2

FIRE, EXPLOSION, ELECTRIC SHOCK, AND

CARBON MONOXIDE HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

This conversion kit shall be installed by a qualified service

technician in accordance with the Manufacturer’s instructions

and all applicable codes and requirements of the authority

having jurisdiction. The qualified service agency is

responsible for the proper installation of this kit. The

installation is not proper and complete until the operation of

the converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

!WARNING

General Information

This kit is for conversion of furnaces equipped with Honeywell

VR8205S Series 2--stage gas valves certified for use with Natural

Gas (and so marked) to units functionally the same as the certified

furnace for use with Propane Gas. Before the furnace can be

operated with Propane Gas, the Propane low pressure switch must

be installed. A gas valve conversion kit must be installed and main

burner orifices must be replaced with properly sized orifices.

The orifices provided in this kit are stamped to indicate the size

(twist drill number) and are sized for commercially pure propane

gas ONLY. Do NOT use them with butane or a mixture of butane

and propane gas. The parts list specifies the size orifices supplied in

the kit. Compare the size marking on the orifices with the sizes as

listed in the parts list. Make sure you have the correct main burner

orifices.

Extreme care is used to assure that this kit contains the proper

orifices. Oversized orifices could result in hazardous conditions,

especially if the venting is inadequate. For that reason, we

recommend that the installer check the size of the orifice with a

new twist drill of the correct size. This procedure assures that the

orifices provided are the correct size.

Installation

ELECTRIC SHOCK, FIRE, AND EXPLOSION

HAZARD

Failure to follow this warning could result in death, personal

injury, property damage and/or equipment damage.

Turn OFF gas supply at manual gas valve before turning OFF

electric power supply and starting conversion.

Turn OFF electric power supply at disconnect switch or

service panel before starting conversion.

!WARNING

Disassembly

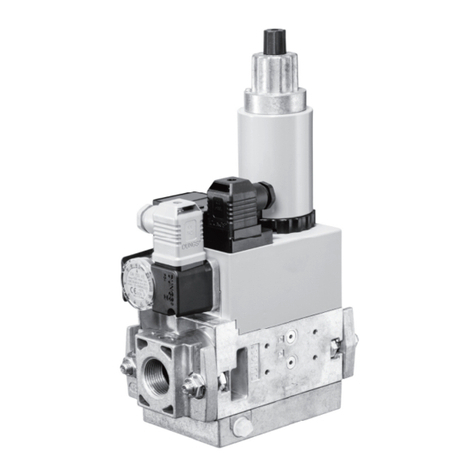

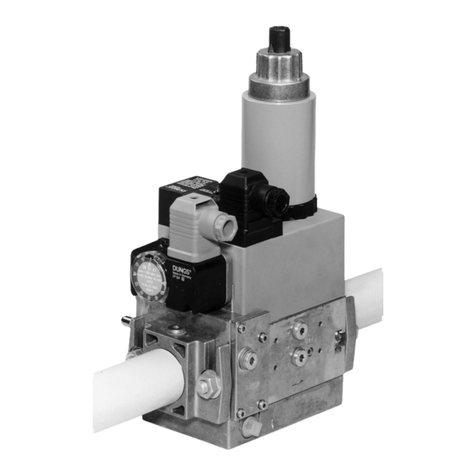

A07838

Fig. 1 -- Disassembly

Refer to Fig. 1 and the following steps.

1. After disconnecting power and gas supply to the furnace,

remove the access door, exposing gas valve and burner

compartment.

2. Disconnect gas line from gas valve so manifold assembly

can be removed.

3. Disconnect wiring at gas valve. Be sure to note the proper

location of any and all electrical wiring disconnected.

4. Remove the screws holding the manifold and gas valve to

the manifold supports. Do not discard any screws.

5. Carefully remove the manifold assembly.

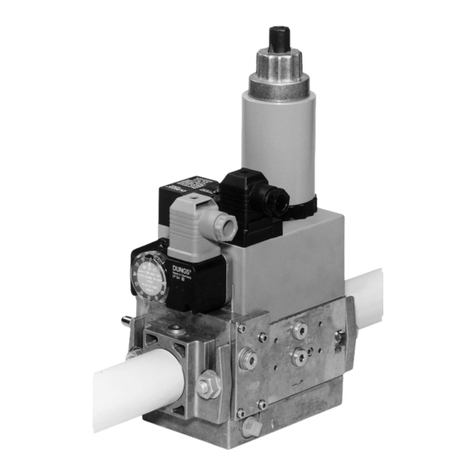

Main Burner Orifices

1. Remove the Natural gas burner orifices from the manifold

assembly and replace them with the appropriate Propane

(silver) orifices furnished in the conversion kit (Fig. 2),

unless converting a high altitude unit, then see Table 1 for

appropriate orifices.

A07839

Fig. 2 -- Remove Orifices

2. Tighten the orifices so they are seated and gas tight about

1--1/8″(28.6 mm) from the face of the orifice to the back of

the manifold pipe (Fig. 3). Make sure orifice is installed

straight so that it forms a right angle (90°) to the manifold.