J2

S1

S2Y2

Y1ID1

ID2

NTCNTC

NTC

S5

S3 5V

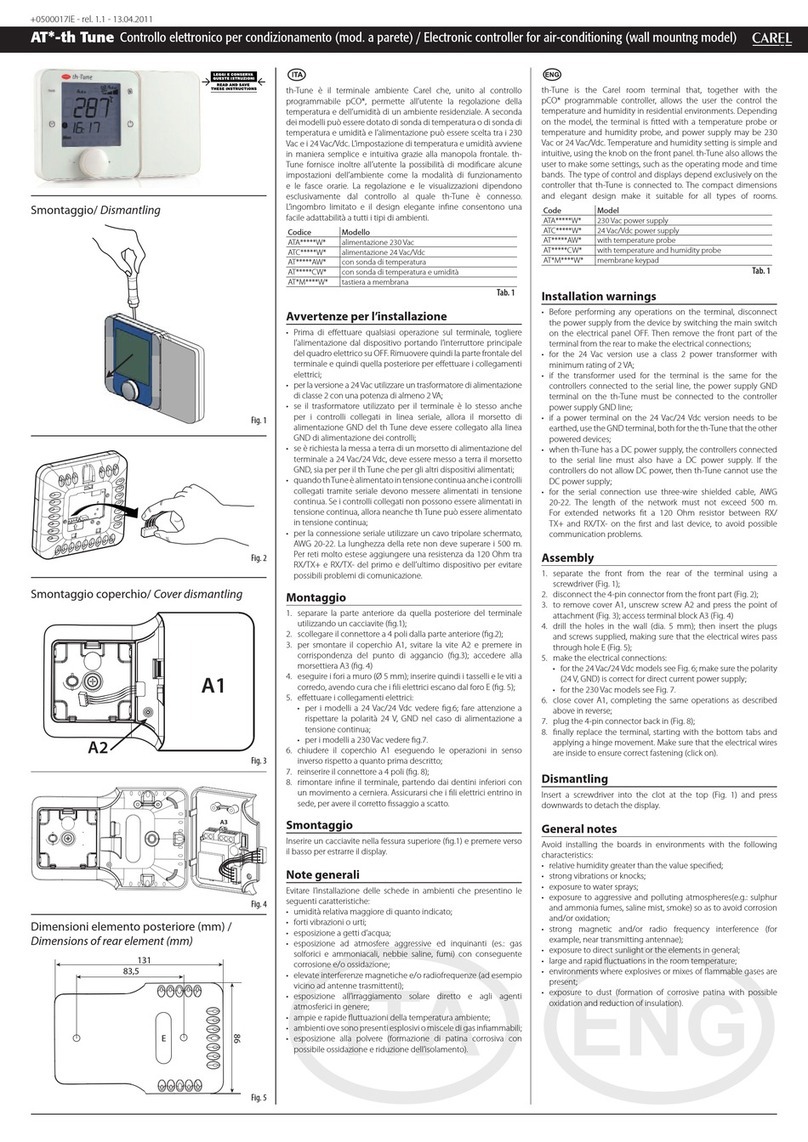

将控制器放到开孔中,轻轻按下侧面的卡扣,然后是前盖板,直到

控制器完全插入(侧面卡扣将弯曲,卡钩将控制器固定在面板上)。重

要:前盖板防护等级

IP65仅当下列条件满足后才能达到:

• 矩形开孔与水平面最大偏差:≤ 0,5 mm;

• 电控板金属片厚度:0.8 …2 mm;

• 应用垫圈的表面的粗糙度:≤ 120 μm。

注意:用于制造电控板的金属片厚度(或材料)必须足够确保安全和稳

定的安装产品。

Place the controller in the opening, press lightly on the side tabs and then on the front until fully inserted

(the side tabs will bend, and the catches will attach the controller to the panel). Important: IP65 front pro-

tection is guaranteed only if the following conditions are met:

•

maximum deviation of the rectangular opening from at surface: ≤ 0.5 mm;

•

thickness of the electrical panel sheet metal: 0.8-2 mm;

•

maximum roughness of the surface where the gasket is applied: ≤ 120 μm.

Note: the thickness of the sheet metal (or material) used to make the electrical panel must be adequate to

ensure safe and stable mounting of the product.

面板安装型 /

PANEL MOUNTIG MODEL

从后面打开盖板然后按住卡扣然后取

下控制器

重要:此操作无需使用螺丝

刀或其它工具

尺寸/ Dimensions - mm (in)

安装 / Mounting

尺寸/ Dimensions-

mm(in)

安装 / Mounting

装配 /Disassembly

DIN导轨安装型 / DIN RAIL MOUNTIG

接线 / WIRING CONNECTION

连接:面板安装型 / Connection: panel mounting

连接:DIN导轨安装型 / Connection: DIN rail mounting

传感器连接(所有型号) / Probe connection (all mod.)

