Step 2 -- Rig and Mount Unit

MOUNTING ON GI_.OUND M_unl und on a solkL level

(OTI_Wk" ptd Posilioll ufld so \_ll_l oI i(e I_oln 1(iol do_s ilo_

ldl dire_ll_ ohio unil Access_r_ shaking kils cm be used

_hell Llnds fie hi _X_ skKke(J _ee il]slai[ali(lll illshtl_[ioI1s

pm_Med _ilh Ihe a cessoJ_ kd Use fieM pm_ided sno_ sltnd

ol KU IKk _ [l_re plo[ongud subhuezillg le ml_'l ilules ol [1_*I\ _

Silo _\ O_( UIS

It ollddiolls or k_.aJ codes reqtlh e Lllli( bu hs R'l_ed k) a ptd,

6fiekl supplied liedo_\n I×)ll_ shouM I'_= used and Hsl_'nrd

Hlrough slol_ pro\ kk'd in uni_ mounli ng kx'l

MOUNTING ON ROOI Mounl uni[ /)n a level plall_)Hn

OI lllm_ _ tl lels[ 6 ill abo_e Iool suH I_e IsolaR* tIl_i[ ;uld lub

hlg horn ShU lure

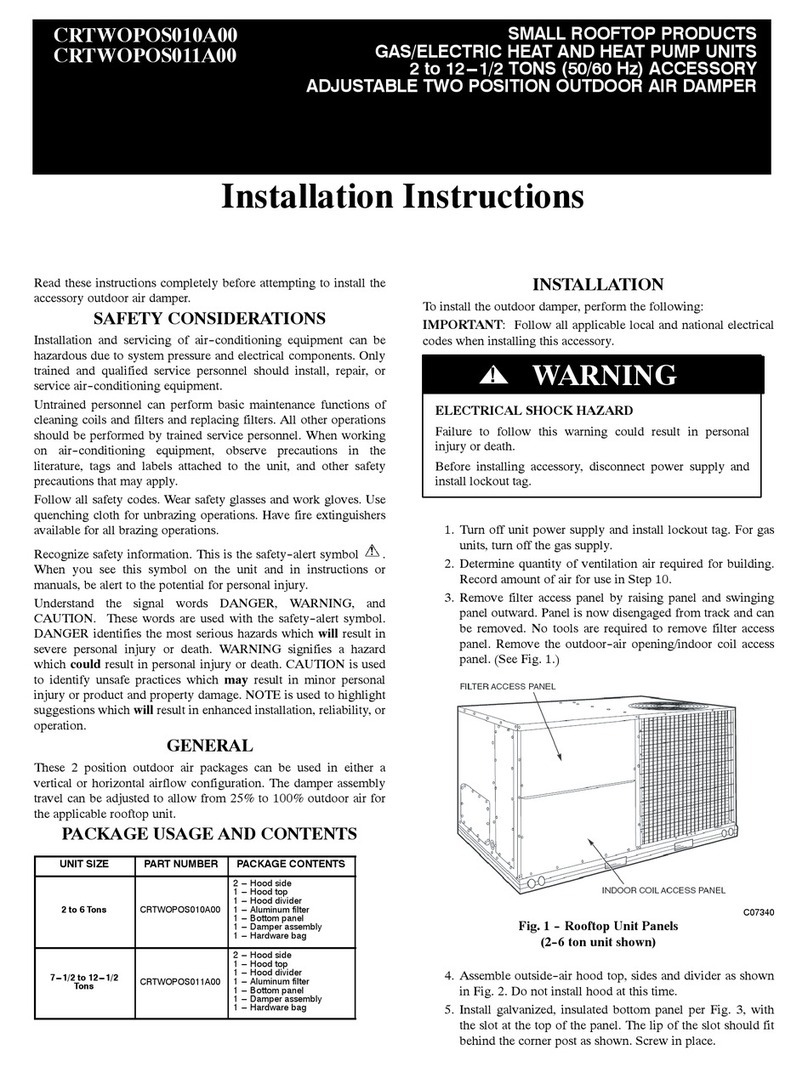

RIGGING

Keep Ihe unit updghl and lift unil using a sling Use card

board or p_lding tinder file sling, and sp_ader bars k) pl_venl

sling damage to the unit¸ See Fig 3 See Fig 2 _r cenler of

_avity re_nce Install the unit so thai Ihe _il does nol _ce

ink>pJ_vailing winds¸ Il¸Ibis is nol _>s_ible and constant wields

a_>ve 25 mph are ex_cl_l, use accessory wield baffle¸ See

inslallalion instructions p_)vid_d with the accessory ki_

