&217(176

,1752'8&7,21«««««««««««««««««««««««««««««««««««««««««««

*(1(5$/)($785(6

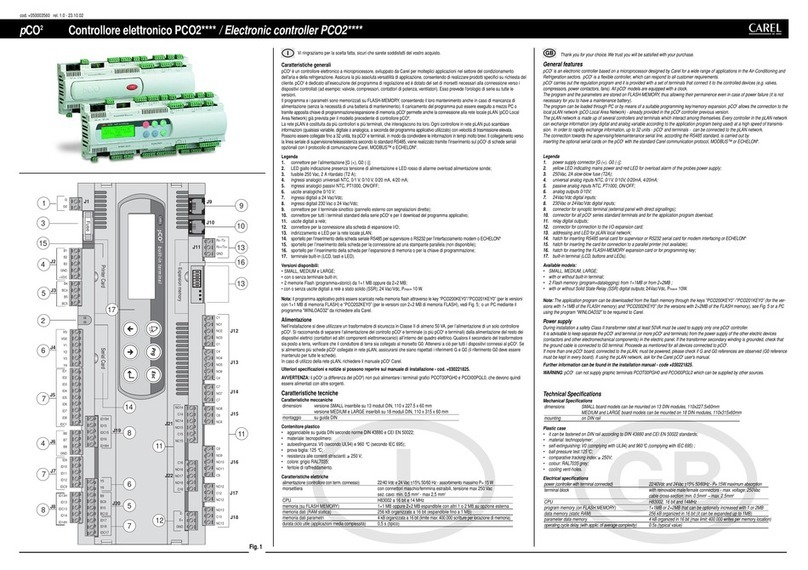

1.1 pCO2: SMALL, MEDIUM, LARGE.............................................................................................................................4

1.1.1 Features common to all the versions.............................................................................................................................4

1.1.2 Features of the individual versions................................................................................................................................4

1.2 Programmability............................................................................................................................................................5

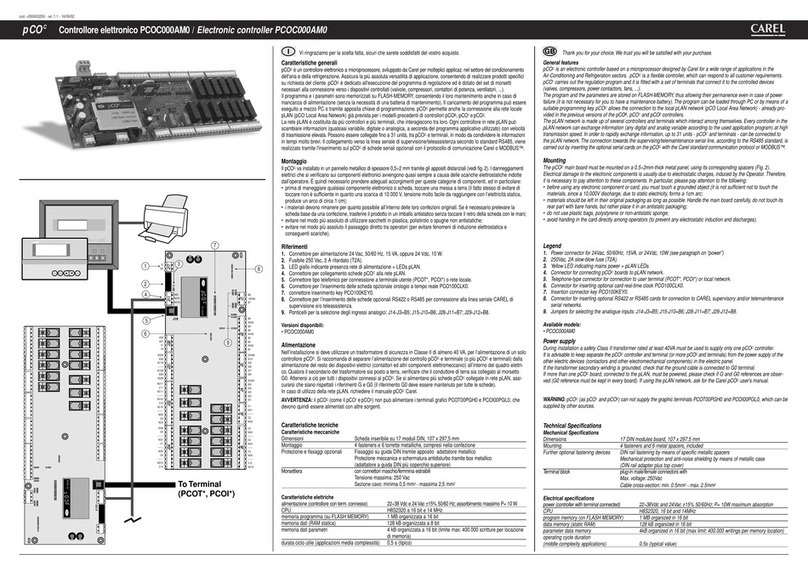

+$5':$5(6758&785(

2.1 Instrument and accessory codes....................................................................................................................................8

2.2 Meaning of the inputs/outputs.....................................................................................................................................10

7(50,1$/86(5

3.1 Contrast control in LCD Display.................................................................................................................................12

3.2 Display LCD 4x20 for wall or panel mounting...........................................................................................................12

3.3 LED Display for wall or panel mounting....................................................................................................................12

3.4 LCD Graphic Display for wall or panel mounting......................................................................................................12

3.5 4x20 LCD Display for panel mounting.......................................................................................................................13

3.6 LCD Graphic Display for panel mounting..................................................................................................................13

3.7 3-Digit Display - LED 32x72......................................................................................................................................13

3.8 Built-in display............................................................................................................................................................14

3.9 pCO terminal keypad ..................................................................................................................................................14

3.9.1 Typical use of the buttons in standard Carel applications...........................................................................................15

3.10 Functions and features of the terminal with graphic display......................................................................................15

3.10.1 Graphic display board.................................................................................................................................................16

3.10.2 Inverter card for powering the fluorescent light on the display (CFL) and connecting to the pCO2...........................16

3.10.3 Protective screen (optional printer card).....................................................................................................................16

,167$//$7,21

4.1 Anchoring the pCO2....................................................................................................................................................17

4.2 Power supply...............................................................................................................................................................17

4.3 Installation warnings - destination and connection environments...............................................................................17

4.4 Connecting the analogue inputs ..................................................................................................................................18

4.4.1 Connecting active temperature and humidity probes ..................................................................................................19

4.4.2 Connecting the universal NTC temperature probes ....................................................................................................20

4.4.3 Connecting the PT1000 temperature probes...............................................................................................................21

4.4.4 Connecting the pressure probes...................................................................................................................................22

4.4.5 Connecting the ON/OFF selectable analogue inputs...................................................................................................23

4.4.6 Table summarising the analogue inputs according to the available versions ..............................................................23

4.5 Connecting the digital inputs.......................................................................................................................................24

4.5.1 Digital inputs powered at 24Vac.................................................................................................................................24

4.5.2 Digital inputs powered at 24Vdc.................................................................................................................................25

4.5.3 Digital inputs powered at 230Vac...............................................................................................................................26

4.5.4 Table summarising the digital inputs according to the available versions...................................................................26

4.6 Connecting the analogue outputs ................................................................................................................................27

4.7 Connecting the digital outputs.....................................................................................................................................28

4.7.1 Electromechanical relay digital outputs ......................................................................................................................28

4.7.2 Solid state relay digital outputs (SSR) ........................................................................................................................29

4.7.3 Table summarising the digital outputs according to the available versions.................................................................29

4.8 Installing the user terminal..........................................................................................................................................30

4.8.1 Installing the wall/panel-mounting terminals (pCOT) and relative electrical connections..........................................30

4.8.2 Installing the panel-mounted terminals(pCOI) and relative electrical connections....................................................30

4.9 Installing the program EPROM in the terminal with graphic display .........................................................................31

S/$11(7:25.

5.1 Addressing the pCO2...................................................................................................................................................33

5.2 Addressing the terminals.............................................................................................................................................33

5.3 Private / shared terminals............................................................................................................................................34

5.4 pLAN electrical connections.......................................................................................................................................35

5.5 Remote installation of the terminal in a pLAN network..............................................................................................36

5.5.1 Remote terminal with pLAN network and telephone-type cable.................................................................................37

5.5.2 Remote terminal installation on pLAN network using AWG24 shielded cable with 3 twisted pairs + shield......................38

5.5.3 Remote installation of the terminal in a pLAN network with AWG20/22 shielded cables.........................................39

5.6 pLAN network technical specifications ......................................................................................................................39

237,21$/%2$5'6

6.1 Programming key........................................................................................................................................................40

6.2 Memory expansion......................................................................................................................................................40