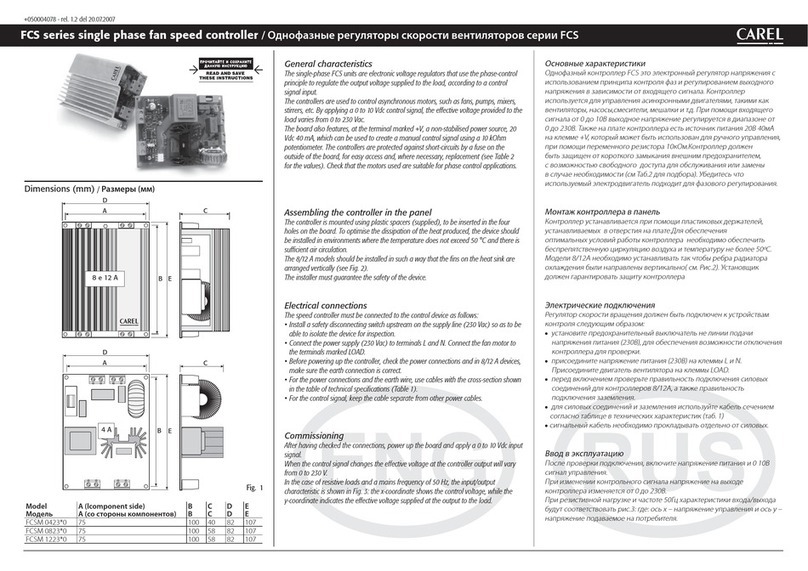

Electrical connections

Fig. 4

1 2

3

4 5 6

7

9 10 118

L

L N

8(4)A 10(10)A EN60730-1

8A 2FLA 12LRA 12A 10FLA 60LRA UL 873

COND. T.

DI / NTC

D.P.T.

NTC

PROBES

or

SERIAL

CONV

PROG.

KEY

-10T50

250 Vac

230 Vac/

or 115 Vac/

or 12 Vac/Vdc

PJS8C0H**

1 2 3 4 5 6 7

9 10 118

L

L N

8(4)A 10(10)A EN60730-1

8A 2FLA 12LRA 12A 10FLA 60LRA UL 873

DEF. T.

DI / NTC

AMB. T.

NTC

PROBES

or

SERIAL

CONV

PROG.

KEY

-10T50

250 Vac

230 Vac/

or 115 Vac/

PJS8Y0H**

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

Technical specications

power supply (*) 230 Vac +10 /-15% 50/60 Hz; 115 Vac +10 /-15% 50/60 Hz

12 Vac +10/-15% 50/60 Hz class 2; 12 Vdc +10/-20% class 2

nominal power 3.5 VA

inputs (*) NTC probe 1 or 3 inputs.

Digital input as an alternative to a third probe

relay outputs (*) 2 Hp relay UL: 12 A Res. 10 FLA 60 LRA - 240 Vac

EN60730-1: 10(10) A 250 Vac (**)

8 A relay UL: 8 A Res. 2 FLA 12 LRA - 240 Vac C300,

EN60730-1: 8(4) A NO, 6(4) A NC, 2(2) A CO - 250 Vac

probe type (*) NTC Std CAREL 10 KΩa 25 °C

connections (*) Plug-in terminals for screw blocks or with crimped contact (cable cross-

sect. up to 2.5 mm²). Rated maximum current per terminal 12 A.

assembly (*) using screws from the front panel or with rear brackets

Display 3 digit LED display with sign (-199 to 999) and decimal point; six status

LEDs

operating conditions -10T50 °C - humidity <90% RH non-condensing

storage conditions -20T70 °C - humidity <90% RH non-condensing

range of measurement -50T90 °C (-58T194 °F) - resolution 0.1 °C/°F

front ingress protection panel mounting with gasket: IP65 type 1

Case plastic terminal, 81x36x65 mm

class of protection against electric shock Class II when correctly incorporated

environmental pollution Normal

PTI of insulating material 250 V

period of stress across the insulating

parts Long

heat and fire resistance category category D (UL94 - V0)

surge protection immunity category 1

type of action and disconnection relay contacts 1C

no. of relay automatic switching ope-

rations (*) EN60730-1: 100.000 operations

UL: 30.000 operations (250 Vac)

software class and structure Class A

cleaning use only neutral detergents and water.

maximum cable length serial: 1 km; probes: 30 m; relays: 10 m

WARNING:

do not run power cables less than 3 cm from the bottom of the device or from the probes;

use only copper cables for the connections.