NOTE: Accesso_ wind baffles should be us_l on all units

with access(_y low ambiel_t I_ll_pera[ul_2 coil ffol

Field _lbrica[ed sllow or ice slailds may be used to raise [lld[

when operation will be _quired during winler monlhs Units

ii_w also Ix'_wall motll_i_xl tlShlg Ihe acc_ssoly wall IllOUll[hlg

ki_

When mo_e Ihan 50 1}of flltercomlecthlg [ubing alld molv

Ihan 30 fi (If verlical lift is used. consult Ihe residenli fl long line

applicalhm inslmctkm gukie. Fo_ long Ihle _pplications. inler

connecting lines ove_ l(X) I_must be installed wilh a liquid line

solenoid A liquid line olenoid may a13o _v installed on some

unils to improve parl I(×ld eHlciency Reier to Ihe ARI (Air

Conditioning & Rehigeralion Insldule) Directory

II eilhe_ _cl_ig_ranl tubing o_ indoo_ coil is exposed Io

Ihe almosphem, the syslem mtlsl be evactHled lollowing go(_i

_efligcralion p_acfices

Run rehigemnl tulx's as direclly as possible, avoiding

unnecessary lu_ns and bends. Suspend _ehigcmnl lubes so they

do IIOI (hlmage illsula{ioll OI1 vapor [tll%" alld do IIOI[r_lllSl_li[

vibralion to strucltm" Also, when passing reMgerant tnlx:s

thmu_ a wall. seal Ihe opening so Ihal vibratkm is nol ImnsmiF

