• Section 2- (Page 12) Models 58WAV, 58PAV, 58ZAV, 58RAV, 395CAV, 383KAV, 376CAV, 373LAV, 393AAV, 58YAV, PG8UAA,

PG8DAA, 58DXT, 58TMA, 58TUA, 58UHV, 58UXT, 58UXV, 330AAV, 330JAV, 331AAV, 331JAV, 333BAV, and 333JAV 40-inch high,

Induced-Combustion, Hot-Surface Ignition, Single Stage, 2-Stage and Variable-Speed, Non-Condensing Furnaces. This kit is designed for use

in furnaces with 40,000 through 154,000 Btuh gas input rates.

• Section 3- (Page 19) Models 58MCA, 58MSA, 58MXA, 340MAV, 345MAV, 350MAV, 490AAV, and PG9MAA, 58MVP, 58MTA,

355MAV, and 352MAV, 4-Way Multipoise, Hot Surface Ignition, Condensing Furnaces. This kit is designed for use in furnaces with 40,000

through 140,000 Btuh gas input rates.

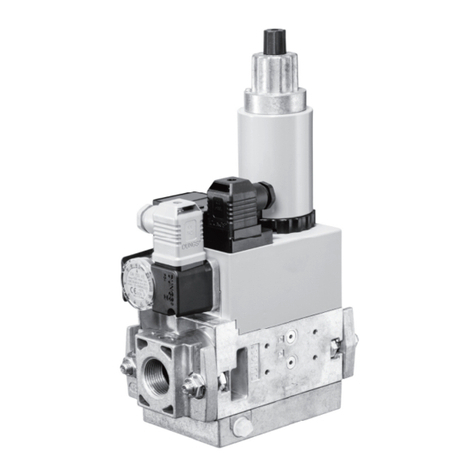

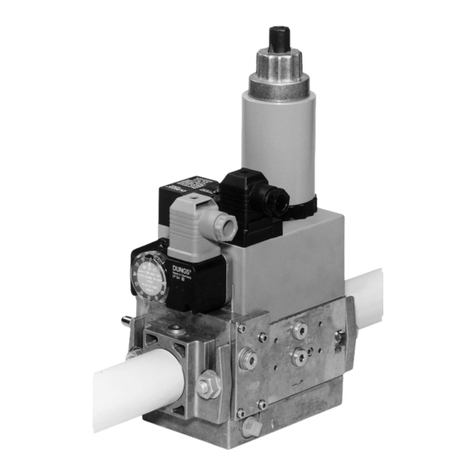

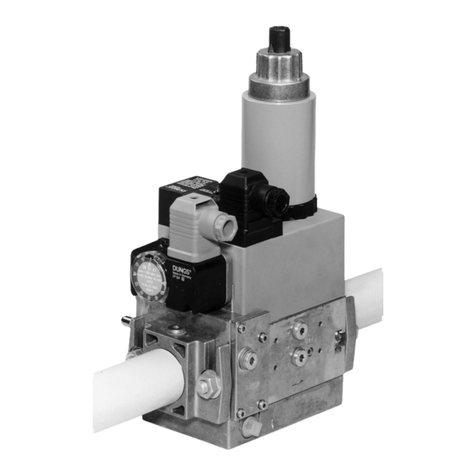

This kit is designed for use in the furnaces listed above. The gas valve will be a White-Rodgers 36E, 36F or 36G series gas valve with either an

electric control switch or a manual control knob.

IMPORTANT: This kit can replace conversion kit KGANP25012SP for furnaces listed in Sections 2 and 3, as specified on unit rating plate, when

gas valve is replaced with Two-Stage Gas Valve P/N EF33CW198 (White-Rodgers 36E55). Replacement gas valve is available through RCD.

WARNING: FIRE, EXPLOSION, ELECTRICAL SHOCK AND CARBON MONOXIDE POISONING HAZARD

Failure to follow instructions could result in serious injury, death or property damage.

Improper installation, adjustment, alteration, service, maintenance, or use can cause carbon monoxide poisoning, explosion, fire,

electrical shock, or other conditions, which could result in personal injury or death. Consult your distributor or branch for information

or assistance. The qualified installer or agency must use only factory-authorized kits or accessories when servicing this product.

WARNING: FIRE, EXPLOSION, ELECTRICAL HAZARD

Failure to follow this warning could result in serious injury, death or property damage.

Gas supply MUST be shut off before disconnecting electrical power and proceeding with conversion.

DESCRIPTION AND USAGE

This kit is designed for use in the furnaces listed above. See Table 1 for kit contents. To accommodate many different furnace models, more parts

are shipped in kit than will be needed to complete conversion. When installation is complete, discard extra parts.

→Table 1—Kit Contents

DESCRIPTION PART NO. QUANTITY

Main Burner Orifice (Drill Size 1.30mm) LH32DB210 7

Main Burner Orifice (Drill Size 1.25mm) LH32DB209 7

Main Burner Orifice (Drill Size No. 54) LH32DB203 7

Main Burner Orifice (Drill Size No. 55) LH32DB201 7

Main Burner Orifice (Drill Size No. 56) LH32DB206 7

Screw, Spoiler 327593-401 7

Diverter Plate 323184-301 1

Low Gas Pressure Switch (Propane) (LGPS) HK02LB008 1

Nipple CA52JZ103 1

90° Street Elbow (1/8 in.) CA15RA001 1

Male x Female x Female Tee (1/8 in.) CA21JZ001 1

Splice Connector (1/4 in. Male, Both Ends) 66175D55 1

Splice Connector (3/16 in. Male, Both Ends) HY89SC047 1

Orange Wire Assembly (18 in.) W182X23- -04- -018 2

Orange Wire Assembly (12 in.) W182X66- -04- -012 1

Yellow Wire Assembly (6 in.) W182Y66- -11- -006 1

Yellow Wire Assembly (14 in.) W182Y66- -11- -014 1

Yellow Wire Assembly (16 in.) W182Y66- -23- -016 1

Wire Tie HY76TB125 1

Conversion Rating Plate Label—Condensing Furnaces 327697-201 1

Conversion Rating Plate Label—Non-Condensing Furnaces 327697-204 1

Conversion Rating Plate Label—Non-Condensing Furnaces 327697-206 1

Conversion Rating Plate Label—Non-Condensing Furnaces 327697-204 1

Conversion Responsibility Label 327697-205 1

Gas Control Conversion Label (adjusted) 327697-202 1

Gas Control Conversion Label (converted) 327697-203 1

Installation Instructions AG-GANP-31 1

Regulator Spring Kit (White—Propane-EF39ZW023) for

White-Rodgers 36C, 36E, 36F and 36G Valve 92-0659 2

Drill Bit 328456-401 1

—2—

→

→