(*) The characteristics indicated differ according to the model.

(**) Minimum T OFF between two motor starts must be greater than 60 s..

IMPORTANT WARNING

The CAREL product is a state-of-the-art product, whose operation is specified in the technical documenta-

tion supplied with the product or can be downloaded, even prior to purchase, from the website www.carel.

com. The customer (manufacturer, developer or installer of the final equipment) accepts all liability and risk

relating to the configuration of the product in order to reach the expected results in relation to the specific

final installation and/or equipment. Failure to complete such operations, which are required/indicated in the

user manual, may cause the final product to malfunction; CAREL accepts no liability in such cases. The custo-

mer must only use the product in the manner described in the documentation relating to the product. The

liability of CAREL in relation to its products is specified in the CAREL general contract conditions, available on

the website www.CAREL.com and/or by specific agreements with customers.

Parameter Table

Simb. Parametro Carel

Type

Carel

Address

Modbus

Type

ModBus® Visibility Min. Max. Def. UoM

PS Password I 20 reg 148 F 0 200 22

/2 Measurement stability I 21 reg 149 C 1 15 4

/3 Number of hours to monitor Ecd I 22 reg 150 C 1 24 8

/4 Selection of the displayed probe I 23 reg 151 C 1 3 1

/5 Selection °C / °F (0 = °C; 1 = °F) D 31 coil 31 C 0 1 0

/6 Disable decimal point D 32 coil 32 C 0 1 0

/C1 Calibration probe 1 A 9 reg 9 C -12,7 -12,7 0,0 °C/°F

/C2 Calibration probe 2 A 10 reg 10 C -12,7 -12,7 0,0 °C/°F

StL Low dew point setpoint A 12 reg 12 C -2 100 0,0 °C/°F

StH Upper dew point setpoint A 13 reg 13 C 0,0 100,0 12,0 °C/°F

L1 Low temperature alarm threshold with

compressor OFF A 14 reg 14 C -50,0 200,0 2,0 °C/°F

L2 Low temperature alarm threshold with

compressor ON A 15 reg 15 C -50,0 200,0 -2,0 °C/°F

r5 Lower display limit A 16 reg 16 C -2,0 r6 3,0 °C/°F

r6 Upper display limit A 17 reg 17 C r5 200,0 7,0 °C/°F

tE ECO mode activation time I 25 reg 153 C 1 199 60 min

tE1 Minimum time of ECO mode I 26 reg 154 C 1 199 5 min

tL Low temperature alarms activation

time I 29 reg 157 C 0 90 2 sec

c0 Start delay of compressor and fan

at power on I 32 reg 160 C 0 200 1 min

c1 Minimum time between consecutive

compressor starts I 33 reg 161 C 0 100 3 min

c2 Compressor minimum off time I 34 reg 162 C 0 100 1 min

c3 Compressor minimum on time I 35 reg 163 C 0 100 0 min

c4 Compressor safety (duty setting) I 36 reg 164 C 0 100 0 min

dr1 Condensate drain time I 38 reg 166 F 1 20 1 sec

dr2 Drain time interval I 39 reg 167 F 3 60 6 min

d/ Probe 2 reading A 1 reg 1 C 0 0 0 °C/°F

dC Time base (reserved) D 37 coil 37 C 0 1 0

Adp High dew point alarm threshold A 24 reg 24 C 1 100,0 17,0 °C/°F

tdp Adp activation delay I 47 reg 175 C 0 60 6 min

h1 High temperature alarm threshold

with compressor ON A 25 reg 25 C -50,0 200,0 50,0 °C/°F

tH h1 activation time I 48 reg 176 C 0 90 30 sec

A4 Digital input configuration I 49 reg 177 C 0 2 0

F0 Fan ON delay I 61 reg 189 C 1 100 3 sec

F4* Fan off temperature A 28 reg 28 C -50 200 40 °C/°F

F5* Fan on differential A 29 reg 29 C 0,1 100 1 °C/°F

F6* Disable fan probe I 62 reg 190 C 0 1 0

H0 Serial address I 65 reg 193 C 0 207 1

H2 Enable keypad I 66 reg 194 C 0 3 1

H4 Disable buzzer D 39 coil 39 C 0 1 0

H5 Key ID code from supervisor I 67 reg 195 C 1 199 199

EZY Select Easy set bank I 68 reg 196 C 0 4 0

