Motor Controllers AC Variable Frequency Drives

Type Variflex3RVFF

Specifications are subjected to change without notice. 3

6.2 Reference from External Analog Signal (0-10V / 4-20mA)................................ 355

6.3 Reference from Serial Communication RS485 (00-05=3)..................................................357

6.4 Reference from two Analog Inputs.....................................................................................359

6.5 Change Frequency Unit from Hz to rpm ............................................................................359

Chapter 7 Operation Method Configuration (Run/Stop) ..................................360

7.1 Run/Stop from the Keypad (00-02=0) –Default Setting.....................................................360

7.2 Run/Stop from External Switch/Contact or Pushbutton (00- 02=1).....................................361

7.3 Run/Stop from Serial Communication RS485 (00-02=3)....................................................361

Chapter 8 Motor and Application Specific Settings.........................................363

8.1 Set Motor Nameplate Data (02-01, 02-05).........................................................................363

8.2 Acceleration and Deceleration Time (00-14, 00-15)...........................................................364

8.3 Torque Compensation Gain (01-10)..................................................................................365

8.4 Automatic Energy Savings Function (11-19)......................................................................366

8.5 Emergency Stop................................................................................................................368

8.6 Direct / Unattended Startup...............................................................................................369

Chapter 9 Using PID Control for Constant Flow/Pressure Applications.........372

9.1 What is PID Control?.........................................................................................................372

9.2 Connect Transducer Feedback Signal (10-01) ..................................................................374

9.3 Engineering Units..............................................................................................................375

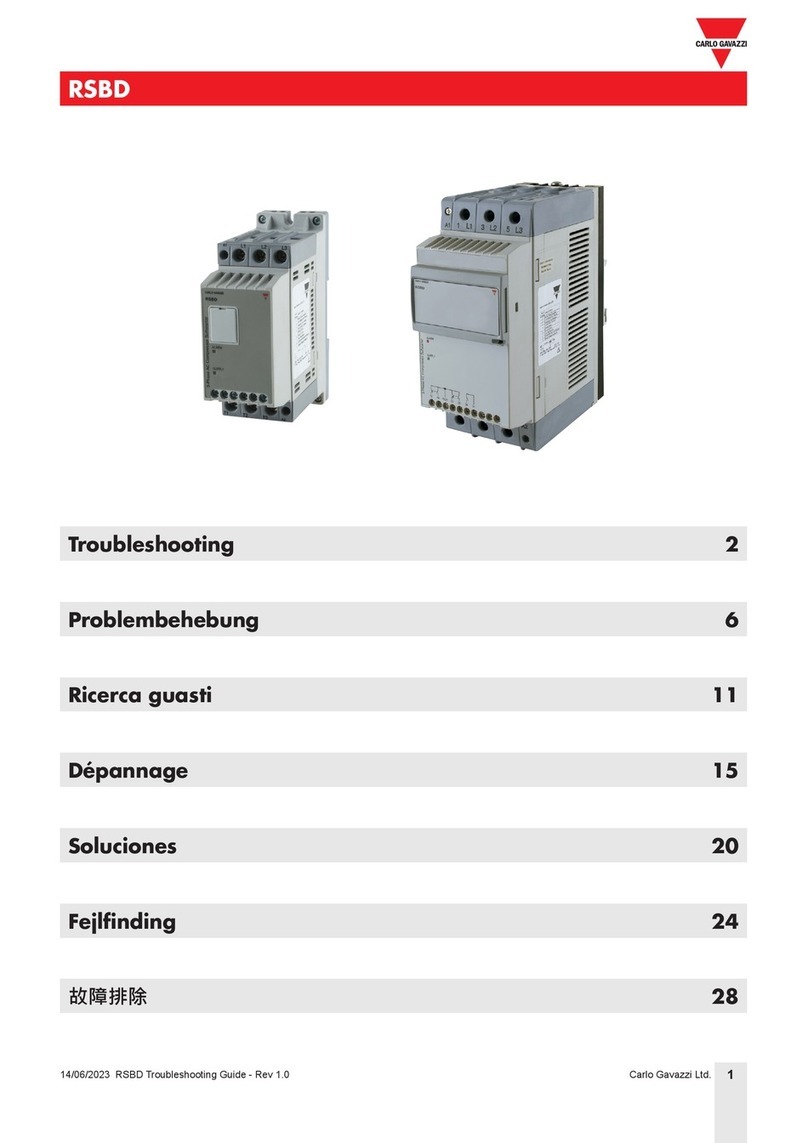

Chapter 10 Troubleshooting and Fault Diagnostics ........................................376

10.1 General ...........................................................................................................................376

10.2 Fault Detection Function..................................................................................................376

10.3 Warning / Self-diagnosis Detection Function ...................................................................382

10.4 Auto-tuning Error.............................................................................................................391

10.5 PM Motor Auto-tuning Error.............................................................................................392

10.6 General troubleshooting ..................................................................................................393

10.7 Troubleshooting of the inverter........................................................................................394

10.8 Routine and periodic inspection.......................................................................................401

10.9 Maintenance....................................................................................................................402

Chapter 11 Drive Peripheral devices and Options ...........................................403

11.1 Braking Resistors and Braking Units................................................................................403

11.2 AC Line Reactors ............................................................................................................404

11.3 Input Current and Fuse Specifications.............................................................................405

11.4 Other options...................................................................................................................406

11.5 Communication Options ..................................................................................................409

11.6 Profibus Communication Option Card..............................................................................410