led to sffuctmv Ix'ave some slack in _vhi_erant tubes belween

sff[ic[lll_, alld ollld<×/i tlfli{ Io absorb vibratioll I_eler to separale

ind_ und inslallation instm_ {ions h_ additional inlbnnation

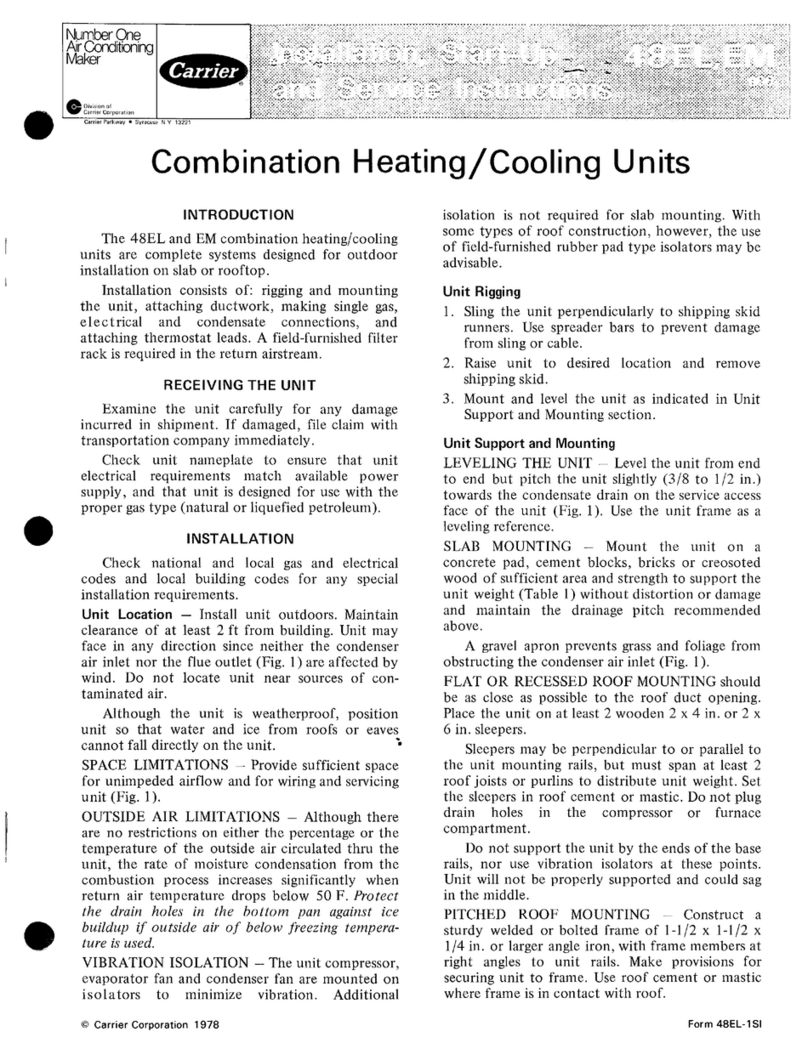

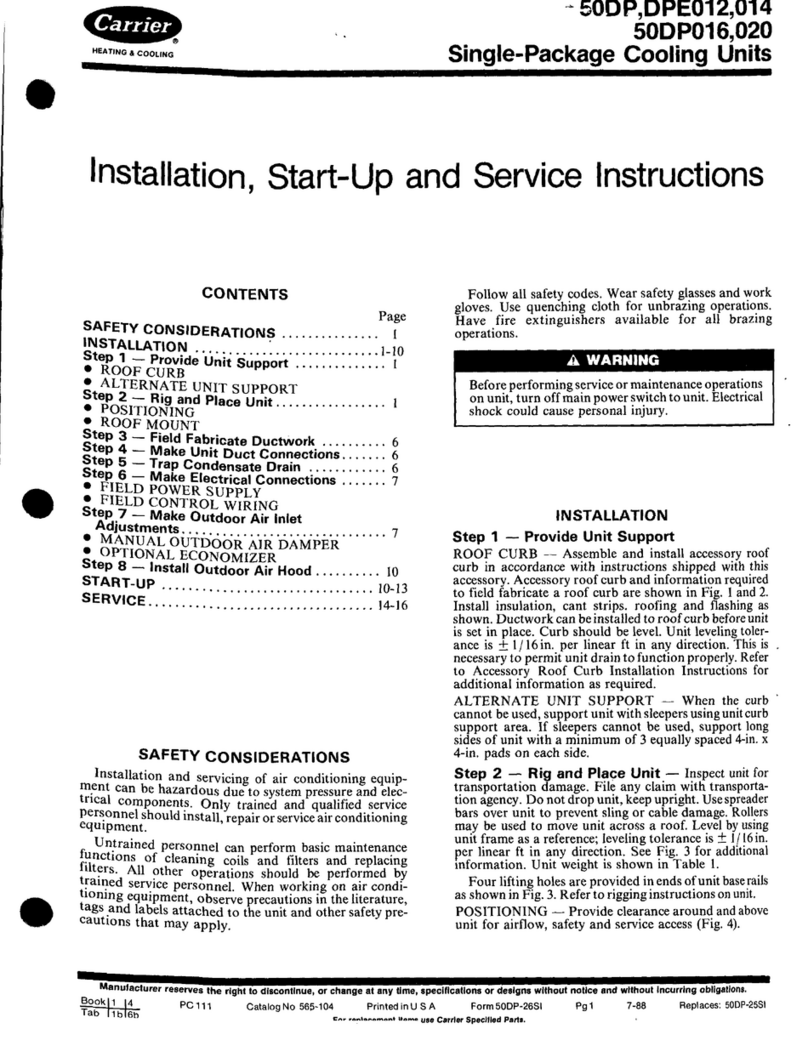

CHECK ACCURATERCONTROI, The correct Accu

Raler (byl_ass lylx') rehigeranl conhol is required h_r syslem

capaclly oplimization An AccuRaler device wilh field

_eplaceable pislon (see Elg 4) ix supplied wdh tile ouMoo_ und

Reler k/ tile AccuRaler metering device table in sepmale

indoor unil inslallation illsllucliOllS It) delermine fl_e cormcl

AccuRaler pislon SiZe requhvd Ibr [l_e condenser/evaix)rator

syslem being installed

Pisk)n slyle as shown in Elg 4 ix shipped wilh Ihe unfl Do

no[ ill[el_ha_lge coll_lN)llell[s beIwee_l the AcctlRaler device

types Matching of ould<x_ unil with indoor und may requhv

hekl rephcemenl of pislon I).epl _ce pislun, if required, _vl/>_v

_x/nnecfing _eldgemnl lines See Hg 4 Pislon _vplacemenl

illSIltlC[kH1S are hlcluded ill the indoo_ lind iilsl{dia[ioll ills{lilt

lions A[ler syslem inslallation is complele, see Ihe Rehigeranl

Chaffing section on page 12 to dleck and/or adlust _vffigelanl

cha_ [x"