(*) parameters not present on models with 2 relays.

Note: the “Easy Set” parameter can be used to select one of the 4 quick configuration sets

stored on the device, each containing a maximum of 25 parameters.

Table of functions activated by button

Button Normal operation Start up

Pressed alone Pressed in combination Pressed

alone

Pressed in

combination

Up-On Off more than 3 s: switch

ON/OFF

Pressed

together,

activate

the

manual

alarm

RESET pro-

cedure

- -

Down-

Drain

more than 3 s:

activate/deactivate

condensate drain

Pressed

together,

display the

logged

variables

for 1 s

display

firmware

version

Pressed

together,

activate

the default

parameter

RESET

procedure

Set - more than 3 s:

access the parameter

setting menu (enter

password‘22’)

- Mute audible alarm

(buzzer)

- Reset logged

variables

for 1 s

RESET

current

EZY set

Access and set type F (frequent) and type C (configuration) parameters)

1. press SET for 3 s (the display will show“PS”);

2. • to access the type F and C parameter menu, enter the password “22”using UP/DOWN;

• to access the F parameter menu only, press SET (without entering the password);

3. scroll the parameter menu using UP/DOWN;

4. to view/set the values of the displayed parameter, press SET, then UP/DOWN and finally

SET again to confirm the changes (thus returning to the parameter menu)

To confirm and save all of the new values and exit the parameter menu, press and hold SET

for 3 s;

To exit the menu without saving the new values (exit by timeout), do not press any button

for at least 60 s.

Supervisor protocol on RS485 network

Automatic recognition of the network protocol: Carel or Modbus®

Accessories

• CAREL IROPZKEY* programming key (for duplicating the parameters)

• CAREL IROPZ48500 RS485 converter (for the RS485 supervisor network)

• CAREL CVSTDUMOR0 USB/RS485 converter for interfacing an RS485 network to a perso-

nal computer via the USB port

• VPM, program downloadable from http://ksa.carel.com. This tool can be used to set-up

the controller from a computer, program the parameters and update the firmware

Safety instructions

complies with the relevant European standards.

Installation precautions:

• the connection cables must guarantee insulation up to 90 °C;

• for 12 Vac versions use class II transformers. To comply with EN 61000-4-4, EN 61000-4-5,

EN 61000-4-11, EN 61000-4-6, EN 60730-1, the transformer must be one of the models

indicated (see the CAREL price list). For the 12 Vac/dc versions, as it is not possible to

guarantee double insulation between the power connectors and the relay outputs, it

is recommended to only use safety extra low voltage loads (nominal effective value up

to 42 V);

• allow a space of at least 10 mm between the case and nearby conductive parts;

• digital and analogue input connections less than 30 m; adopt the appropriate cable

separation measures to comply with the aforementioned regulations.

• Secure the output connection cables so as to avoid contact with safety extra low volta-

ge parts.

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

WARNING: separate as much as possible the probe and digital

input signal cables from the cables carrying inductive loads and

power cables to avoid possible electromagnetic disturbance.

Never run power cables (including the electrical panel wiring)

and signal cables in the same conduits.

Disposal of the product

The appliance (or the product) must be disposed of separately

in accordance with the local waste disposal legislation in force.