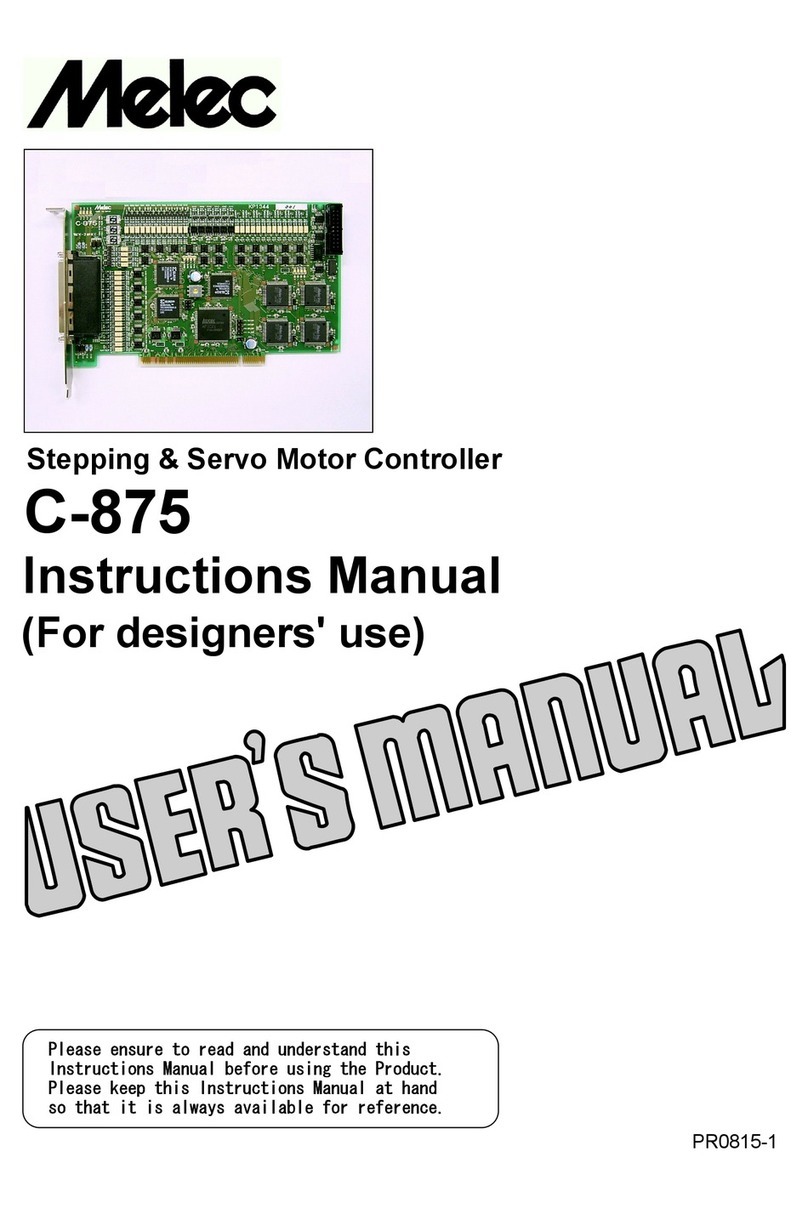

-4-

2C-776Av1

Instructions Manual

Overview1.

1-1. Features

The AL- series is a high speed serial communication system of original controlling the flexible stepping motor,●Ⅱ

servo motor which can cope easily as well and I/O in the decentralization of the device and supporting axial addition.

The AL- series is an insulation type high-speed serial communications of 20 Mbps/50 m or 10 Mbps/100 m.・Ⅱ

As a result, the saving wiring for the personal computer system can be attempted by the performance ratio of(

our company that equals a board controller so far.)

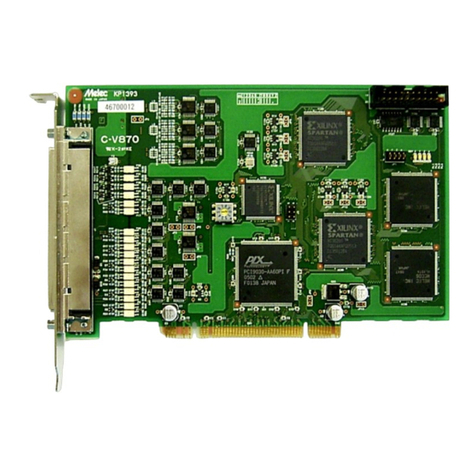

The shift of board controller C-VX870 series Device-function for PCI made of our company and the USB series・()

Device-function and Unit-function is easy depending on the device driver function for Windows.()

2C-776Av1 is a version up product with the 2C-776 upward compatibility.●The status of four axis batch reading and the command of four axis batch execution by the Unit-function became

possible. This Unit-function can perform a unit and AL- interface by one function execution from an application.Ⅱ

By this,

The time crunch can be done compared with accessed Device-function of each axis and I/O-function of・each I/O port.

The Unit-function writing suppresses the difference at time until it instructs time each axis and each I/O output・()

signal.

The Unit-function can reduce the load of the application.・It supports the Device-function, and can use the Device-function.・The Unit-function can be used together with the Device-function and the I/O-function.・

*1 The driver connection cable of 2C-776Av1 can correspond is only new ratings. Additionally, it is compatible with 2C-776.

Please refer to "Connection/ others " manual for the AL- series in detail.Ⅱ

Access example in Device-function and I/O-function Access example in Unit-function

Time lag

Reading X-axis STATUS1 X-axis STATUS1

Reading Y-axis STATUS1 Y-axis STATUS1

Reading Z-axis STATUS1 Z-axis STATUS1

Reading A-axis STATUS1 A-axis STATUS1

Time lag Batch Reading

Reading X-axis Control I/O A Unit X-axis Control I/O()

Reading Y-axis Control I/O Y-axis Control I/O

Reading Z-axis Control I/O Z-axis Control I/O

Reading A-axis Control I/O A-axis Control I/O

General-purpose I/O General-purpose I/OReading

Reading Extend I/O 0 Extend I/O 0

n

Reading Extend I/O 1 Extend I/O 1

o

n

i

o

t

Time lag

Batch Writing X-axis DATA1 X-axis DATA1

i

a

Each axis X-axis DATA2 X-axis DATA2

t

c

()

X-axis COMMAND -axis COMMAND

a

i

X

Batch Writing Y-axis DATA1 Y-axis DATA1

c

l

Each axis Y-axis DATA2 Y-axis DATA2

i

p

()

-axis COMMAND -axis COMMAND

l

p

Y Y

Batch Writing Z-axis DATA1 Z-axis DATA1

p

A

Each axis Z-axis DATA2 Batch Writing Z-axis DATA2

p

()

-axis COMMAND -axis COMMAND

A

ZAUnitZ()

Batch Writing A-axis DATA1 A-axis DATA1

Each axis A-axis DATA2 A-axis DATA2()

-axis COMMAND -axis COMMANDA A

Time lag

Writing X-axis Control I/O X-axis Control I/O

Writing Y-axis Control I/O Y-axis Control I/O

Writing Z-axis Control I/O Z-axis Control I/O

Writing A-axis Control I/O A-axis Control I/O

General-purpose I/O General-purpose I/OWriting

Writing Extend I/O 0 Extend I/O 0

Writing Extend I/O 1 Extend I/O 1