NTC传感器连接

NTCprobe connection

公制比率式传感器连接/Ratiometric probe connection

4-20mA传感器连接/4-20mA probe connection

0-10 Vdc NTC传感器连接

0-10 Vdc NTCprobe connection

Important: during the rst connection, Applica aligns itself with the soft-

ware version on the µChiller controller via a cloud connection; this means a

mobile data connection is needed at least for this rst connection.

Fig. 2

COMMISSIONING

The procedure for initial commissioning is described below.

PREPARATION

Before conguring the unit the rst time, access KSA (ksa.carel.com), select

the “Congurations” folder and:

1. for the Chiller Standard and Enhanced models (with On/O compressor)

select the“Refrigerants”section and then the refrigerant charged in the unit;

2. for HE models (with BLDC compressor), import the BLDC conguration, se-

lecting the “BLDC compressors” section and then the brand and model of

compressor installed on the unit (this already includes the refrigerant setting)

3. import the downloaded conguration into the mobile device.

CONFIGURATION

1. start Applica and access the Manufacturer and Service proles;

2. select Set-up -> Conguration and click the + icon (see image)

3. use the menu (Fig. a) to select and apply the desired conguration;

4. select Unit Set-up (Fig. b) to proceed with the complete conguration (Fig c).

abc

ALARM TABLE

Code Description

A001 Unit: no. permanent memory writes

A002 Unit: permanent memory writes

A003 Unit: remote alarm from digital input

A004 Unit: remote set point probe

A005 Unit: user return water temperature probe

A006 Unit: user delivery water temperature probe

A008 Unit: user pump 1 overload

A009 Unit: user pump 2 overload

A10 Unit: ow switch (with user pump 1 active)

A11 Unit: ow switch (with user pump 2 active)

A12 Unit: user pump group

A13 Unit: user pump 1 maintenance

A14 Unit: user pump 2 maintenance

A15 Unit: high chilled water temperature

A16 Unit: source return water/air temperature probe

A17 Unit: source pump 1 maintenance

A18 Unit: free cooling warning

A19 Circuit 1: discharge pressure probe

A20 Circuit 1: condensing temperature probe

A21 Circuit 1: suction pressure probe

A22 Circuit 1: evaporation temperature probe

A23 Circuit 1: discharge temperature probe

A24 Circuit 1: suction temperature probe

A25 Circuit 1: high pressure switch

A26 Circuit 1: high pressure transducer

A27 Circuit 1: low pressure transducer

A28 Circuit 1: frost protection evaporation temperature

A30 Circuit 1: compressor 1 overload

A31 Circuit 1: compressor 2 overload

A32 Circuit 1: compressor 1 maintenance

A33 Circuit 1: compressor 2 maintenance

Code Description

A34 Circuit 1: source fan maintenance

A35 EVD circuit 1: LowSH

A36 EVD circuit 1: LOP

A37 EVD circuit 1: MOP

A38 EVD circuit 1: motor error

A39 EVD circuit 1: emergency closing

A40 EVD circuit 1: incomplete valve closing

A41 EVD circuit 1: oine

A42 Circuit 1: envelope alarm + zone alarm

A43 BLDC circuit 1: high pressure dierential at start-up

A44 BLDC circuit 1: failed start-up

A45 BLDC circuit 1: low pressure dierential

A46 BLDC circuit 1: high gas discharge temp.

A47 Speed drive 1: oine

A48 Speed drive 1: alarm + error code

A49 Unit: slave oine

A50 Slave unit: no. permanent memory writes

A51 Slave unit: permanent memory writes

A52 Circuit 2: discharge pressure probe

A53 Circuit 2: condensing temperature probe

A54 Circuit 2: suction pressure probe

A55 Circuit 2: evaporation temperature probe

A56 Circuit 2: discharge temperature probe

A57 Circuit 2: suction temperature probe

A58 Circuit 2: high pressure switch

A59 Circuit 2: high pressure transducer

A60 Circuit 2: low pressure transducer

A61 Circuit 2: frost protection evaporation temperature

A63 Circuit 2: compressor 1 overload

A64 Circuit 2: compressor 2 overload

A65 Circuit 2: compressor 1 maintenance

A66 Circuit 2: compressor 2 maintenance

A67 Circuit 2: source fan maintenance

A68 EVD circuit 2: LowSH

A69 EVD circuit 2: LOP

A70 EVD circuit 2: MOP

A71 EVD circuit 2: motor error

A72 EVD circuit 2: emergency closing

A73 EVD circuit 2: incomplete valve closing

A74 EVD circuit 2: oine

A75 Circuit 2: envelope alarm + zone alarm

A76 BLDC circuit 2: high pressure dierential at start-up

A77 BLDC circuit 2: failed start-up

A78 BLDC circuit 2: low pressure dierential

A79 BLDC circuit 2: high gas discharge temp.