FIUFER I)RIER The ldle_ drier mtlsI be _eplaced whenev

er Ihe _<'higeralion system is exposed to Ihe atmosphere See

Fig 4 lot filler drier inslallalion

;OMPRESSOR

CAP W_Ttl ORiFIGE gODy

NOTE: Arrow on AccuR_ter body points in free flow direction _w_y from tho

indoor coil¸

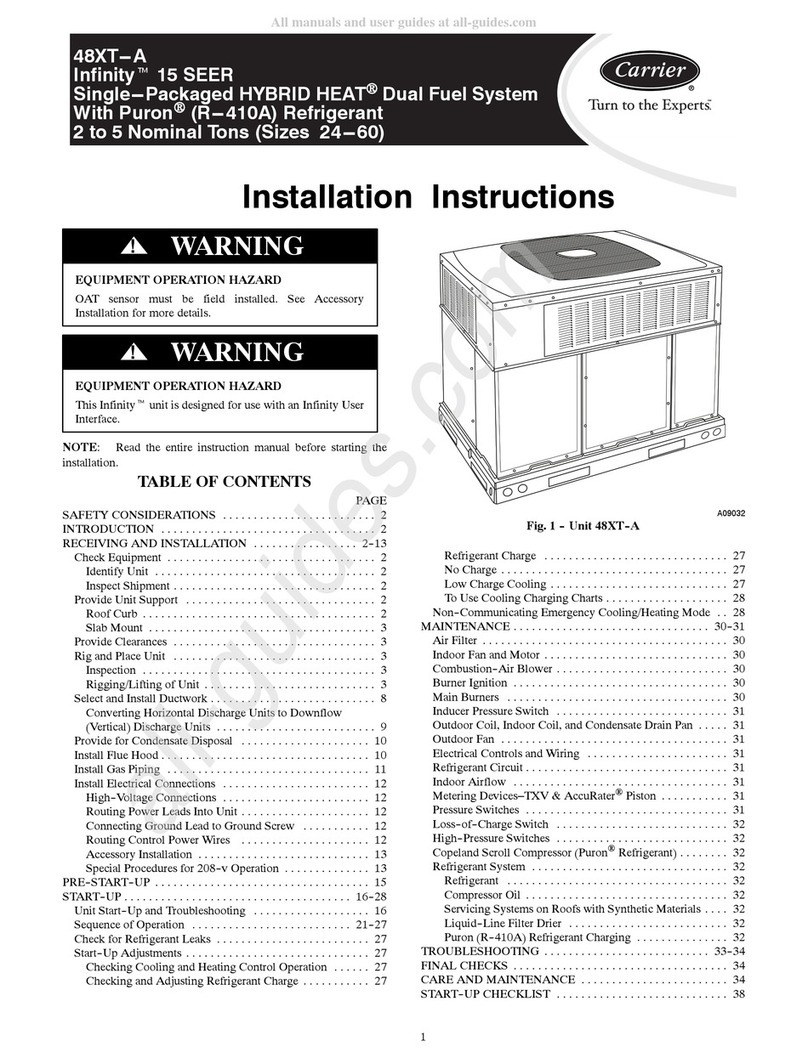

Fig. 3 -- Lifting Unit with Sling

Step 3 -- Complete Refrigerant Piping Con-

nections- Ou_d<×_unils ma_ b_, .)nnecled Io indoor

unds using fieki supplk'd [ubing ol _efiigeranl g_lde and ondi

Ik>n Sr_' "hbles IA and 1B tbr conec{ line sizes I)o nol use

less Ihan 10 I_ol ink'_ onneding lubing

(By OTHERS}

COBLINB

38HDFO18-036

_BYO_HE_

I)O NOT I3IIRY MORE THAN 36 IN OI REFRI( ER

AN[[" PIPE IN THE GROUND Il¸ any see{ion of pipe i_

buried. _l_ere mus_ be a 6 in vertical rise _(>the valve

collnec[iol_s o1_ the oukl(x)l ¸ uidL II ¸ 13lore thall [he

recommend_l lengfl_ ix buded reffi_ant may migrate to

cooler, bud_l section durhlg exlend_l _d(_s of syslem

shuMown This causes refii_ranl slugghlg and could

possibly dama_ Ihe comp_ssor al starl up

_B¥ aTHEgm

38HDR018-060

Fig. 4 -- AccuRater (Bypass Type) Metering

Device Components