A80 Speed drive circuit 2: oine

A81 Speed drive circuit 2: alarm + error code

TECHNICAL SPECIFICATIONS (for both models)

Technical specications, μChiller PANEL and DIN

Physical specications

Dimensions See gures

Case Polycarbonate

Assembly UCHBP*: panel models;

UCHBD*: DIN rail models

Ball test temp. 125°C

Ingress protection IP20 (rear,panel model)

IP65 (front, panel model)

IP00 (DIN version)

Front cleaning Use soft, non-abrasive cloth and neutral detergent or water

Environmental conditions

Operating conditions -20T60°C, <90% RH non-condensing.

Storage conditions -40T85°C, <90% RH non-condensing.

Electrical characteristics

Rated power supply voltage Provided by SELV or PELV Class 2 power supply

Oper. power supply voltage 24 Vac/dc, +10% -15%;

Input frequency 50/60Hz

Max current draw 600 mArms

Min power consumption 400mW

Clock precision ± 50ppm; date/time retention after

shutdown: 72h

Software class and structure A

Environmental pollution

Class of protection against

electric shock

To be incorporated into class I or II appliances

Type of action and discon. 1.C

Rated impulse voltage relay output: 4kV; 24 V input: 0.5 kV

Surge immunity category relay output: III; 24 V input: II

Control device construction Device to be incorporated

Terminal block Plug-in male-female.

Wire sizes: see the connector table

Purpose of the control Electrical operating control

User interface

Buzzer Panel: integrated

DIN: not included on the controller, integrated on the user terminal

Display LED 2 rows, decimal point, and multi-function icons

Open the electrical panel from the rear and press the anchor-

ing tabs and then the controller to remove it.

Important: The operation does not require

the use of a screwdriver or other tools.

备注/Note: = GND

Connectivity

NFC Max distance 10mm, variable according to the

mobile device used

Bluetooth Low Energy Max distance 10m, variable according to the

mobile device used

BMS serial interface Modbus over RS485, not opto-isolated

FieldBUS serial interface Modbus over RS485, not opto-isolated

HMI interface Modbus over RS485, not opto-isolated

Analogue inputs (Lmax=10m)

Ref.

J2 S1, S2, S3: NTC NTC: resolution 0.1° C; 10k @ 25°C;

error: ±1°C in the range -50T50°C,

±3°C in the range 50T90°C

0-10 V: error 2% fs, typical 1%

4-20mA: error 5% fs, typical 1%

0-10 V: error 2% fs, typical 1%

S5: 0-5V rat /4-20 mA / NTC

J3

S4: 0-5V rat /4-20 mA / NTC

S6: NTC / 0-5 Vrat / 0-10 V /

4-20 mA

J9 S7: NTC -

available only on

DIN version

Digital inputs

Ref.

J2 ID1

(*)

Voltage-free contact, not opto-isolated, typical

closing current 6 mA,

open contact voltage 13 V,

contact resistance max 50 .

(*)

Fast digital input: 0-2 kHz; error 2% fs

J2 ID2

J3 ID3 (*), ID4, ID5,

J9 ID6

-

available only

on DIN version

Valve output

Ref.

J14

available only on DIN

version

CAREL E*V unipolar valve power supply: 13

Vdc, min. winding resistance 40

Analogue outputs

Ref.

J2 Y1, Y2 0-10V: 10 mA max

Digital outputs

Ref.

J6 NO1 (5A), NO2 (5A),

NO3 (5A), NO4 (5A)

5A: EN60730: 5 A resistive, 250 Vac, 50k

cycles; 4(1), 230 Vac, 100k cycles; 3 (1), 230

Vac, 100k cycles

UL60730: 5 A resistive, 250 Vac, 30k cycles;

1 FLA, 6 LRA, 250 Vac, 30k cycles; Pilot Duty

C300, 30k cycles

J7 NO5 (5A)

J11 NO6 (5A)-

available

only on DIN version

Note: the sum of the current drawn by NO1, NO2, NO3 and N04 must not

exceed 8A.

Emergency power supply

Ref.

J10 Ultracap module (optional, only available on

the DIN versions)

13 Vdc +/-10%

Probe and terminal power supply

5V 5 Vdc ± 2% to power the 0 to 5 V ratiometric probes. Maximum

current delivered: 10 mA protected against short-circuits

+V 8-11 V to power the 4-20 mA current probes. Max current

delivered: 25 mA protected against short-circuits

J8 13 Vdc ± 10% to power the user terminal

VL not used

Cable lengths

Analogue inputs/outputs,

digital inputs/outputs, probe

power

<10m (*) (**)

(*) in the panel version, if using the VL power

supply in household environments, the maxi-

mum cable length is 2 m.

(**) in the DIN version powered at 115 Vac,

if using +V in household environments, the

maximum cable length is 2 m.

Valve < 2 m, < 6 m with shielded cable

BMS and Fieldbus serial cables <500m with shielded cable

Conformity

Electrical safety EN/UL 60730-1, EN/UL 60335-1

Electromagnetic compatibility EN 61000-6-1, EN 61000-6-2, EN 61000-6-3,

EN 61000-6-4

Applications with ammable

refrigerant gases

EN/UL 60079-15, EN/UL 60335-2-34,

EN/UL 60335-2-40, EN/UL 60335-2-89

Wireless RED, FCC, IC